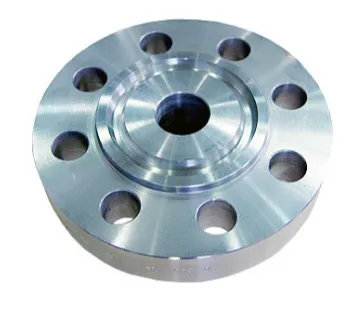

RTJ Flange is a ring joint flange. Here is its introduction:

Likarolo tsa sebopeho

Sealing surface form: RTJ (Ring Type Joint) means that it adopts a ring joint surface sealing form. This sealing surface consists of two matching annular grooves and a metal ring gasket. The annular groove is usually processed on the sealing surface of the flange, and the shape is trapezoidal or octagonal. The metal ring gasket is placed between the annular grooves of the two flanges. The ring gasket is plastically deformed by tightening the bolts to achieve sealing.

Connection method: Generally, bolts are used to fix two pipes or equipment to be connected. There are evenly distributed bolt holes on the flange. Bolts and nuts are used to tightly connect the two flanges together to ensure the sealing and stability of the pipeline system.

Material selection

Flange material: Common ones are carbon steel, stainless steel, alloy steel, etc. Carbon steel material has low cost, certain strength and corrosion resistance, and is suitable for general industrial environments; stainless steel material has better corrosion resistance and oxidation resistance, and is often used in occasions with high corrosion resistance requirements, such as chemical, food and beverage industries; alloy steel material can add different alloy elements according to specific needs to obtain higher strength, heat resistance or corrosion resistance and other special properties, suitable for high temperature, high pressure and other harsh working conditions.

Ring gasket material: usually made of metal materials, such as soft iron, copper, aluminum, stainless steel, etc. Different metal materials have different performance characteristics. Soft iron ring gaskets have good toughness and sealing, suitable for some occasions where the pressure is not too high; copper and aluminum ring gaskets have good thermal conductivity and corrosion resistance, suitable for pipelines with special media or temperature requirements; stainless steel ring gaskets have higher strength, corrosion resistance and high temperature resistance, suitable for high pressure, high temperature, and highly corrosive medium pipeline systems.

Application field

Indasteri ea peterole: In the process of petroleum refining, chemical production, etc., RTJ Flange is widely used in various high temperature, high pressure, flammable and explosive and corrosive medium pipeline systems. For example, in the connecting pipes of equipment such as oil cracking units, hydrogenation reactors, and high-pressure polyethylene units, RTJ Flange can ensure the safe operation of the pipeline system under harsh working conditions and prevent medium leakage.

Natural gas industry: RTJ Flange also has important applications in the extraction, transportation, and processing of natural gas. For example, in natural gas wellhead devices, pump stations, metering stations, and other places of long-distance pipelines, RTJ Flange is used to connect pipelines and equipment, which can withstand the high pressure during the natural gas transportation process, ensure the sealing of the pipeline system, and prevent natural gas leakage.

Indasteri ea matla: In the fields of power production such as thermal power generation and nuclear power generation, RTJ Flange is often used in important pipeline systems such as steam pipelines and main water supply pipelines. These pipelines are subjected to high temperatures and high pressures during operation.