-

Cangzhou Yulong Steel Co., Ltd.

-

Phone:

+86 13303177267 -

Email:

admin@ylsteelfittings.com

- English

- Arabic

- Italian

- Spanish

- Portuguese

- German

- kazakh

- Persian

- Greek

- French

- Russian

- Polish

- Thai

- Indonesian

- Vietnamese

- Zulu

- Korean

- Uzbek

- Hindi

- Serbian

- Malay

- Ukrainian

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Miao

- Hungarian

- Icelandic

- igbo

- irish

- Japanese

- Javanese

- Kannada

- Khmer

- Rwandese

- Afrikaans

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Esperanto

- Estonian

- Finnish

- Frisian

- Galician

- Georgian

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Dutch

- Punjabi

- Romanian

- Samoan

- Scottish Gaelic

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Turkish

- Turkmen

- Urdu

- Uighur

- Welsh

- Bantu

- Yiddish

- Yoruba

فېۋرال . 14, 2025 04:46 Back to list

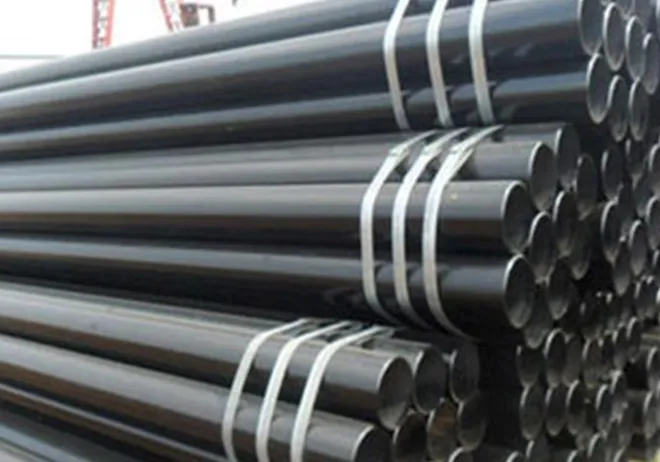

2 inch galvanized pipe for sale

Galvanized pipes have long been recognized as a staple in plumbing and construction due to their durability and resistance to corrosion. The 36 galvanized pipe stands out particularly because of its robust application in industrial settings. With its substantial diameter, it's extensively employed in large-scale projects that demand reliability and endurance. Here's why the 36 galvanized pipe remains unrivaled in its field, driven by both practical experience and technical expertise.

Moreover, real-world experience has shown that choosing 36 galvanized pipe is an economically sound decision. The initial investment may be higher compared to non-galvanized alternatives, but the cost benefits manifest over time through reduced maintenance expenses and extended service life. This strategic advantage has been documented in numerous case studies where long-term infrastructural projects have realized significant savings and efficiency. Manufacturers and distributors of 36 galvanized pipes are keenly aware of their responsibility to provide a product that exceeds the expectations of professionals. As a result, these companies commit to continual improvement and innovation in their galvanization techniques and material sourcing. This dedication results in not only a superior product but also in maintaining the ethical standards that reinforce customer trust. For those seeking to procure 36 galvanized pipes, it is crucial to consult with reputable suppliers who can offer expert guidance tailored to specific project requirements. Understanding the nuances of installation, environmental considerations, and long-term performance will ensure that organizations make informed decisions that align with their operational goals. In conclusion, the 36 galvanized pipe remains an indispensable component in industries demanding high-quality, durable, and reliable materials. Its unmatched performance in various applications highlights why it continues to be a trusted choice among professionals. By combining experience, expertise, authority, and trustworthiness, the 36 galvanized pipe not only meets but often exceeds the demanding standards of modern infrastructure projects.

Moreover, real-world experience has shown that choosing 36 galvanized pipe is an economically sound decision. The initial investment may be higher compared to non-galvanized alternatives, but the cost benefits manifest over time through reduced maintenance expenses and extended service life. This strategic advantage has been documented in numerous case studies where long-term infrastructural projects have realized significant savings and efficiency. Manufacturers and distributors of 36 galvanized pipes are keenly aware of their responsibility to provide a product that exceeds the expectations of professionals. As a result, these companies commit to continual improvement and innovation in their galvanization techniques and material sourcing. This dedication results in not only a superior product but also in maintaining the ethical standards that reinforce customer trust. For those seeking to procure 36 galvanized pipes, it is crucial to consult with reputable suppliers who can offer expert guidance tailored to specific project requirements. Understanding the nuances of installation, environmental considerations, and long-term performance will ensure that organizations make informed decisions that align with their operational goals. In conclusion, the 36 galvanized pipe remains an indispensable component in industries demanding high-quality, durable, and reliable materials. Its unmatched performance in various applications highlights why it continues to be a trusted choice among professionals. By combining experience, expertise, authority, and trustworthiness, the 36 galvanized pipe not only meets but often exceeds the demanding standards of modern infrastructure projects.

Latest news

-

ANSI 150P SS304 SO FLANGE

NewsFeb.14,2025

-

ASTM A333GR6 STEEL PIPE

NewsJan.20,2025

-

ANSI B16.5 WELDING NECK FLANGE

NewsJan.15,2026

-

ANSI B16.5 SLIP-ON FLANGE

NewsApr.19,2024

-

SABS 1123 FLANGE

NewsJan.15,2025

-

DIN86044 PLATE FLANGE

NewsApr.19,2024

-

DIN2527 BLIND FLANGE

NewsApr.12,2024

-

JIS B2311 Butt-Welding Fittings LR/SR 45°/90° /180°Seamless/Weld

NewsApr.23,2024