-

Kubahiriza bisanzwe:

ANSI / ASME B16.9 ingofero yo gusudira yubahiriza ibisobanuro byagaragajwe n'ikigo cy’igihugu gishinzwe ubuziranenge muri Amerika (ANSI) hamwe n’umuryango w’abanyamerika bashinzwe imashini (ASME). Ibipimo ngenderwaho byemeza uburinganire, guhuza, no kwizerwa mugushushanya no gukora, byorohereza kwishyira hamwe muburyo bwa sisitemu.

-

Guhuza Butt-Welding:

Ibifuniko byo gusudira byashyizweho mugusudira neza kugeza kumpera yumuyoboro, bigakora ihuza rihoraho kandi rikomeye. Tekinike yo gusudira ikubiyemo gushyushya impera z'umuyoboro na capa kugeza aho bishonga, hanyuma ukabikanda hamwe kugirango ube umurunga wa metallurgji. Ubu buryo bwo gusudira butanga imbaraga zikomeye kandi zidashobora kumeneka, bikuraho ibikenerwa byongeweho kashe.

-

Gufunga Ikidodo:

Igikorwa cyibanze cya butt-welding caps nugutanga gufunga gufunga kurangiza imiyoboro muri sisitemu yo kuvoma. Iyi capa iranga ubuso bunini cyangwa buringaniye butwikiriye imiyoboro, birinda kwinjira cyangwa egress ya flux cyangwa gaze. Guhuza gusudira byerekana kashe ikomeye, bigabanya ibyago byo kumeneka no gukomeza ubusugire bwa sisitemu.

-

Guhitamo Ibikoresho:

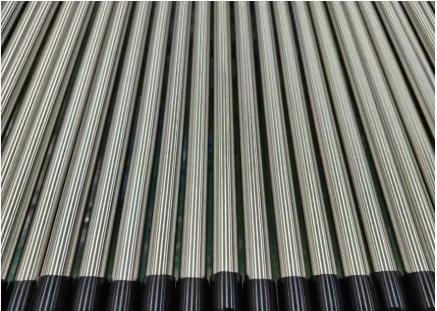

Utubuto two gusudira turaboneka mubikoresho bitandukanye kugirango bikore hamwe nibikorwa bitandukanye. Ibikoresho bisanzwe birimo ibyuma bya karubone, ibyuma bitagira umwanda, ibyuma bivanze, hamwe nudusimba twa ferrous nkumuringa cyangwa umuringa. Guhitamo ibikoresho biterwa nubushyuhe, umuvuduko, kurwanya ruswa, no guhuza amazi atwarwa.

-

Porogaramu zitandukanye:

ANSI / ASME B16.9 ingofero yo gusudira isanga ikoreshwa mubikorwa bitandukanye, birimo peteroli na gaze, peteroli, gutunganya imiti, gutunganya amazi, no kubyaza ingufu amashanyarazi. Zikoreshwa mu gufunga impera z'imiyoboro, amato, ibigega, n'ibikoresho, bitanga uburinzi bwo kwanduza, kwangirika, no kwangiza ibidukikije.

-

Amahitamo yihariye:

Mugihe butt-welding caps yubahiriza ibipimo bisanzwe nibisobanuro, amahitamo yihariye arahari kugirango yuzuze ibisabwa byumushinga. Ibi birashobora kubamo itandukaniro mubunini bwa cap, ubunini, urwego rwibintu, hamwe nubuso burangije. Ingofero yihariye irashobora guhuzwa kugirango ibe ihuza imiyoboro idasanzwe kandi ihuze ibihe bidasanzwe cyangwa ibidukikije bikora.

Buttweld Fittings Manufacturing Process

The manufacturing of buttweld fittings primarily involves two methods: cold drawing and hot forming.

The general steps in the process are as follows:

1. Material Preparation

The initial stage involves sourcing and preparing the raw materials needed for production.

2. Cutting

Pipes or plates are cut into specified shapes or lengths as per requirements.

3. Forming

The materials are shaped into various configurations, such as buttweld pipe caps, 90-degree elbows, and reducing tees. Cold drawn products are formed directly into their designated shapes using hammers, mechanical presses, or upsetters. In contrast, the hot forming process begins with heating the material, followed by shaping it.

4. Heat Treatment

This process entails heating and cooling the metals to alter their microstructure, enhancing both physical and mechanical properties to achieve the desired characteristics.

5. Machining

Sharp cutting tools are employed in this stage to refine shapes and prepare the ends of the fittings.

6. Inspection and Testing

The products undergo a thorough inspection in accordance with relevant standards, checking dimensions, material quality, and appearance.

7. Coating (if required)

Finally, a coating may be applied as necessary to meet specific requirements.

Butt Weld Pipe Cap FAQs

-

What materials are the butt weld pipe caps made from?

- Our butt weld pipe caps are crafted from high-quality materials including carbon steel, stainless steel, and alloy steel. This selection ensures durability and resistance to corrosion, making them suitable for a wide range of applications in various industries such as oil and gas, water supply, and construction.

-

What sizes are available for the butt weld pipe caps?

- We offer a comprehensive range of sizes for our butt weld pipe caps, from small diameters to large fittings, accommodating various pipe sizes. Please refer to the product listing for specific dimensions or contact our customer support for assistance in selecting the appropriate size for your project needs.

-

Are these butt-weld pipe caps suitable for high-pressure applications?

- Yes, our butt weld pipe caps are designed to support high-pressure applications. They meet industry standards and specifications, providing a secure and leak-proof seal that can withstand significant pressure levels. Be sure to check the specifications to ensure compatibility with your particular system requirements.

-

How do I install the butt weld pipe caps?

- Installing butt weld pipe caps requires welding them directly to the pipe for a strong, permanent connection. We recommend using qualified welders and following proper welding procedures to ensure a secure fit and maintain the integrity of the piping system. For detailed installation guidelines, please consult the accompanying technical documentation.

-

Can these butt-weld pipe caps be used in outdoor applications?

Absolutely! Our butt weld pipe caps are suitable for both indoor and outdoor applications. They are built to withstand environmental factors, making them ideal for exterior installations. For prolonged exposure to harsh conditions, we recommend our stainless steel options for enhanced resistance to corrosion.

ANSI / ASME B16.9 imipira yo gusudira ningingo zingirakamaro muri sisitemu yo gutunganya inganda, itanga gufunga umutekano kandi udashobora kumeneka kumpera. Kuba bubahiriza ibipimo bya ANSI na ASME, guhuza butt-gusudira, ubushobozi bwo gufunga, hamwe nuburyo butandukanye bituma babisabwa mubikorwa bitandukanye mubikorwa bitandukanye. Hamwe na capit-gusudira, injeniyeri nabakoresha barashobora kwemeza ubunyangamugayo, umutekano, nuburyo bwiza bwa sisitemu zabo, bigira uruhare mubikorwa byoroshye kandi bitarimo ibibazo.