-

Cangzhou Yulong Steel Co., Ltd.

-

Phone:

+86 13303177267 -

Email:

admin@ylsteelfittings.com

- English

- Arabic

- Italian

- Spanish

- Portuguese

- German

- kazakh

- Persian

- Greek

- French

- Russian

- Polish

- Thai

- Indonesian

- Vietnamese

- Zulu

- Korean

- Uzbek

- Hindi

- Serbian

- Malay

- Ukrainian

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Miao

- Hungarian

- Icelandic

- igbo

- irish

- Japanese

- Javanese

- Kannada

- Khmer

- Rwandese

- Afrikaans

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Esperanto

- Estonian

- Finnish

- Frisian

- Galician

- Georgian

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Dutch

- Punjabi

- Romanian

- Samoan

- Scottish Gaelic

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Turkish

- Turkmen

- Urdu

- Uighur

- Welsh

- Bantu

- Yiddish

- Yoruba

డిసెం . 06, 2024 10:00 Back to list

stainless steel buttweld fittings

Stainless Steel Buttweld Fittings A Comprehensive Overview

Stainless steel buttweld fittings are essential components in piping systems, designed to provide seamless connections between pipes. These fittings are crucial in various industries, including oil and gas, chemical processing, food and beverage, and pharmaceuticals, due to their durability, corrosion resistance, and versatility.

What Are Stainless Steel Buttweld Fittings?

Buttweld fittings are designed to be welded directly to pipe ends to create a permanent, robust joint. Unlike threaded or slip-on fittings, which can sometimes weaken the pipe's integrity, buttweld fittings maintain the full strength of the piping system. They are available in various shapes, including elbows, tees, reducers, and caps, allowing for extensive flexibility in designing piping layouts.

Materials and Types

Stainless steel is favored for buttweld fittings due to its excellent mechanical properties and resistance to corrosion and high temperatures. Different grades of stainless steel are used, with 304 and 316 being the most common.

1. Grade 304 This is the most widely used stainless steel, known for its good corrosion resistance, formability, and weldability. It is ideal for general-purpose applications. 2. Grade 316 This grade is enriched with molybdenum, which enhances its resistance to pitting and crevice corrosion in chloride environments, making it suitable for marine applications and chemical processing.

Advantages of Stainless Steel Buttweld Fittings

One of the primary advantages of stainless steel buttweld fittings is their strength. When properly welded, these fittings create a joint that is as strong, if not stronger, than the pipes themselves. The absence of a threaded connection also reduces the likelihood of leaks, making the system more reliable.

Another significant advantage is their resistance to corrosion. Stainless steel does not rust or corrode easily, ensuring longevity and reduced maintenance costs. This property is particularly important in applications exposed to harsh environments or corrosive substances.

Buttweld fittings also contribute to smoother flow within the pipeline system. Their design minimizes turbulence and pressure drop, enhancing the efficiency of fluid and gas transport. This streamlined flow can lead to improved energy savings and better overall system performance.

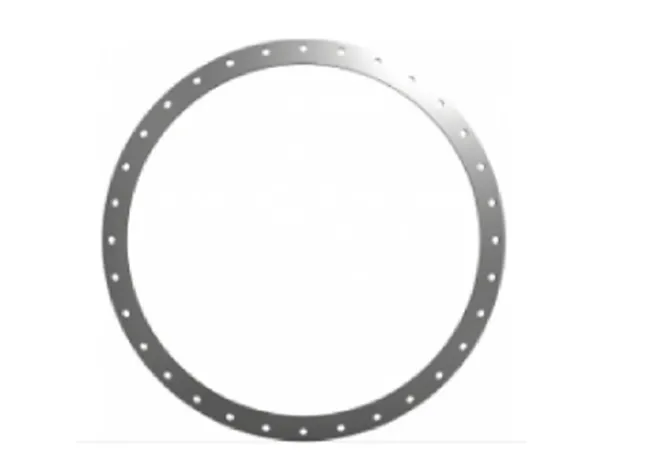

stainless steel buttweld fittings

Installation Process

Installing stainless steel buttweld fittings involves precise alignment and welding techniques. Typically, the process includes

1. Preparation This includes cutting the pipe ends to the correct length and ensuring that they are clean and free from contaminants.

2. Alignment Correctly aligning the fitting with the pipe is critical to ensure a strong weld joint.

3. Welding Various welding methods, such as TIG (Tungsten Inert Gas) or MIG (Metal Inert Gas), can be used based on the specific requirements. Proper heat control during welding is essential to avoid compromising the integrity of the stainless steel.

4. Inspection After welding, it’s vital to inspect and test the joints for leaks and structural integrity.

Applications

The versatility of stainless steel buttweld fittings makes them suitable for a wide range of applications. In the food and beverage industry, they are used in sanitary piping systems where hygiene is critical. In the oil and gas sector, they connect pipelines that transport crude oil and natural gas. Chemical manufacturers rely on these fittings to create systems that can handle harsh chemicals safely.

Conclusion

Stainless steel buttweld fittings provide a robust, reliable, and efficient solution for connecting pipes in numerous industries. Their strength, resistance to corrosion, and ability to facilitate smooth fluid flow make them an indispensable part of modern piping systems. As industries continue to evolve, the demand for high-quality stainless steel fittings is likely to grow, reinforcing their importance in engineering and manufacturing processes worldwide.

Latest news

-

ANSI 150P SS304 SO FLANGE

NewsFeb.14,2025

-

ASTM A333GR6 STEEL PIPE

NewsJan.20,2025

-

ANSI B16.5 WELDING NECK FLANGE

NewsJan.15,2026

-

ANSI B16.5 SLIP-ON FLANGE

NewsApr.19,2024

-

SABS 1123 FLANGE

NewsJan.15,2025

-

DIN86044 PLATE FLANGE

NewsApr.19,2024

-

DIN2527 BLIND FLANGE

NewsApr.12,2024

-

JIS B2311 Butt-Welding Fittings LR/SR 45°/90° /180°Seamless/Weld

NewsApr.23,2024