Although SABS 1123 flanges have become obsolete in recent years, they can still be found if lightweight and economical stainless steel flanges are required. They are mainly used in applications that require hygiene and corrosion resistance. They are available in sizes from ½” to 48”, and they also have different pressure ratings. SABS 1123 flanges can be customized with surface treatments such as rust-proof paint or oil-black paint.

Customers can get SABS 1123 flanges in threaded, screw, forged, or plate form, and their production techniques include heat treatment, machining,g, and forging. These flanges can be used in asphalt upgrading units, heavy oil refineries, etc. Due to their corrosion resistance, they can also be used in the metallurgical and shipbuilding industries. These flanges are also available in different face types.

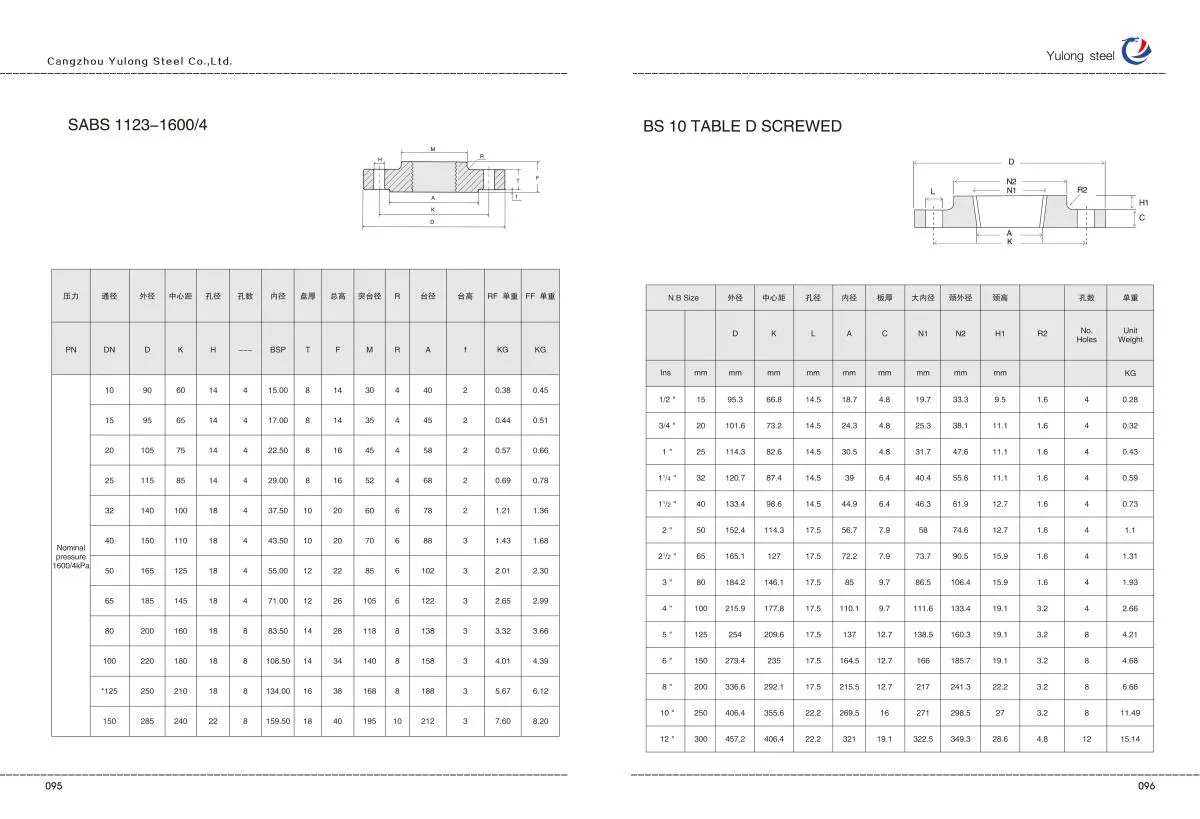

SABS 1123 Flange Dimensions

-

SABS 1123 Flange Dimensions

-

SABS 1123 Flange Specifications

What Are SABS 1123 Flanges

SABS 1123 flanges are a widely used standard in South Africa for piping systems in industries such as water treatment, oil & gas, and mining. These pipe flange types ensure a secure connection between industrial metal pipes, valves, and pumps, providing high durability and leak-proof performance.

At Yulong, we specialize in manufacturing premium SABS 1123 flanges that meet stringent industry standards. Our flanges are available in various pressure ratings (PN10, PN16, PN25, etc.), ensuring compatibility with different pipeline applications. Made from high-quality carbon steel, stainless steel, and galvanized materials, Yulong’s SABS 1123 flanges offer superior corrosion resistance and long-lasting durability, even in harsh environments.

Why Choose Yulong’s SABS 1123 Flanges?

Certified Quality – Our flanges comply with SABS 1123 and international standards, ensuring reliability and safety.

Precision Engineering – Manufactured with advanced machining techniques for a perfect fit and leak-proof sealing.

Wide Range of Options – Available in weld-neck, slip-on, blind, and socket-weld types to suit different applications.

Competitive Pricing & Fast Delivery – As a trusted global supplier, Yulong offers bulk orders at factory prices with efficient shipping.

Applications of SABS 1123 Flanges

Yulong’s SABS 1123 flanges are widely used in:

✔ Water & Wastewater Pipelines – Ensuring secure and corrosion-resistant connections.

✔ Oil & Gas Industry – High-pressure flanges for efficient fluid transmission.

✔ Mining & Industrial Systems – Withstanding extreme operational conditions.

Looking for reliable SABS flanges? Contact Yulong today for high-quality products at competitive prices. Upgrade your pipeline system with industry-leading flange solutions! 🚀

Up To What Temperature Sabs 1123 Pipe Flanges Are Used?

SABS 1123 pipe flanges are widely used in industrial piping systems across sectors such as water supply, petrochemicals, and power generation. A critical factor in their application is temperature resistance, which determines their durability and performance under extreme conditions.

Understanding SABS 1123 Temperature Limits

The temperature resistance of SABS 1123 flanges depends on their pressure rating (PN) and material composition. Standard pressure classes for these flanges include PN10, PN16, PN25, and PN40, each designed for specific operating environments. Generally, the temperature limit of these flanges aligns with the properties of the material used, such as carbon steel, stainless steel, or ductile iron.

Material and Its Impact on Temperature Resistance

Carbon Steel SABS 1123 Flanges

Typically withstand temperatures up to 400°C (752°F) in non-corrosive environments.

Suitable for general industrial and water systems.

Stainless Steel SABS 1123 Flanges

It offers superior temperature resistance, often up to 800°C (1472°F).

Ideal for high-temperature steam and chemical applications.

Ductile Iron SABS 1123 Flanges

Usually rated for temperatures up to 300°C (572°F).

Best for low-pressure applications such as water distribution.

Ensuring Optimal Performance

To maximize the lifespan of SABS 1123 flanges, it is essential to select the right material based on the temperature and pressure requirements of your system. Proper gasket selection and installation procedures also play a key role in maintaining a leak-free, high-temperature-resistant pipeline connection.

Looking for high-quality SABS 1123 flanges? Contact us today for expert recommendations and durable solutions tailored to your industrial needs! 🚀