-

Cangzhou Yulong Steel Co., Ltd.

-

Phone:

+86 13303177267 -

Email:

admin@ylsteelfittings.com

- English

- Arabic

- Italian

- Spanish

- Portuguese

- German

- kazakh

- Persian

- Greek

- French

- Russian

- Polish

- Thai

- Indonesian

- Vietnamese

- Zulu

- Korean

- Uzbek

- Hindi

- Serbian

- Malay

- Ukrainian

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Miao

- Hungarian

- Icelandic

- igbo

- irish

- Japanese

- Javanese

- Kannada

- Khmer

- Rwandese

- Afrikaans

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Esperanto

- Estonian

- Finnish

- Frisian

- Galician

- Georgian

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Dutch

- Punjabi

- Romanian

- Samoan

- Scottish Gaelic

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Turkish

- Turkmen

- Urdu

- Uighur

- Welsh

- Bantu

- Yiddish

- Yoruba

Nov . 10, 2024 01:52 Back to list

Welded Tube Fittings Solutions for Reliable Connections in Piping Systems

Understanding Weld Tube Fittings Essential Components in Fluid Handling Systems

In the realm of fluid handling systems, weld tube fittings play a crucial role in ensuring the efficient transfer of liquids and gases. These fittings are essential for creating reliable connections between pipe segments, which is especially important in industries such as oil and gas, pharmaceuticals, food and beverage, and chemical processing. This article delves into the function, types, and advantages of weld tube fittings, showcasing why they are indispensable in modern engineering applications.

What Are Weld Tube Fittings?

Weld tube fittings are mechanical devices used to connect two or more tubes or pipes together. Unlike other types of fittings that rely on threads, gaskets, or adhesive, weld fittings achieve a secure connection using welding techniques. This method creates a strong, permanent bond that is resistant to leakage, making weld tube fittings ideal for high-pressure and high-temperature applications.

Types of Weld Tube Fittings

Weld tube fittings come in various types, each designed for specific applications and requirements. Some of the most common types include

1. Butt Weld Fittings These fittings are designed to be welded at the ends, creating a continuous pipe system. Butt weld fittings come in various shapes, including elbows, tees, and reducers.

2. Socket Weld Fittings Socket weld fittings are inserted into a socket and then welded in place. This type of fitting is typically used for small-diameter piping systems.

3. Flared Fittings Flared fittings feature a cone-shaped end that connects to a similarly shaped tube end. When tightened, the flared edges create a tight seal. These fittings are often used in high-pressure applications.

4. Crosses and Tees Cross and tee fittings allow for changes in direction or branching of the pipeline. These fittings can be butt-welded or socket-welded depending on the system requirements.

5. Caps and Plugs Used to close the ends of pipes, caps and plugs are essential for maintaining the integrity of a system during maintenance or testing.

weld tube fittings

Advantages of Weld Tube Fittings

1. Leakage Prevention One of the most significant advantages of weld tube fittings is their ability to create a leak-tight seal. The welding process fuses the materials together, minimizing the risk of leaks that can occur with threaded or glued connections.

2. High Resistance to Pressure and Temperature Weld fittings can withstand higher pressures and temperatures than many other fitting types, making them suitable for demanding industrial applications.

3. Durability The solid bond created by welding provides excellent durability. Weld tube fittings are resistant to vibration and mechanical stresses, which helps to extend the lifespan of piping systems.

4. Versatile Material Compatibility Weld fittings can be manufactured from various materials, including stainless steel, carbon steel, and alloys, allowing them to be used in a wide range of environments and industries.

5. Streamlined Flow Because weld fittings have smooth interior surfaces without any obstructions, they promote better fluid flow compared to threaded fittings, which can create turbulence.

Applications of Weld Tube Fittings

Weld tube fittings are widely used across various industries. Here are a few examples

- Oil and Gas Used in drilling and refining processes, weld fittings assist in transporting hydrocarbons efficiently. - Pharmaceuticals In pharmaceutical manufacturing, cleanliness is paramount. Weld fittings enable sterile connections, preventing contamination. - Food and Beverage Weld fittings are essential in food processing and beverage manufacturing, where hygiene is critical. - Chemical Processing The ability to withstand harsh chemicals makes weld fittings a reliable choice in chemical plants.

Conclusion

Weld tube fittings are fundamental components in the construction of robust and effective piping systems. Their ability to provide leak-proof, high-pressure connections makes them a preferred choice in various industries. By understanding the types and benefits of weld tube fittings, engineers and technicians can make informed decisions that enhance the efficiency and safety of fluid handling systems. As industries continue to advance, the demand for reliable and durable fittings will only grow, making weld tube fittings essential to future developments in engineering and manufacturing.

