Key Characteristics:

1.Material Composition:

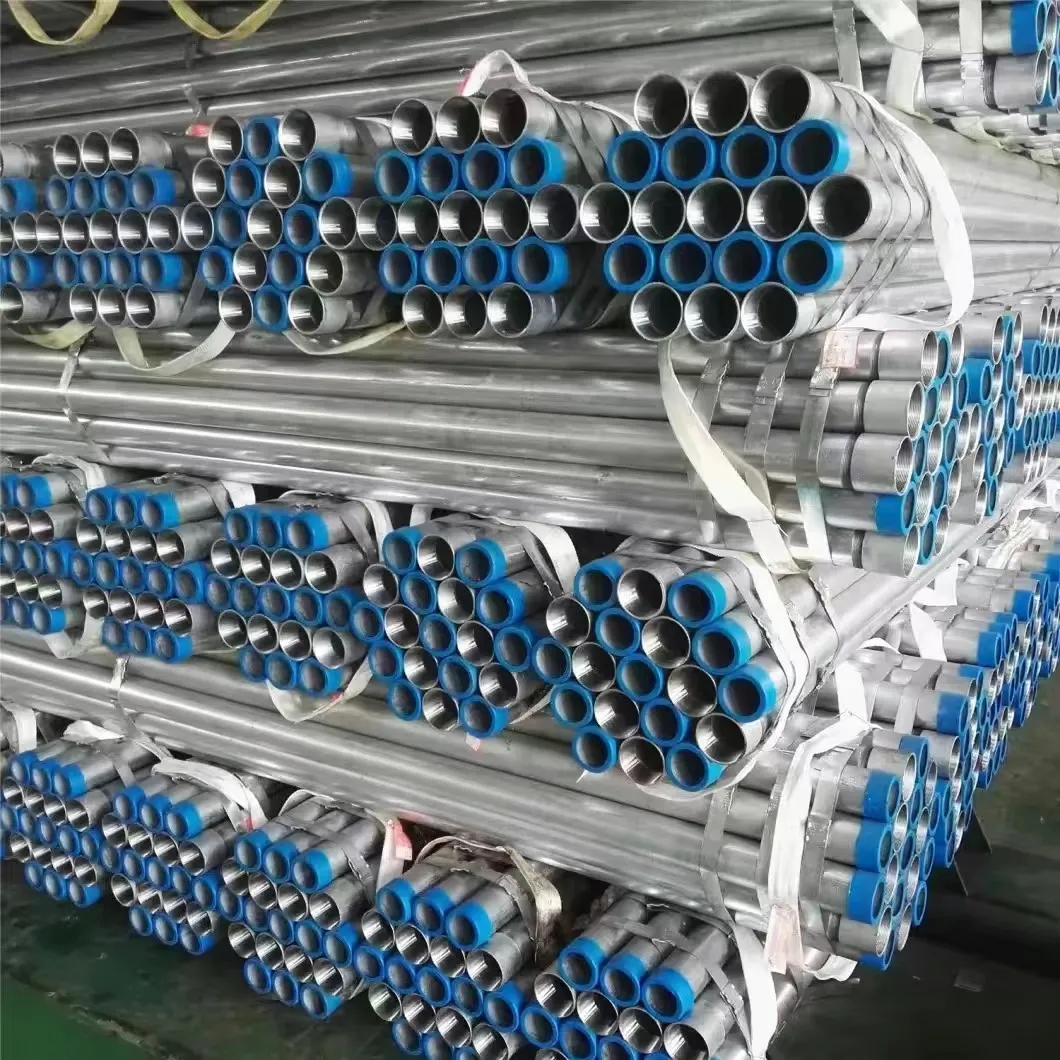

- -Galvanized iron pipes are typically made from carbon steel that has been galvanized. The galvanization process involves coating the steel with zinc to enhance its resistance to rust and corrosion.

- - Common grades of steel used include mild steel.

- 2. Manufacturing Process:

- - The steel pipes are produced through either seamless or welded processes.

- - After forming, the pipes are galvanized through hot-dip galvanizing (immersing them in molten zinc) or electro-galvanizing (applying a zinc coating through an electrochemical process).

- 3. Dimensions and Tolerances:

- - GI pipes are available in various sizes and schedules, which determine their wall thickness.

- - Common sizes include nominal diameters (e.g., ½ inch, 1 inch, 2 inches, etc.) and are categorized into different schedules (such as Schedule 40 and Schedule 80) based on the required strength and pressure ratings.

- 4. Threading:

- - Threading is done on the ends of the pipes to allow for the connection of joints and fittings. Threads are generally cut according to established standards, such as NPT (National Pipe Tapered), which ensures a tight and leak-proof fit.

- - Threads can be male (external) or female (internal), and various fittings (tees, elbows, and couplings) can be connected.

- 5. Corrosion Resistance:

- - The zinc coating provided during galvanization protects the underlying steel from oxidation and rust, greatly enhancing its lifespan, especially in outdoor or moisture-laden environments.

- - Over time, especially in harsh conditions, the zinc layer may wear away, necessitating regular inspections and maintenance.

- 6. Mechanical Properties:

- - GI pipes exhibit considerable tensile strength and ductility, making them suitable for various pressure applications.

- - The galvanization process does not drastically affect the mechanical properties of the underlying steel.

- 7. Applications:

- - Plumbing: Used for water supply lines, drainage systems, and other plumbing applications.

- - HVAC Systems: Often used in heating, ventilation, and air conditioning systems for both residential and commercial buildings.

- - Structural Support: In some cases, threaded GI pipes serve as supports or framing in construction.

- - Fire Sprinkler Systems: Commonly used in fire protection installations due to their durability and corrosion resistance.

- 8. Installation:

- - Installation of threaded GI pipes typically involves screwing the threaded ends into compatible fittings, often utilizing Teflon tape or pipe dope to ensure a secure, leak-proof connection.

- Summary:

- Threaded Galvanized Iron pipes are a widely used option for various applications requiring durability and resistance to corrosion. Their ability to be easily connected via threads makes them highly versatile in plumbing and industrial systems. When working with GI pipes, it's essential to consider the appropriate dimensions, threading standards, and application requirements to ensure a safe and reliable installation. Regular maintenance and inspection are also recommended to prolong the life of the system and identify any potential issues, such as wear of the zinc coating.

Write your message here and send it to us