Flange Manufacturing Process

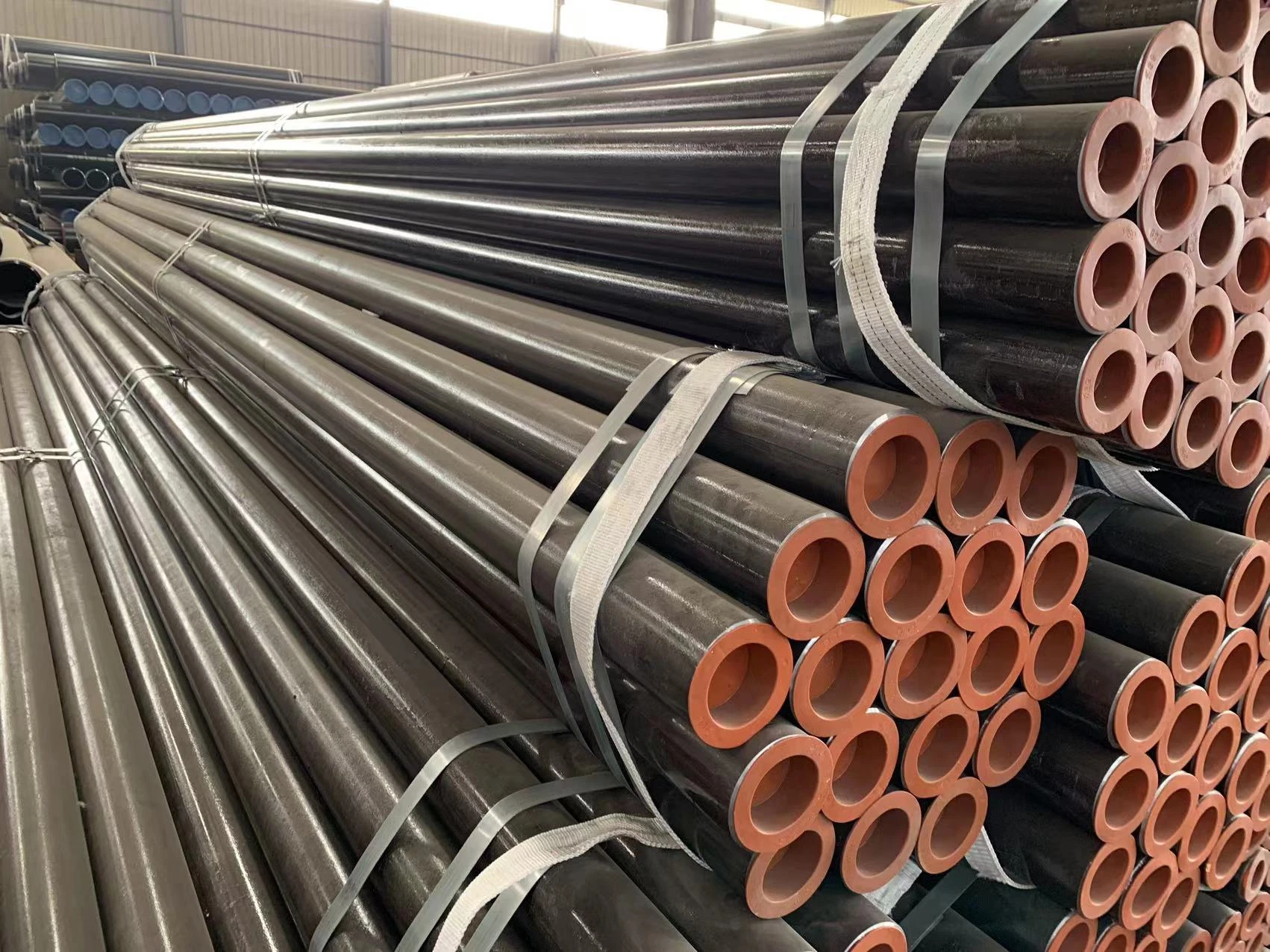

Our hardware tools and flanges are produced through precision engineering and strict quality control. The process begins with high-grade steel selection, followed by CNC machining, forging, or casting to ensure dimensional accuracy. Advanced heat treatment enhances durability, while surface treatments (e.g., galvanizing, powder coating) provide corrosion resistance. Each product undergoes rigorous testing for pressure tolerance, hardness, and fit. Automated packaging ensures safe delivery. Combining modern technology with skilled craftsmanship, we guarantee reliable, ISO-certified products for global industrial applications.