Latest news

-

ANSI 150P SS304 SO FLANGE

NewsFeb.14,2025

-

ASTM A333GR6 STEEL PIPE

NewsJan.20,2025

-

ANSI B16.5 WELDING NECK FLANGE

NewsJan.15,2026

-

ANSI B16.5 SLIP-ON FLANGE

NewsApr.19,2024

-

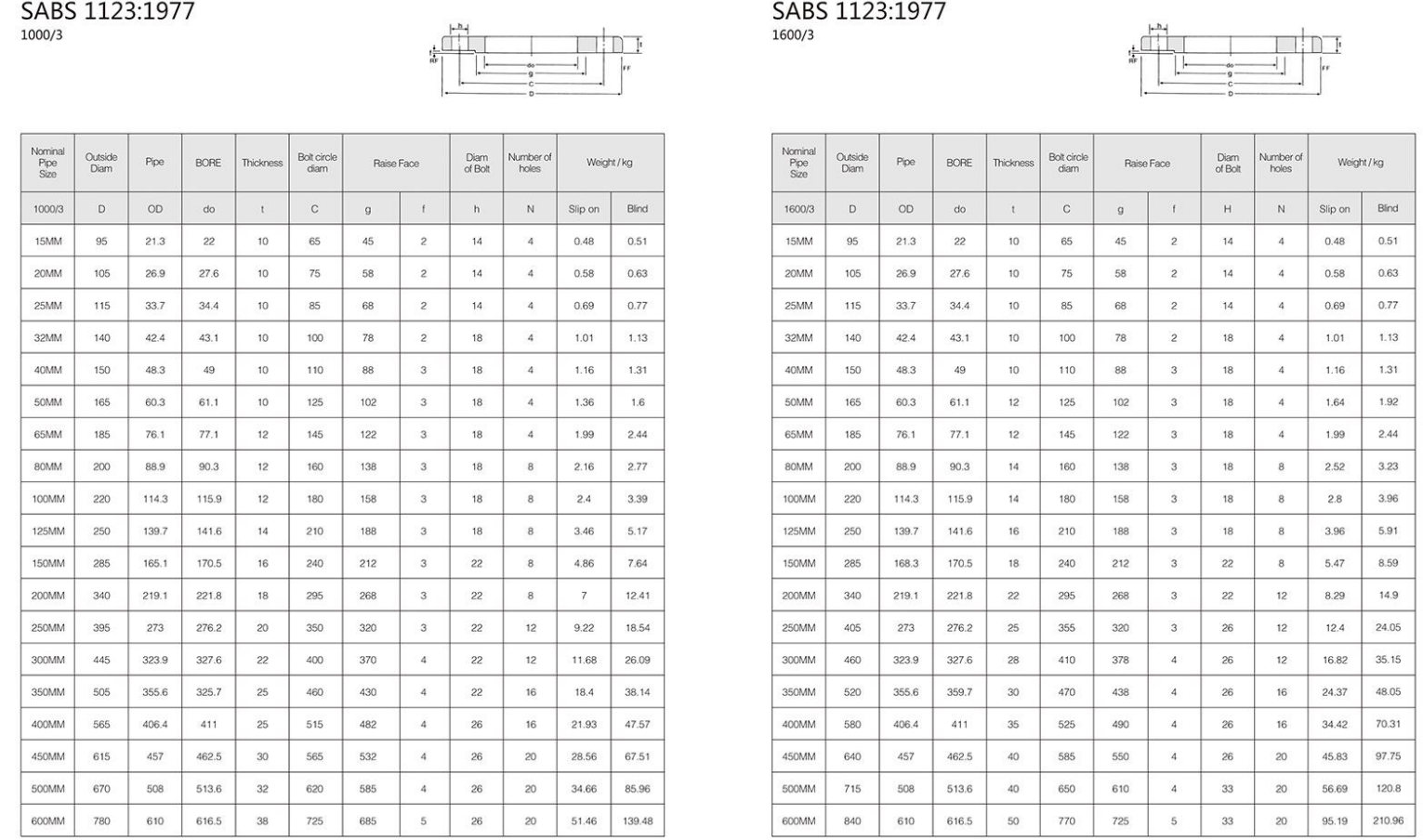

SABS 1123 FLANGE

NewsJan.15,2025

-

DIN86044 PLATE FLANGE

NewsApr.19,2024

-

DIN2527 BLIND FLANGE

NewsApr.12,2024

-

JIS B2311 Butt-Welding Fittings LR/SR 45°/90° /180°Seamless/Weld

NewsApr.23,2024