-

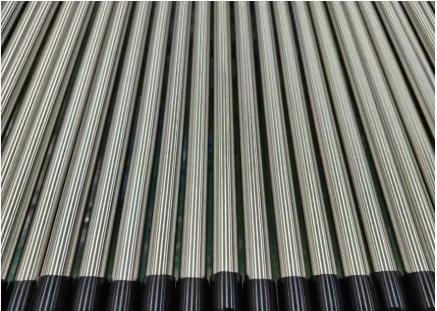

Ubwubatsi Bwuzuye: Imiyoboro y'icyuma ikozwe hifashishijwe tekinoroji yubuhanga igezweho kugirango harebwe ibipimo nyabyo, imirongo igororotse, nibiranga imigendekere myiza. Yaba 3D, 5D, 6D, cyangwa 8D yunamye, buri kimwe cyakozwe muburyo bwitondewe kugirango cyuzuze ubuziranenge bwo hejuru nibisobanuro byinganda.

-

Amazi meza meza: Kugabanuka neza kwicyuma cyicyuma kigabanya imivurungano nigabanuka ryumuvuduko, bigatuma amazi atembera neza muri sisitemu yo kuvoma. Igishushanyo mbonera cyongera imikorere muri sisitemu mugihe kigabanya gukoresha ingufu nigiciro cyibikorwa.

-

Porogaramu zitandukanye: Imiyoboro y'ibyuma isanga ikoreshwa cyane mu nganda zitandukanye, zirimo peteroli na gaze, peteroli, amashanyarazi, amashanyarazi, gutunganya amazi, n'ibindi. Byaba bikoreshwa muguhuza imiyoboro, guhindura icyerekezo cyerekezo, cyangwa gutezimbere inzira, iyi yunamye itanga ibisubizo bitandukanye kubibazo bitoroshye.

-

Ubwubatsi burambye: Yubatswe mubikoresho byujuje ubuziranenge nk'icyuma cya karubone, ibyuma bitagira umwanda, cyangwa ibyuma bivanze, ibyuma bya Steel Pipe Bend byerekana imbaraga zidasanzwe kandi biramba. Bahinguwe kugirango bahangane nibidukikije byangirika, ubushyuhe bwinshi, numuvuduko mwinshi, byemeza imikorere yigihe kirekire kandi yizewe.

-

Bend Radii zitandukanye: Imiyoboro y'icyuma iraboneka muri radiyo itandukanye, harimo 3D, 5D, 6D, na 8D, kugirango ihuze ibyifuzo byihariye hamwe n'imbogamizi z'umwanya. Radiyo yunamye yerekana ubugororangingo bugoramye ugereranije na diameter ya pipe ya nominal, itanga ihinduka mugushushanya no kuyishyiraho.

-

Kwishyira hamwe: Umuyoboro w'icyuma Wunamye winjiza muri sisitemu ihari, itanga uburyo bworoshye bwo kuyitunganya no kuyitunganya. Ibipimo byabo bisanzwe hamwe nubuhanga busobanutse neza byemeza guhuza nibindi bikoresho bigize imiyoboro, kugabanya igihe cyateganijwe no kunoza imikorere ya sisitemu.

Ibintu by'ingenzi:

- Ubwubatsi bwuzuye kubwamazi meza

- Porogaramu zinyuranye mu nganda

- Ubwubatsi burambye kubwigihe kirekire

- Amahitamo atandukanye ya radii (3D, 5D, 6D, 8D)

- Kwishyira hamwe muri sisitemu ihari

- Igisubizo kiboneye cyo kuyobora imiyoboro no guhindura icyerekezo

Applications of Steel Tube Bends

The applications of steel tube bends are vast and varied. They are primarily used in industries such as:

1. Construction: Steel tube bends are integral to constructing buildings, bridges, and other infrastructures. They provide essential support and stability, allowing for more creative architectural designs.

2. Automotive: In automotive manufacturing, these bends are used in exhaust systems and frame support, ensuring vehicles can withstand dynamic stresses while maintaining proper airflow.

3. Pipelines: Within pipeline systems, steel tube bends facilitate transport across uneven terrains, enabling fluid movement without excessive pressure loss.

4. Manufacturing Equipment: Many industrial machines utilize steel tube bends in their design for optimal functionality and efficient operation.

5. Furniture Design: The aesthetic appeal of curved steel in furniture design has become increasingly popular, providing both strength and style.

Advantages of Steel Tube Bends

A47Strength and Durability: Steel is renowned for its strength, making it an ideal choice for applications that require load-bearing capabilities. Steel tube bends are less likely to dent or deform under pressure.

Versatility: Available in various configurations, steel tube bends can be customized to fit any project specification, providing design flexibility.

Corrosion Resistance: Stainless steel tube bends offer excellent resistance to oxidation and corrosion, making them suitable for outdoor and industrial applications.

Cost-Effective**: Despite the initial investment, the longevity and low maintenance requirement of steel tube bends make them a cost-effective option over time.