Key Features:

- Secure sealing for water distribution systems

- Versatile options to meet different pressure and temperature requirements

- Durable construction to withstand water distribution environments

- Compliance with AWWA standards for quality and reliability

- Ease of installation with simple alignment and bolting

- Customization options available for specific project needs

-

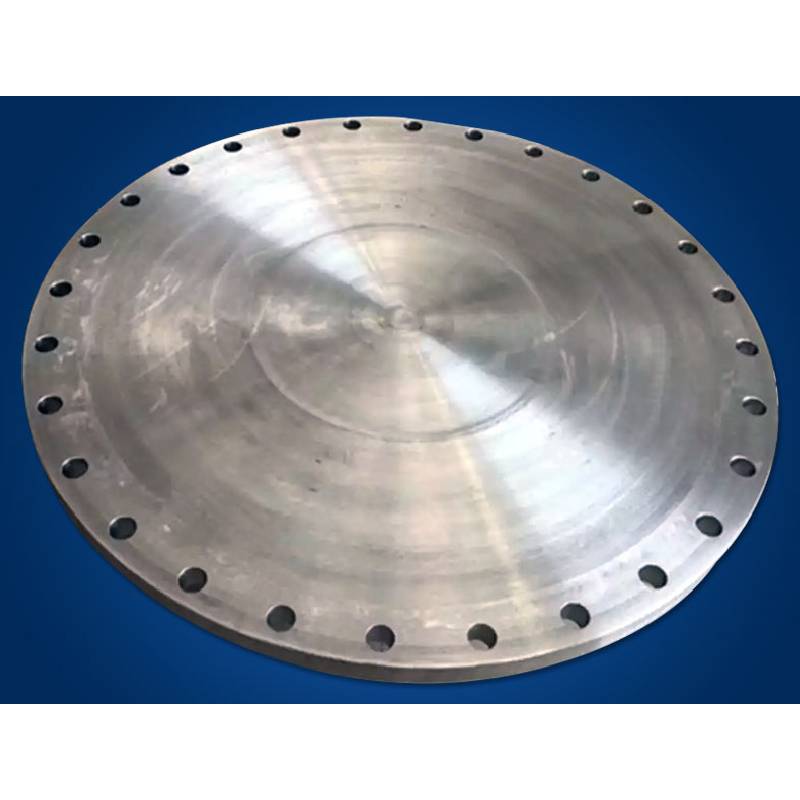

Secure Sealing: AWWA Class B, D, E, & F Blind Flanges feature a flat face design that ensures a tight seal when installed at the end of a pipe. This secure sealing capability prevents water leakage and maintains system integrity, minimizing the risk of contamination and ensuring the efficient delivery of clean water to consumers.

-

Versatile Options: Available in different classes, including Class B, D, E, and F, these blind flanges offer versatility to meet various pressure and temperature requirements in water distribution networks. Whether for potable water systems, irrigation projects, or wastewater treatment facilities, there is a suitable class of blind flange to accommodate specific application needs.

-

Durable Construction: Constructed from durable materials such as ductile iron, carbon steel, or stainless steel, AWWA Class B, D, E, & F Blind Flanges exhibit exceptional strength and durability. They are engineered to withstand the rigors of water distribution environments, including exposure to corrosion, abrasion, and fluctuating pressures.

-

Compliance with Standards: AWWA Class B, D, E, & F Blind Flanges adhere to the specifications outlined in the AWWA C207 standard, ensuring consistency in design, manufacturing, and performance. Compliance with industry standards and regulations provides assurance of quality and reliability, meeting the stringent requirements of water utility providers and regulatory authorities.

-

Ease of Installation: Installing AWWA Class B, D, E, & F Blind Flanges is straightforward and efficient, requiring simple alignment and bolting to the pipe flange. Their standardized dimensions and design facilitate easy integration into existing water infrastructure networks, minimizing installation time and labor costs.

-

Customization Options: AWWA Class B, D, E, & F Blind Flanges can be customized to meet specific project requirements, including size, pressure rating, and material composition. This customization flexibility allows for tailored solutions to address unique challenges or specifications in water distribution and treatment systems.