-

Cangzhou Yulong Steel Co., Ltd.

-

Phone:

+86 13303177267 -

Email:

admin@ylsteelfittings.com

- English

- Arabic

- Italian

- Spanish

- Portuguese

- German

- kazakh

- Persian

- Greek

- French

- Russian

- Polish

- Thai

- Indonesian

- Vietnamese

- Zulu

- Korean

- Uzbek

- Hindi

- Serbian

- Malay

- Ukrainian

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Miao

- Hungarian

- Icelandic

- igbo

- irish

- Japanese

- Javanese

- Kannada

- Khmer

- Rwandese

- Afrikaans

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Esperanto

- Estonian

- Finnish

- Frisian

- Galician

- Georgian

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Dutch

- Punjabi

- Romanian

- Samoan

- Scottish Gaelic

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Turkish

- Turkmen

- Urdu

- Uighur

- Welsh

- Bantu

- Yiddish

- Yoruba

Oct . 12, 2024 06:00 Back to list

Weldable Steel Pipe Fittings for Versatile Industrial Applications and Enhanced Durability

Weldable Steel Pipe Fittings An Essential Component for Industrial Applications

Weldable steel pipe fittings are critical components in various industrial applications, enabling the effective and secure connections of piping systems. These fittings are designed to withstand high pressures and extreme conditions, making them a staple in industries such as oil and gas, water treatment, chemical processing, and construction. Understanding their types, benefits, and applications can provide valuable insights into their significance in modern engineering.

Types of Weldable Steel Pipe Fittings

Weldable steel pipe fittings come in a variety of shapes and sizes, each serving a unique purpose in piping systems. The most common types include

1. Elbows These fittings allow for directional changes in piping, typically at angles of 45 or 90 degrees. They are crucial for redirecting the flow of fluids within a system.

2. Tees Tees have a T-shaped design and are used to create branch connections in a piping system. They can divide the flow from one pipe into two, or vice versa.

3. Reducers These fittings help in transitioning between different pipe sizes. They are essential when connecting pipes of varying diameters to ensure a smooth flow and minimize turbulence.

4. Caps Used to seal the end of a pipe, caps are crucial for shutting down a section of a piping system or when the final operation is completed.

5. Couplings These fittings join two sections of pipe together, providing a secure connection that can withstand mechanical stresses.

Each type of fitting is designed with specific welding techniques in mind, allowing for seamless integration into various piping systems.

Benefits of Weldable Steel Pipe Fittings

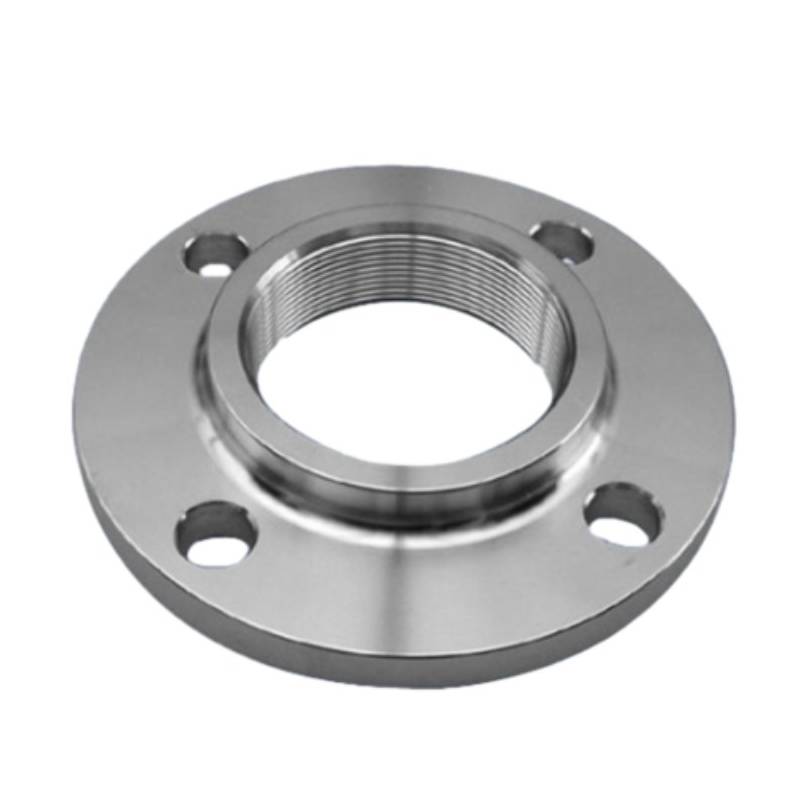

weldable steel pipe fittings

The use of weldable steel pipe fittings offers several advantages that enhance the performance and reliability of piping systems

1. Strength and Durability Weldable steel fittings are designed to withstand harsh conditions and high pressures, ensuring long-lasting performance. Their robust nature makes them suitable for demanding environments.

2. Corrosion Resistance Many weldable steel fittings are coated or made from materials that resist corrosion, which is essential in industries that deal with aggressive chemicals or moisture-laden environments.

3. Leak-Proof Connections Welding provides a strong, permanent bond between fittings and pipes, greatly reducing the risk of leaks that can lead to costly downtime and environmental hazards.

4. Versatility Due to their variety of shapes and sizes, weldable steel fittings can be customized to fit different piping configurations, making them adaptable to various industrial needs.

5. Cost-Effectiveness Although the initial investment may be higher than some alternatives, the long-term durability and reliability of welded connections often lead to cost savings in maintenance and replacements.

Applications of Weldable Steel Pipe Fittings

Weldable steel pipe fittings are used across numerous industries, each with specific requirements. In oil and gas, for example, these fittings are essential in transporting hydrocarbons safely. In water treatment facilities, they support the distribution of clean water while resisting corrosion from chemicals involved in the purification process. Similarly, in the construction sector, weldable fittings are vital for plumbing and HVAC systems, ensuring that infrastructure is intact and functional.

Conclusion

In conclusion, weldable steel pipe fittings are indispensable in modern industrial applications. Their ability to provide secure and durable connections, coupled with their resistance to various environmental factors, makes them essential components in a wide array of systems. As industries continue to evolve and face new challenges, the importance of reliable fittings like these will only increase, underscoring the need for quality materials and expert installation practices. Whether it’s for constructing new facilities or maintaining existing infrastructure, investing in high-quality weldable steel pipe fittings is a decision that pays dividends in safety and efficiency.

Latest news

-

ANSI 150P SS304 SO FLANGE

NewsFeb.14,2025

-

ASTM A333GR6 STEEL PIPE

NewsJan.20,2025

-

ANSI B16.5 WELDING NECK FLANGE

NewsJan.15,2026

-

ANSI B16.5 SLIP-ON FLANGE

NewsApr.19,2024

-

SABS 1123 FLANGE

NewsJan.15,2025

-

DIN86044 PLATE FLANGE

NewsApr.19,2024

-

DIN2527 BLIND FLANGE

NewsApr.12,2024

-

JIS B2311 Butt-Welding Fittings LR/SR 45°/90° /180°Seamless/Weld

NewsApr.23,2024