-

Cangzhou Yulong Steel Co., Ltd.

-

Phone:

+86 13303177267 -

Email:

admin@ylsteelfittings.com

- English

- Arabic

- Italian

- Spanish

- Portuguese

- German

- kazakh

- Persian

- Greek

- French

- Russian

- Polish

- Thai

- Indonesian

- Vietnamese

- Zulu

- Korean

- Uzbek

- Hindi

- Serbian

- Malay

- Ukrainian

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Miao

- Hungarian

- Icelandic

- igbo

- irish

- Japanese

- Javanese

- Kannada

- Khmer

- Rwandese

- Afrikaans

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Esperanto

- Estonian

- Finnish

- Frisian

- Galician

- Georgian

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Dutch

- Punjabi

- Romanian

- Samoan

- Scottish Gaelic

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Turkish

- Turkmen

- Urdu

- Uighur

- Welsh

- Bantu

- Yiddish

- Yoruba

Jan . 28, 2025 00:46 Back to list

high pressure pipe welding

High pressure pipe welding stands as a critical process across numerous industries, demanding not only specialized skills but also robust equipment and knowledgeable oversight. The key to understanding high pressure pipe welding lies in dissecting its core elements the tools, techniques, and expertise required to safely join pipes intended to transport fluids or gases under high pressures.

Authoritativeness in high pressure pipe welding is significantly reliant on adherence to stringent industry standards and codes. Noteworthy organizations such as the American Society of Mechanical Engineers (ASME) and the American Petroleum Institute (API) set the benchmarks for safety and quality in welding practices. Compliance with these standards is not merely a recommendation but a mandatory requirement to ensure safety and reliability. Trustworthiness, on the other hand, comes from a company's reputation and history of successful project delivery. Trust is built over time, with companies that invest in continuous training and quality assurance typically garnering more credibility. Usage of advanced technologies, such as automated welding and non-destructive testing methods like radiographic or ultrasonic testing, further elevates a company’s reliability. These technologies help in accurately assessing the integrity of welds without compromising the system, maintaining safety standards throughout the pipeline's operational lifespan. The complexity of high pressure pipe welding should not be underestimated. It is a field that brings together material science, engineering precision, and skilled craftsmanship. Companies and professionals who excel in this domain do so through an unwavering commitment to safety, a dedication to skill enhancement, and a robust foundation of technical knowledge. By maintaining focus on these principles and upholding the highest standards, the integrity and safety of high pressure systems are ensured, safeguarding not only the infrastructure but also the environments and communities surrounding them.

Authoritativeness in high pressure pipe welding is significantly reliant on adherence to stringent industry standards and codes. Noteworthy organizations such as the American Society of Mechanical Engineers (ASME) and the American Petroleum Institute (API) set the benchmarks for safety and quality in welding practices. Compliance with these standards is not merely a recommendation but a mandatory requirement to ensure safety and reliability. Trustworthiness, on the other hand, comes from a company's reputation and history of successful project delivery. Trust is built over time, with companies that invest in continuous training and quality assurance typically garnering more credibility. Usage of advanced technologies, such as automated welding and non-destructive testing methods like radiographic or ultrasonic testing, further elevates a company’s reliability. These technologies help in accurately assessing the integrity of welds without compromising the system, maintaining safety standards throughout the pipeline's operational lifespan. The complexity of high pressure pipe welding should not be underestimated. It is a field that brings together material science, engineering precision, and skilled craftsmanship. Companies and professionals who excel in this domain do so through an unwavering commitment to safety, a dedication to skill enhancement, and a robust foundation of technical knowledge. By maintaining focus on these principles and upholding the highest standards, the integrity and safety of high pressure systems are ensured, safeguarding not only the infrastructure but also the environments and communities surrounding them.

Next:

Latest news

-

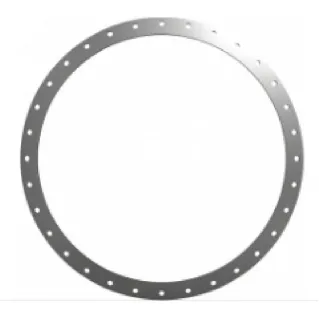

ANSI 150P SS304 SO FLANGE

NewsFeb.14,2025

-

ASTM A333GR6 STEEL PIPE

NewsJan.20,2025

-

ANSI B16.5 WELDING NECK FLANGE

NewsJan.15,2026

-

ANSI B16.5 SLIP-ON FLANGE

NewsApr.19,2024

-

SABS 1123 FLANGE

NewsJan.15,2025

-

DIN86044 PLATE FLANGE

NewsApr.19,2024

-

DIN2527 BLIND FLANGE

NewsApr.12,2024

-

JIS B2311 Butt-Welding Fittings LR/SR 45°/90° /180°Seamless/Weld

NewsApr.23,2024