-

Cangzhou Yulong Steel Co., Ltd.

-

Phone:

+86 13303177267 -

Email:

admin@ylsteelfittings.com

- English

- Arabic

- Italian

- Spanish

- Portuguese

- German

- kazakh

- Persian

- Greek

- French

- Russian

- Polish

- Thai

- Indonesian

- Vietnamese

- Zulu

- Korean

- Uzbek

- Hindi

- Serbian

- Malay

- Ukrainian

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Miao

- Hungarian

- Icelandic

- igbo

- irish

- Japanese

- Javanese

- Kannada

- Khmer

- Rwandese

- Afrikaans

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Esperanto

- Estonian

- Finnish

- Frisian

- Galician

- Georgian

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Dutch

- Punjabi

- Romanian

- Samoan

- Scottish Gaelic

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Turkish

- Turkmen

- Urdu

- Uighur

- Welsh

- Bantu

- Yiddish

- Yoruba

júl . 24, 2025 01:01 Back to list

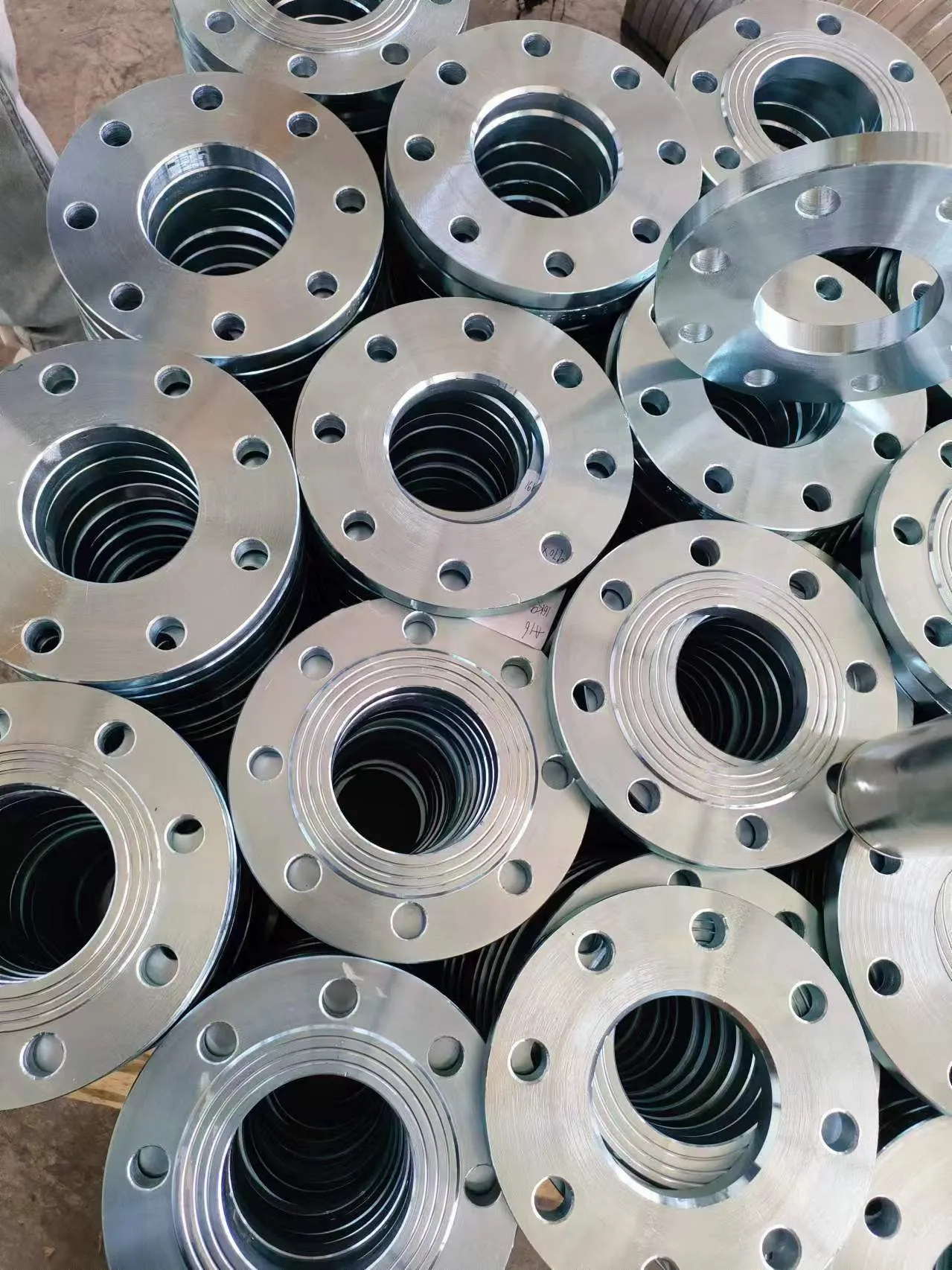

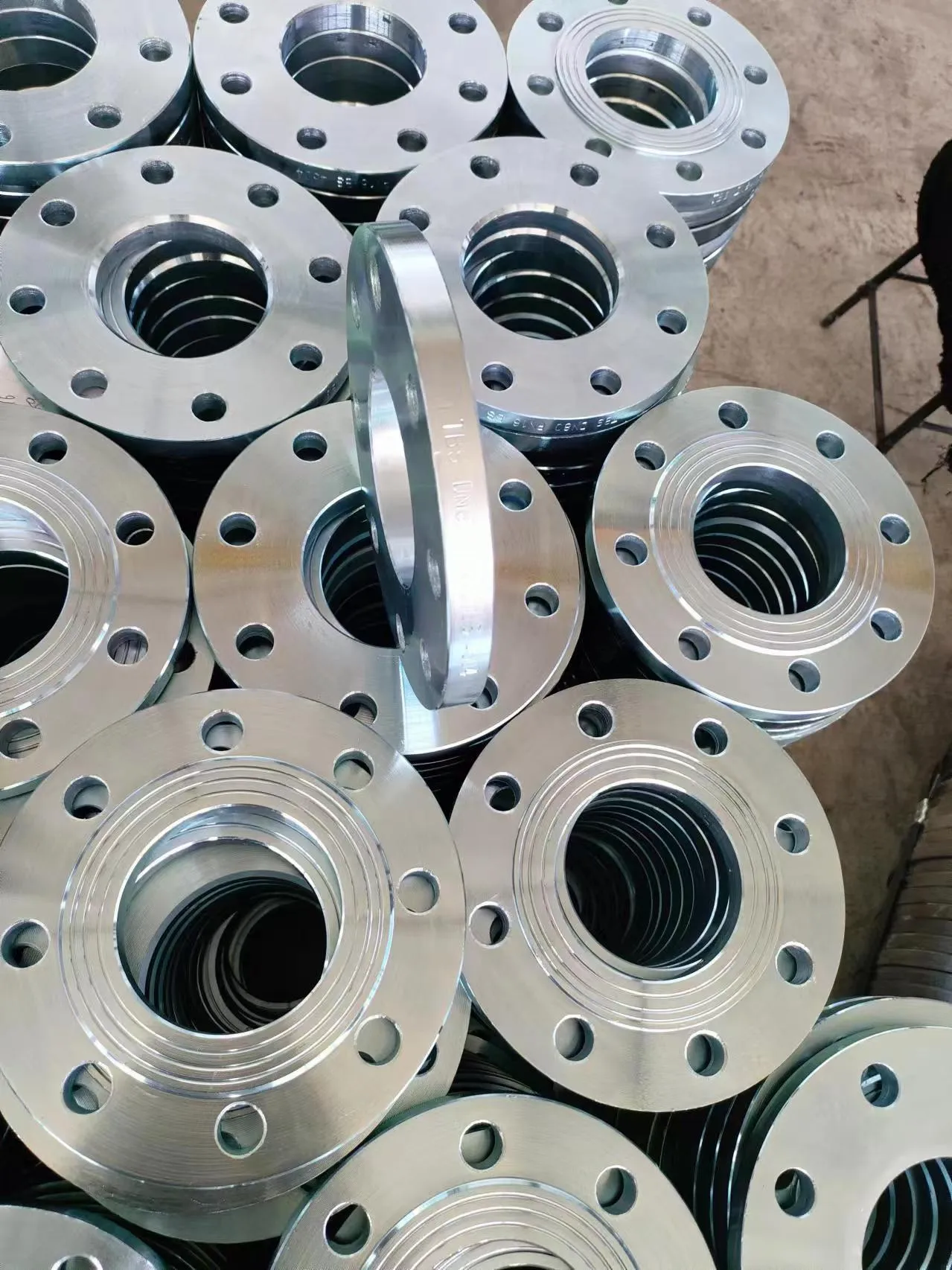

Flange BS4504 Wholesale Supplier - High Quality Steel Flanges

Official Website

- Phone: +86 13303177267

- Email: admin@ylsteelfittings.com

- Mobile: +86 13303177267

- Address: Lijiapu,Wulongtang Village,Cang County,Cangzhou City, Hebei Province

1. Introduction: The Industry Relevance of Flange BS4504

