-

Cangzhou Yulong Steel Co., Ltd.

-

Phone:

+86 13303177267 -

Email:

admin@ylsteelfittings.com

- English

- Arabic

- Italian

- Spanish

- Portuguese

- German

- kazakh

- Persian

- Greek

- French

- Russian

- Polish

- Thai

- Indonesian

- Vietnamese

- Zulu

- Korean

- Uzbek

- Hindi

- Serbian

- Malay

- Ukrainian

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Miao

- Hungarian

- Icelandic

- igbo

- irish

- Japanese

- Javanese

- Kannada

- Khmer

- Rwandese

- Afrikaans

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Esperanto

- Estonian

- Finnish

- Frisian

- Galician

- Georgian

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Dutch

- Punjabi

- Romanian

- Samoan

- Scottish Gaelic

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Turkish

- Turkmen

- Urdu

- Uighur

- Welsh

- Bantu

- Yiddish

- Yoruba

Feb . 15, 2025 18:14 Back to list

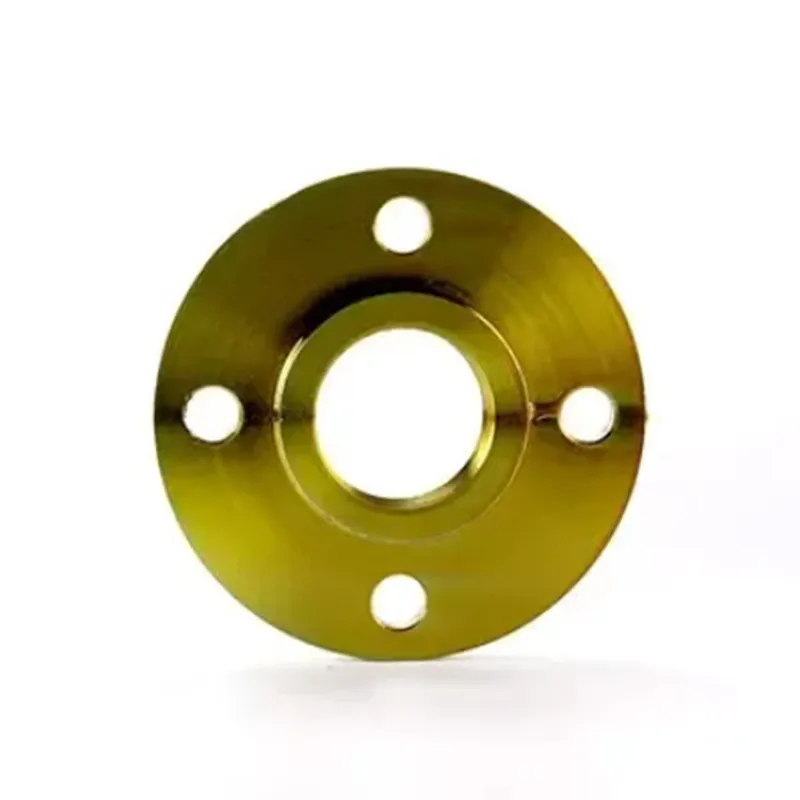

BS 4504 WELDING NECK FLANGE 111

Searching for a reliable flange manufacturer in China can be a challenge given the multitude of options available. However, with a keen understanding of industry standards and meticulous evaluation, procurement managers and engineers can find manufacturers whose products not only meet but exceed quality expectations. In this dynamic field, a handful of Chinese manufacturers have emerged as market leaders, demonstrating impressive expertise and credibility.

The authority of a manufacturer is often reflected in their client portfolio and the industry sectors they serve. Leading manufacturers in China often supply flanges to renowned multinational companies and participate in large-scale infrastructure projects. This level of engagement illustrates their trusted status and ability to meet demanding international standards and project deadlines. Trustworthiness is further enhanced by transparent business practices and a strong focus on client communication. Reputable manufacturers institute comprehensive testing protocols that include pressure testing, ultrasonic testing, and X-ray inspections. These measures ensure the structural integrity of each flange, reinforcing client confidence in product reliability. Strong logistical networks also play an essential role in the operational efficiency of Chinese flange manufacturers. With advanced supply chain management and strategic partnerships with key logistics providers, they ensure timely delivery of products worldwide. This capability is crucial in maintaining project schedules and minimising downtime, factors that significantly impact project costs and customer satisfaction. Before forging partnerships with flange manufacturers in China, interested parties should conduct detailed due diligence. This can involve requesting technical specifications, quality assurance certifications, client references, and facility audits. Through careful evaluation, businesses can secure partnerships that guarantee high-quality flange solutions, ultimately boosting their competitiveness in global markets. In conclusion, Chinese flange manufacturers are making significant strides in the global marketplace by blending traditional craftsmanship with cutting-edge technology. By prioritizing quality, customization, and customer satisfaction, these manufacturers not only uphold high standards but also build lasting relationships with clients worldwide.

The authority of a manufacturer is often reflected in their client portfolio and the industry sectors they serve. Leading manufacturers in China often supply flanges to renowned multinational companies and participate in large-scale infrastructure projects. This level of engagement illustrates their trusted status and ability to meet demanding international standards and project deadlines. Trustworthiness is further enhanced by transparent business practices and a strong focus on client communication. Reputable manufacturers institute comprehensive testing protocols that include pressure testing, ultrasonic testing, and X-ray inspections. These measures ensure the structural integrity of each flange, reinforcing client confidence in product reliability. Strong logistical networks also play an essential role in the operational efficiency of Chinese flange manufacturers. With advanced supply chain management and strategic partnerships with key logistics providers, they ensure timely delivery of products worldwide. This capability is crucial in maintaining project schedules and minimising downtime, factors that significantly impact project costs and customer satisfaction. Before forging partnerships with flange manufacturers in China, interested parties should conduct detailed due diligence. This can involve requesting technical specifications, quality assurance certifications, client references, and facility audits. Through careful evaluation, businesses can secure partnerships that guarantee high-quality flange solutions, ultimately boosting their competitiveness in global markets. In conclusion, Chinese flange manufacturers are making significant strides in the global marketplace by blending traditional craftsmanship with cutting-edge technology. By prioritizing quality, customization, and customer satisfaction, these manufacturers not only uphold high standards but also build lasting relationships with clients worldwide.

Latest news

-

ANSI 150P SS304 SO FLANGE

NewsFeb.14,2025

-

ASTM A333GR6 STEEL PIPE

NewsJan.20,2025

-

ANSI B16.5 WELDING NECK FLANGE

NewsJan.15,2026

-

ANSI B16.5 SLIP-ON FLANGE

NewsApr.19,2024

-

SABS 1123 FLANGE

NewsJan.15,2025

-

DIN86044 PLATE FLANGE

NewsApr.19,2024

-

DIN2527 BLIND FLANGE

NewsApr.12,2024

-

JIS B2311 Butt-Welding Fittings LR/SR 45°/90° /180°Seamless/Weld

NewsApr.23,2024