Flange PN10 EN1092-1 Type01 is a common flange specification. The following is a brief description of the standard, pressure level, type, etc.:

Tloaelo: EN1092-1 is a European standard that specifies the dimensions, tolerances, pressure-temperature ratings, materials, etc. of pipe flanges and flanged pipe fittings. Flanges that meet this standard are widely used in Europe and many regions and industries that adopt European standards, ensuring the interchangeability and compatibility of flanges in different equipment and piping systems.

Pressure level: PN10 means that the nominal pressure of the flange is 10bar. The nominal pressure refers to the standard pressure value that the flange can withstand within a certain temperature range, which reflects the pressure bearing capacity of the flange under normal working conditions. PN10 flanges are suitable for some relatively low-pressure piping systems, such as general water supply and drainage, HVAC and other systems.

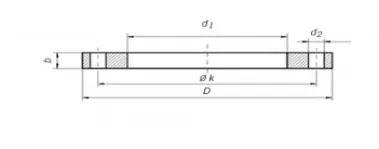

Type: Type01 refers to the specific structural type of the flange. In the EN1092-1 standard, different types correspond to different flange structures and size parameters. Type01 usually represents a specific plate-type flat-weld flange. This flange generally has a simpler structure, consisting of a flat flange and a short neck, and is connected to the pipeline by welding. Its advantages are relatively simple manufacturing process, low cost, and convenient installation and disassembly.

Kopo: This flange is usually used to connect various pipeline systems, such as pipelines with a pressure level of PN10 in industries such as chemical, petroleum, natural gas, and water treatment. It can reliably connect pipelines to pipelines, pipelines to equipment (such as pumps, valves, etc.), and ensure the sealing and stability of the pipeline system.