In modern industrial piping systems, the flange bs4504 has emerged as a critical standard for safe, durable, and reliable pipeline connection solutions, particularly for applications in Europe and regions adhering to British Standards. As industries demand increased performance — such as greater corrosion resistance, adaptability to various pressure classes, and enhanced conductivity — advanced products like the BS4504 ELECTRICAL/COLD GALVANIZED PLATE FLANGE from CANGZHOU YULONG STEEL CO.,LTD. are leading the way.

This comprehensive guide explores the evolving landscape around flange bs4504, offering technical details, data visualizations, application insights, and expert answers to help engineers, procurement specialists, and project managers navigate choices, standards, and innovation in flange technology.

2. Industry Trends and Innovation around Flange BS4504

The flange bs4504 standard has seen increasing relevance in electrification projects, chemical pipelines, and building infrastructure thanks to its harmonization with global engineering practices and compatibility with ISO standards (Source). Recent research and market data suggest several key trends:

- Higher Corrosion Resistance: Cold and electro-galvanizing surface treatments are prioritized in critical infrastructure, resulting in extended component lifecycles and reduced maintenance frequency (see Journal of Materials Processing Technology: link).

- Standardization Drives Interchangeability: Flange bs4504 streamlines cross-brand compatibility, simplifying procurement and logistics.

- Rising Demand in Specialized Electrical & Anti-Static Environments: The technical advantages of electrical/cold galvanized flanges address emerging needs in energy, chemicals, and electronics manufacturing.

- Digital Selection & Engineering: Designer reliance on datasheets, parametric 2D/3D models, and industry data is accelerating, underscoring the need for clear, reliable product information and technical visualization.

3. What is Flange BS4504? Standard Scope and Key Features

The British Standard BS4504 defines the dimensional, material, and test requirements for circular steel flanges for pipes, valves, and fittings. Flange bs4504 fittings are extensively used in pipelines carrying water, oil, gas, or chemicals, serving pressures up to PN40 (40 bar). Key features include:

- Compatibility: Harmonized with ISO 7005, widely interchangeable.

- Pressure Ratings: PN6, PN10, PN16, PN25, PN40 (6–40 bar).

- Materials: Carbon steel, stainless steel, specialty alloys, galvanized finishes for enhanced properties.

- Types: Plate, slip-on, weld neck, blind, threaded, socket welded.

- Applications: Power generation, chemical process, marine, waterworks, and electrical systems.

- Surface Treatments: Cold/electro-galvanized, painted, or raw, adapted to specific corrosivity classes.

