Class F ring flanges are designed for use in water distribution systems with the highest pressure requirements compared to other classes of AWWA C207-18 flanges. These flanges are typically utilized in applications where the operating pressures are extremely high, such as in water treatment plants, wastewater facilities, and municipal water supply networks.

In AWWA C207-18, Class F ring flanges are classified based on their pressure rating and are constructed to ensure robustness and reliability in high-pressure waterworks applications. The standard specifies various dimensions for Class F flanges, including bolt circle diameter, number of bolt holes, bolt hole diameter, flange thickness, hub length, and facing dimensions.

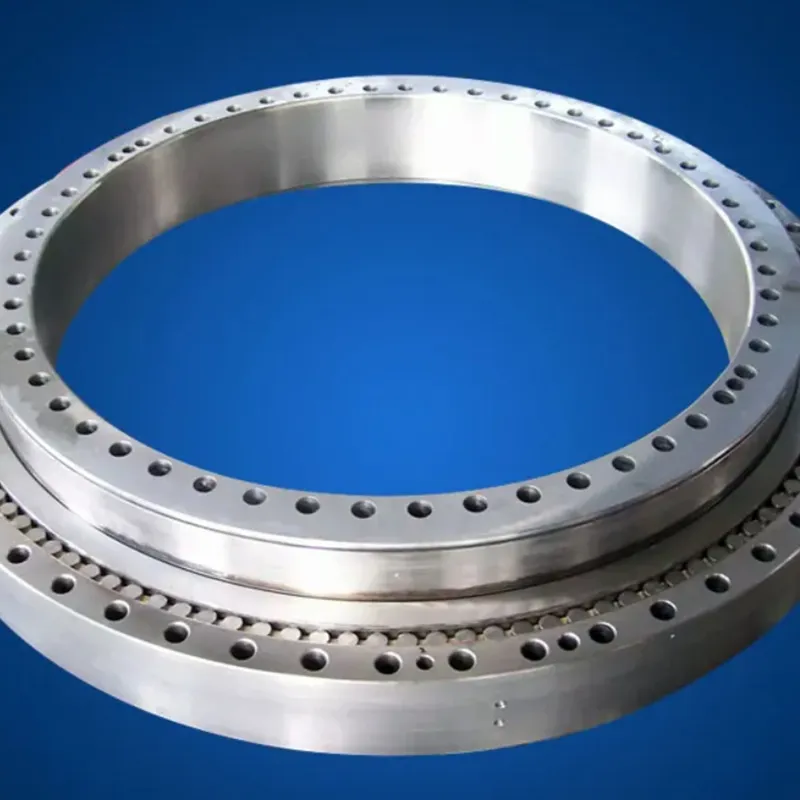

Class F ring flanges are typically made from high-quality materials like carbon steel or stainless steel to withstand the extreme pressures and potential corrosion in water distribution systems. The flanges are engineered to provide a secure and leak-free connection between pipes, valves, and fittings in high-pressure applications.

The specifications outlined in AWWA C207-18 for Class F ring flanges ensure compliance with the standards and guarantee proper alignment and sealing when installed in piping systems operating under high pressures.

In conclusion, Class F ring flanges as specified in AWWA C207-18 are essential components for water distribution systems requiring a strong and secure connection to withstand high-pressure environments in water treatment facilities, wastewater treatment plants, and municipal water supply networks.