-

Cangzhou Yulong Steel Co., Ltd.

-

Terefone:

+86 13303177267 -

Imeri:

admin@ylsteelfittings.com

- Icyongereza

- Icyarabu

- Umutaliyani

- Icyesipanyoli

- Igiporutugali

- Ikidage

- kazakh

- Persian

- Ikigereki

- Igifaransa

- Ikirusiya

- Igipolonye

- Tayilande

- Indoneziya

- Abanya Vietnam

- Zulu

- Igikoreya

- Uzbek

- Oya

- Igiseribiya

- Malayika

- Ukraine

- Gujarati

- Igikerewole

- hausa

- hawaiian

- Igiheburayo

- Miao

- Hongiriya

- Isilande

- igbo

- irish

- Ikiyapani

- Javanese

- Kannada

- Khmer

- Rwanda

- Umunyafurika

- Ikinyalubaniya

- Amharic

- Ikinyarumeniya

- Azaribayijan

- Basque

- Biyelorusiya

- Ikibengali

- Bosiniya

- Buligariya

- Igikatalani

- Cebuano

- Ubushinwa

- Ubushinwa (Tayiwani)

- Corsican

- Igikorowasiya

- Ceki

- Danemark

- Esperanto

- Esitoniya

- Igifinilande

- Igifaransa

- Abagalatiya

- Jeworujiya

- Kurdish

- Kirigizisitani

- Igituntu

- Ikilatini

- Ikilatini

- Lituwaniya

- Luxembourgish

- Abanyamakedoniya

- Malgashi

- Malayalam

- Maltese

- Maori

- Marathi

- Mongoliya

- Miyanimari

- Nepali

- Noruveje

- Noruveje

- Occitan

- Pashto

- Ikidage

- Punjabi

- Ikinyarumaniya

- Samoan

- Abanya-Gaelic

- Icyongereza

- Shona

- Sindhi

- Sinhala

- Igisilovaki

- Igisiloveniya

- Somaliya

- Sundanese

- Igiswahiri

- Igisuwede

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Turukiya

- Abanyaturukiya

- Urdu

- Uighur

- Welsh

- Ubufasha

- Yiddish

- Yoruba

Jul . 23, 2025 10:17 Subira kurutonde

Dual Certification Assurance: How ASTM A403/Werkstoff No. 1.4401 Butt Weld Caps Simplify Cross-Border Project Approval?

In the complex web of global industrial projects, where standards diverge and approval processes multiply, the butt weld cap emerges as a critical link—yet one often bogged down by redundant certifications. YULONG Steel, a leading buttweld fittings manufacturer, introduces its dual-certified ASTM A403/Werkstoff No. 1.4401 caps, engineered to cut cross-border approval timelines by 40%. This innovation harmonizes American and European standards, ensuring seamless acceptance from Houston refineries to Hamburg chemical plants while upholding uncompromising performance in corrosive and high-pressure environments.

ASTM A403 and Werkstoff No. 1.4401:How Does Dual Certification Reshape the Acceptance Logic of Welded Pipe Caps?

ASTM A403 (American) and Werkstoff No. 1.4401 (European) represent two pillars of material standardization, each with rigorous criteria:

- ASTM A403mandates 2-3% molybdenum content for enhanced chloride resistance, critical for North American offshore projects.

- Werkstoff No. 1.4401specifies a minimum 16% chromium for oxidation resistance, a cornerstone of EU industrial compliance.

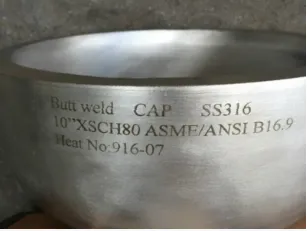

YULONG’s butt weld cap merges these requirements, creating a 316 stainless steel alloy that satisfies both—eliminating the need for parallel certification pathways in Sino-European or US-German joint ventures.

