Specifications and Materials

ASTM A333 steel pipes are available in a variety of specifications to suit different application requirements. Common specifications include 684, 283, 24*2.5, etc. Other specifications can also be customized according to customer needs. In terms of materials, ASTM A333 steel pipes are mainly made of alloy steel and stainless steel, including:

Alloy steel

ASTM/ASMEA234WP1-WP12-WP11-WP22-WP5-WP91-WP911

Stainless steel

ASTM/ASMEA403WP304-304L-304H-304LN-304NASTM/ASMEA403WP316-316L-316H-316LN-316N-316TiASTM/ASMEA403WP321-321HASTM/ASMEA403WP347-347H1

Wall thickness and surface treatment

Wall thickness range

ASTM A333 steel pipes have a wide range of wall thicknesses, ranging from standard SCH10 to larger SCH160, and some large wall thicknesses can reach 150mm.

Surface treatment methods

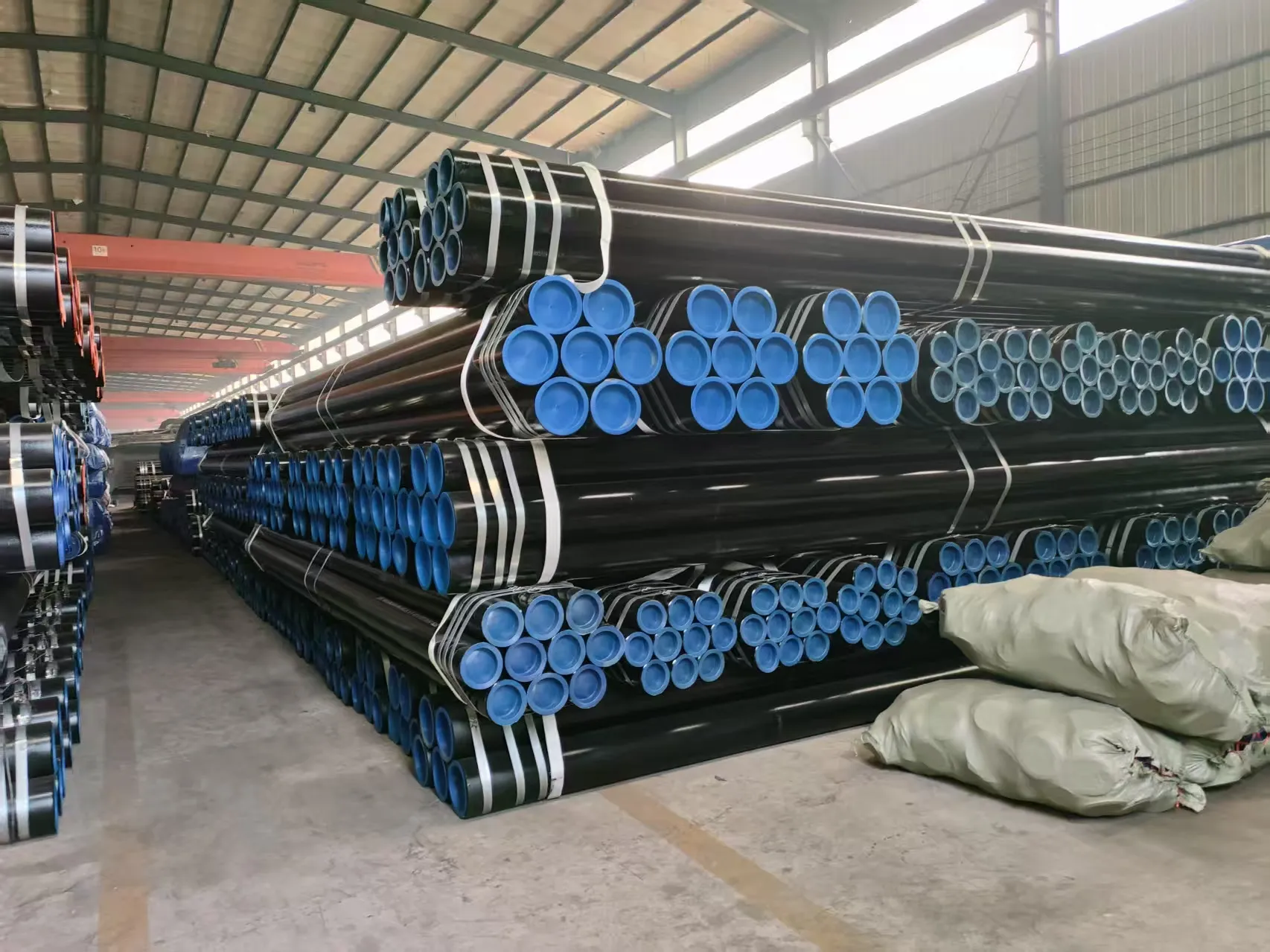

In order to improve corrosion resistance and service life, ASTM A333 steel pipes can be subjected to a variety of surface treatments, including anti-rust black paint, anti-rust varnish, transparent anti-rust oil, hot-dip galvanizing, cold-dip galvanizing, sandblasting, 3PE coating and epoxy coating.

Application fields

Due to its excellent performance, ASTM A333 steel pipes are widely used in many fields:

Main application fields

Power industry

Oil and gas industry

Chemical industry

Shipbuilding

Heating system

Papermaking industry

Metallurgical industry

Construction industry

Pharmaceutical industry1

Quality certification and packaging

Quality certification

The production of ASTM A333 steel pipes has passed ISO9001 international certification, effectively controlling the entire production process, and obtained the special equipment manufacturing license of the People's Republic of China.

Packaging methods

Common packaging methods include wooden box packaging, pallet packaging and fumigation-free wooden box packaging, which can also be customized according to the specific requirements of customers.

Market supply situation

There are many companies in the market that specialize in the production of ASTM A333 steel pipes and their accessories, such as elbows, flanges, tees, reducers, etc. The products provided by these companies not only meet multiple domestic and international standards, but also have good corrosion resistance and mechanical properties, which can meet the needs of different customers.

In summary, ASTM A333 steel pipes play an important role in many industries due to their wide range of uses, diverse specifications, high-quality materials and strict quality control.