-

Cangzhou Yulong Steel Co., Ltd.

-

Phone:

+86 13303177267 -

Email:

admin@ylsteelfittings.com

- English

- Arabic

- Italian

- Spanish

- Portuguese

- German

- kazakh

- Persian

- Greek

- French

- Russian

- Polish

- Thai

- Indonesian

- Vietnamese

- Zulu

- Korean

- Uzbek

- Hindi

- Serbian

- Malay

- Ukrainian

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Miao

- Hungarian

- Icelandic

- igbo

- irish

- Japanese

- Javanese

- Kannada

- Khmer

- Rwandese

- Afrikaans

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Esperanto

- Estonian

- Finnish

- Frisian

- Galician

- Georgian

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Dutch

- Punjabi

- Romanian

- Samoan

- Scottish Gaelic

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Turkish

- Turkmen

- Urdu

- Uighur

- Welsh

- Bantu

- Yiddish

- Yoruba

Feb . 13, 2025 13:52 Back to list

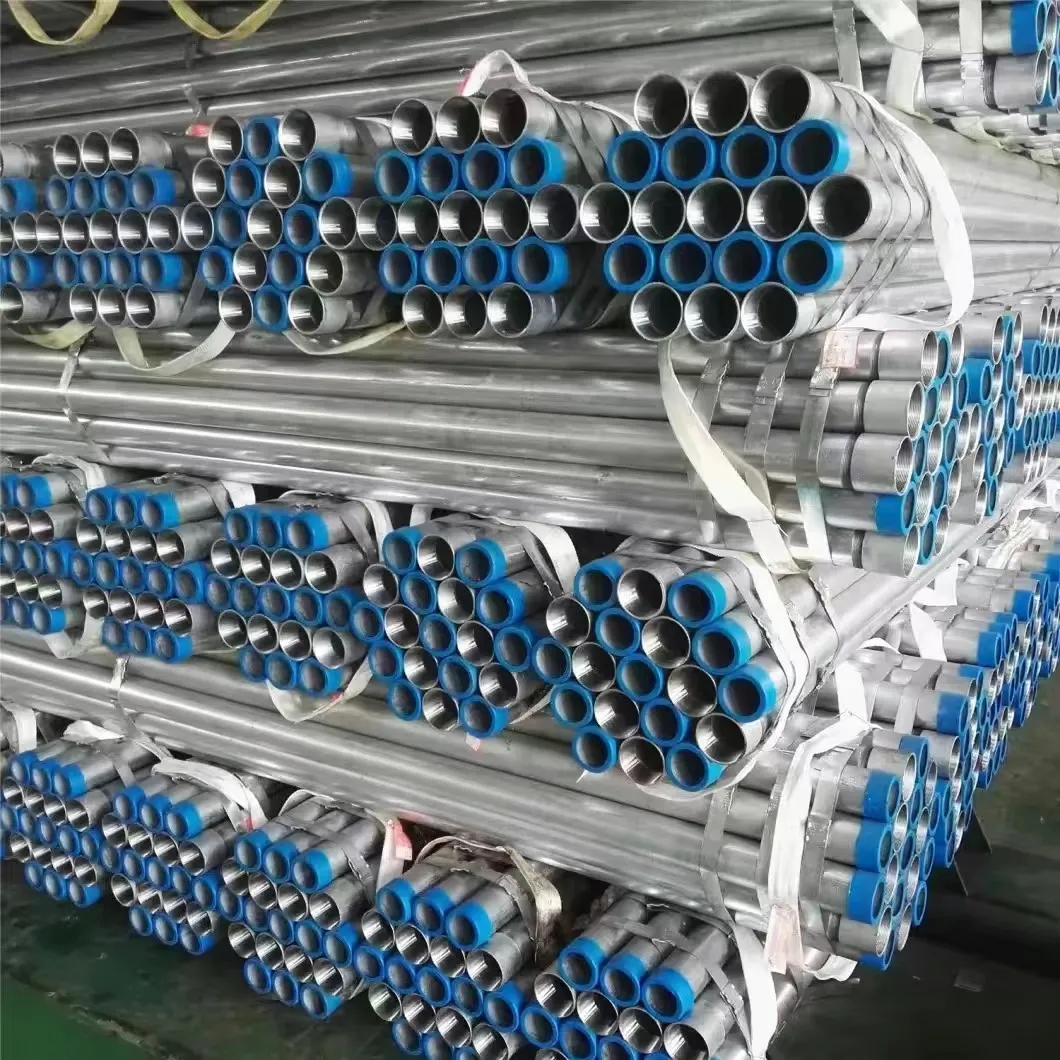

2 inch galvanized pipe for sale

When considering plumbing and construction, the choice of materials can significantly influence the durability, cost-effectiveness, and overall success of your project. One material that stands out is the 2-inch galvanized pipe, particularly the 20-foot variant, known for its robustness and extensive applications. This piece will explore the characteristics, advantages, and prudent applications of the 20-foot, 2-inch galvanized pipe, grounded in industry expertise and legitimate experiences.

Moreover, galvanization adds an authoritative element to structural applications. Buildings utilizing these pipes often meet stringent safety and building codes, thanks to their resilience and reliability. They can withstand harsh environmental factors, including high humidity and varying temperatures, making them ideal for outdoor or exposed installations. Real-life experience from project managers reveals a consistent theme trustworthiness in performance. Projects using 2-inch galvanized pipes for plumbing or structural support report fewer incidences of failure, translating to lower long-term maintenance costs. Their protective zinc coating reduces the risk of rusting, ensuring the integrity of water quality in plumbing systems—a critical factor for health and safety. In installation scenarios, these pipes are also lauded for their reliability. Contractors report fewer complications during installation, a direct result of the pipe's robust properties and manageable dimensions. This reliability is crucial in high-stakes projects where timelines are tight, and efficiency is paramount. However, while galvanized pipes forged from industry expertise offer manifold benefits, it's essential to consult with professionals to ensure their suitability for your specific needs, considering factors such as local environmental conditions and regulations. Trustworthy suppliers and