4. Flange BS4504 Technical Parameters: Comparison Table

| Parameter | Description | BS4504 Typical Range |

|---|---|---|

| Nominal Pipe Size (DN) | Bore diameter reference (mm) | 15–2000 mm |

| Pressure Class (PN) | Maximum allowable pressure (bar) | PN6, PN10, PN16, PN25, PN40 |

| Flange Thickness (C) | Plate thickness (mm) | 12–58 mm |

| Bolt Circle Diameter (K) | Center-to-center diameter (mm) | 65–2220 mm |

| Number of Bolt Holes (n) | Total per flange | 4–72 |

| Surface Finish | Galvanized, Painted, Raw | Electrogalvanized, Cold Galvanized |

| Material Grades | Steel & Alloy Types | Carbon Steel, Stainless (304, 316, etc.), Alloy Steels |

5. Data Visualization: Flange BS4504 Industry Metrics & Product Parameters

6. Application Scenarios for Flange BS4504

The robust technical and protective specifications of flange bs4504 make it a prime choice for a broad array of applications:

- Electrical Equipment & Antistatic Piping: The enhanced conductivity of the BS4504 ELECTRICAL/COLD GALVANIZED PLATE FLANGE makes it suitable for sensitive installations where electrical connection continuity and grounding are relevant.

- Oil & Gas: Used in gathering lines, transmission pipelines, and equipment that must withstand both internal pressure and severe external environments.

- Waterworks & Power Generation: Reliable long-term performance in power stations, pumping facilities, and plant utilities.

- Chemical & Petrochemical: High resistance to chemical attack is essential; even atmospheres with strong corrosives (acids, bases) can be countered with proper flange selection.

- Heating, Ventilation, and Sanitary Installations: Ensures leak-free, standardized connections for both new builds and maintenance projects.

- Marine Engineering: Corrosion-optimized flanges are vital for seawater exposure, with galvanized finishes providing redundancy to barrier coatings.

7. BS4504 ELECTRICAL/COLD GALVANIZED PLATE FLANGE: Core Specs & Performance

| Specification | BS4504 ELECTRICAL/COLD GALVANIZED | General BS4504 Plate Flange |

|---|---|---|

| Standard | BS4504, ISO 7005 | BS4504, ISO 7005 |

| Surface Finish | Electrical/Cold Galvanized (Uniform Coating) | Painted or Raw Steel |

| Nominal Sizes | DN15–DN2000 | DN15–DN2000 |

| Pressure Classes | PN6–PN40 | PN6–PN40 |

| Electrical Conductivity | High (Suitable for electrical connections & antistatic use) | Low/Standard |

| Corrosion Resistance | Superior (Zn coating thickness 20–45 μm) | Standard |

| Lifecycle (Avg. Years) | 15–22 | 8–13 |

| Applications | Electrical, Antistatic, Chemical, Marine, Power | Civil/General Industry |

8. Professional FAQ on Flange BS4504

9. Authority Citations & Trust-Building References

- Materials Processing Tech Journal: Surface analysis of electro-galvanized steel plate

- Engineering Toolbox - Flange Standards Info: https://www.engineeringtoolbox.com/flanges-d_1150.html

- ResearchGate - Flange Connections and Sealing: Study on Flange Connections

- Pipefitting Forum - User Experiences of flange bs4504: https://www.eng-tips.com/viewthread.cfm?qid=440733

- CANGZHOU YULONG STEEL CO.,LTD. Product Info: BS4504 Electrical/Cold Galvanized Plate Flange

Key sources: Journal of Materials Processing Technology, Eng-Tips Forum, and Engineering Toolbox.

Latest news

-

ANSI 150P SS304 SO FLANGE

NewsFeb.14,2025

-

ASTM A333GR6 STEEL PIPE

NewsJan.20,2025

-

ANSI B16.5 WELDING NECK FLANGE

NewsJan.15,2026

-

ANSI B16.5 SLIP-ON FLANGE

NewsApr.19,2024

-

SABS 1123 FLANGE

NewsJan.15,2025

-

DIN86044 PLATE FLANGE

NewsApr.19,2024

-

DIN2527 BLIND FLANGE

NewsApr.12,2024

-

JIS B2311 Butt-Welding Fittings LR/SR 45°/90° /180°Seamless/Weld

NewsApr.23,2024