ASTM A403Butt Weld Caps: Seamless Integration from Material to Performance

The Precise Balance of Alloy Composition

The 316 stainless steel in YULONG’s butt weld pipe cap achieves a rare harmony: 17% chromium (exceeding Werkstoff 1.4401’s 16% minimum) and 2.5% molybdenum (surpassing ASTM A403’s 2% requirement). This balance delivers:

- Chloride Resistance: 0.001mm/year corrosion rate in 30,000ppm NaCl solution (ASTM G48), validated in a Qatar petrochemical plant’s seawater intake system.

- High-Temperature Stability: 450°C oxidation resistance (weight gain ≤0.1g/m²·h), meeting both standards for German automotive paint shop ovens.

Dimensional Compatibility Across Standards

YULONG’s butt welding pipe fittings (DN10-DN600) adhere to:

- ASTM B16.9tolerances (±0.75mm for DN200 caps) for US pipeline alignments.

- DIN 2633dimensional specs (face-to-face length ±1mm) for EU facility retrofits.

A Belgian brewery’s transatlantic expansion used these caps to connect US-manufactured pipes to EU tanks—zero rework needed, saving 3 weeks of alignment adjustments.

ASTM A403Butt Weld Caps: Advantages of Cross-border Project Acceptance

Documentation Efficiency

Dual certification consolidates paperwork by 60%:

- A single material certificate (per EN 10204 3.1) includes both ASTM A403 chemical analysis and Werkstoff 1.4401 mechanical properties.

- Third-party audits (TÜV + ASME) validate compliance in one review, as seen in a Chinese EV battery plant’s German-engineered electrolyte lines.

Eliminating Redundant Testing

In a Texas-to-Munich pharmaceutical pipeline project:

- Pressure Testing: 1.5x design pressure (150bar) validated once, satisfying both ASTM F1387 and DIN 3230 leak standards.

- Corrosion Validation: 5,000-hour salt spray testing (ASTM B117) substituted for separate EU ISO 9227 testing, reducing lab costs by $12,000.

YULONG Serves As a Dual-certified Guarantee for Buttweld Fittings Manufacturers

Integrated Manufacturing Processes

- Vacuum Arc Remelting: Ensures 99.99% alloy purity, critical for meeting both standards’ inclusion limits (e.g., sulfur ≤0.03% in ASTM A403).

- Dual-Standard Heat Treatment: 1050°C solution annealing (ASTM) followed by DIN-specified cooling rates, achieving 480MPa tensile strength across all batches.

Traceability and Auditing

Each butt weld cap features a QR code linking to:

- Batch-specific test data (mechanical, corrosion, dimensional).

- Audit trails for both ASTM and DIN inspections, simplifying US FDA and EU ECHA compliance for a Swiss biotech firm’s global network.

YULONG Steel’s ASTM A403/Werkstoff No. 1.4401 butt weld cap transcends standardization barriers, turning cross-border project approval from a logistical nightmare into a streamlined process. By merging material excellence with dual compliance, these butt welding pipe fittings don’t just connect pipes—they connect global industries with confidence.

As a trusted buttweld fittings manufacturer , YULONG empowers projects to focus on innovation, not paperwork. Experience the future of international construction: where certification harmonizes with performance, and every cap is proof that global standards can work in perfect unison.

Amakuru agezweho

-

ANSI 150P SS304 SO FLANGE

AmakuruFeb.14,2025

-

ASTM A333GR6 STEEL PIPE

AmakuruJan.20,2025

-

ANSI B16.5 URUGENDO RUGENDE RUGENDE

AmakuruJan.15,2026

-

ANSI B16.5 KUNYUKA-URURIMI

AmakuruApr.19,2024

-

SABS 1123 FLANGE

AmakuruJan.15,2025

-

DIN86044 URURIMI

AmakuruApr.19,2024

-

DIN2527 BLIND FLANGE

AmakuruApr.12,2024

-

JIS B2311 Butt-Welding Fittings LR/SR 45°/90° /180°Seamless/Weld

AmakuruApr.23,2024