experienced contractors can provide guidance tailored to your project. In conclusion, the 20-foot, 2-inch galvanized pipe stands as a benchmark in industrial and residential building materials. Its combination of strength, longevity, and corrosion resistance, backed by extensive field expertise, makes it a preferred choice for many construction and plumbing needs. When investing in these pipes, one secures not just a structural component but a promise of enduring quality and reliability, trusted by professionals across the globe.

Moreover, galvanization adds an authoritative element to structural applications. Buildings utilizing these pipes often meet stringent safety and building codes, thanks to their resilience and reliability. They can withstand harsh environmental factors, including high humidity and varying temperatures, making them ideal for outdoor or exposed installations. Real-life experience from project managers reveals a consistent theme trustworthiness in performance. Projects using 2-inch galvanized pipes for plumbing or structural support report fewer incidences of failure, translating to lower long-term maintenance costs. Their protective zinc coating reduces the risk of rusting, ensuring the integrity of water quality in plumbing systems—a critical factor for health and safety. In installation scenarios, these pipes are also lauded for their reliability. Contractors report fewer complications during installation, a direct result of the pipe's robust properties and manageable dimensions. This reliability is crucial in high-stakes projects where timelines are tight, and efficiency is paramount. However, while galvanized pipes forged from industry expertise offer manifold benefits, it's essential to consult with professionals to ensure their suitability for your specific needs, considering factors such as local environmental conditions and regulations. Trustworthy suppliers and experienced contractors can provide guidance tailored to your project. In conclusion, the 20-foot, 2-inch galvanized pipe stands as a benchmark in industrial and residential building materials. Its combination of strength, longevity, and corrosion resistance, backed by extensive field expertise, makes it a preferred choice for many construction and plumbing needs. When investing in these pipes, one secures not just a structural component but a promise of enduring quality and reliability, trusted by professionals across the globe.

Latest news

-

ANSI 150P SS304 SO FLANGE

NewsFeb.14,2025

-

ASTM A333GR6 STEEL PIPE

NewsJan.20,2025

-

ANSI B16.5 WELDING NECK FLANGE

NewsJan.15,2026

-

ANSI B16.5 SLIP-ON FLANGE

NewsApr.19,2024

-

SABS 1123 FLANGE

NewsJan.15,2025

-

DIN86044 PLATE FLANGE

NewsApr.19,2024

-

DIN2527 BLIND FLANGE

NewsApr.12,2024

-

JIS B2311 Butt-Welding Fittings LR/SR 45°/90° /180°Seamless/Weld

NewsApr.23,2024