-

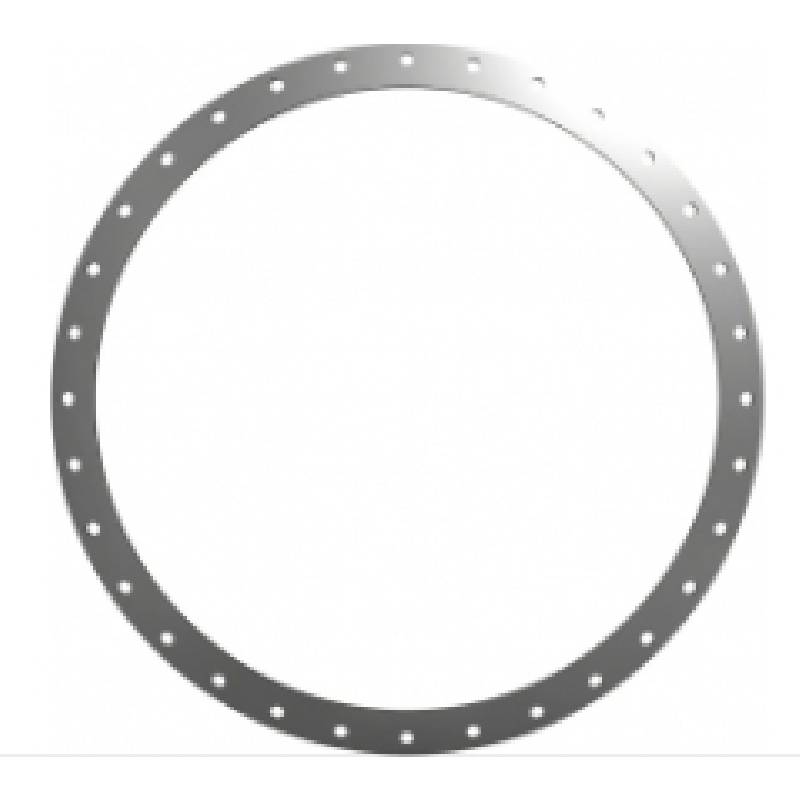

坚固的设计: DIN 86044 板式法兰具有扁平的圆形板,其周边均匀分布有螺栓孔。这种设计便于对准和螺栓固定到配对法兰上,从而提供坚固稳定的连接,可承受海洋环境中的动态条件,包括振动和压力波动。

-

耐腐蚀性能: DIN 86044 板法兰采用碳钢、不锈钢或合金钢等高品质材料制成,具有出色的耐腐蚀性,确保在经常暴露于盐水和恶劣天气条件的海洋应用中具有耐用性和使用寿命。

-

海水兼容性: DIN 86044 板式法兰专为满足海水应用的严格要求而设计。其耐腐蚀材料和坚固结构使其成为船舶、海上平台和海洋结构上海水管道系统的理想选择,这些系统的可靠性和性能至关重要。

-

精密工程: DIN 86044 板式法兰经过精密加工和工程工艺,以满足严格的尺寸公差和表面光洁度要求。这种精度确保了与其他 DIN 86044 标准法兰的兼容性和互换性,便于无缝集成到船舶管道系统中,并最大限度地降低泄漏或故障风险。

-

安装简便: 安装 DIN 86044 板式法兰既高效又简单,只需简单对准并用螺栓固定到配合法兰即可。其标准化尺寸和设计便于轻松集成到现有船舶管道网络中,从而最大限度地缩短安装时间和降低人工成本。

主要特征:

- 适合海洋应用的坚固设计

- 耐腐蚀,在海水环境中持久耐用

- 海水兼容性,可靠性能

- 精密工程,确保严格公差

- 只需简单对准和螺栓固定即可轻松安装

Din 86044 Flange Dimensions

| Size (Inch) |

NB (mm) |

管道 (mm) |

A (mm) |

B (mm) |

C (mm) |

D Number of holes |

E Diameter of holes(mm) |

F (mm) |

Weight (kg) |

| 10 | 250 | 273.0 | 276 | 335 | 375 | 12 | 18 | 16 | 6 |

| 12 | 300 | 323.9 | 327 | 395 | 440 | 12 | 22 | 16 | 8 |

| 14 | 350 | 355.6 | 360 | 445 | 490 | 12 | 22 | 16 | 10 |

| 16 | 400 | 406.4 | 411 | 495 | 540 | 16 | 22 | 16 | 11 |

| 18 | 450 | 457.2 | 461 | 550 | 595 | 16 | 22 | 16 | 13 |

| 20 | 500 | 508.0 | 512 | 600 | 645 | 20 | 22 | 16 | 14 |

| 22 | 550 | 560.0 | 563 | 650 | 703 | 20 | 22 | 20 | 20 |

| 24 | 600 | 609.6 | 614 | 700 | 754 | 20 | 22 | 20 | 22 |

| 26 | 650 | 664.0 | 665 | 750 | 805 | 20 | 22 | 20 | 24 |

| 28 | 700 | 711.2 | 716 | 800 | 856 | 24 | 22 | 20 | 25 |

| 30 | 750 | 762.0 | 767 | 860 | 907 | 24 | 22 | 20 | 27 |

| 32 | 800 | 812.8 | 818 | 900 | 958 | 24 | 22 | 20 | 29 |

| 36 | 900 | 914.4 | 920 | 1010 | 1060 | 28 | 22 | 20 | 32 |

| 38 | 950 | 698.0 | 970 | 1060 | 1110 | 28 | 22 | 20 | 34 |

| 40 | 1000 | 1016.0 | 1022 | 1110 | 1167 | 32 | 22 | 20 | 36 |

| 44 | 1100 | 1120.0 | 1126 | 1210 | 1266 | 32 | 22 | 20 | 39 |

| 48 | 1200 | 1220.0 | 1226 | 1310 | 1366 | 36 | 22 | 20 | 42 |

| 52 | 1300 | 1324.0 | 1326 | 1410 | 1466 | 40 | 22 | 20 | 45 |

The Advantages of DIN 86044 Flanges

When it comes to industrial applications, the DIN 86044 flange holds a significant advantage due to its robust design and superior functionality. These flanges are primarily used in piping systems, providing reliable connections that are both secure and efficient. One of the most notable benefits of the DIN 86044 flange is its compatibility with a variety of materials, including steel, stainless steel, and plastic, making it a versatile choice for manufacturers and engineers alike.

Moreover, the DIN 86044 flange excels in durability. Its design incorporates high resistance to pressure and temperature fluctuations, which is crucial for systems that operate under extreme conditions. This reliability translates to lower maintenance costs over time, as fewer replacements are necessary compared to less durable alternatives.

Another key advantage is the standardization of the DIN 86044 flange. Being conformant to international standards means that these flanges can be seamlessly integrated into existing systems, facilitating easy upgrades and expansions without the need for extensive redesigns.

In conclusion, the DIN 86044 flange stands out in the market for its strength, versatility, and compatibility. By choosing this flange, businesses can ensure that their piping systems maintain peak efficiency and durability, ultimately contributing to smoother operations and reduced downtime.

FAQs About DIN 86044 Flanges

1. What are DIN 86044 flanges?

DIN 86044 flanges are specific types of din flange that adhere to the standards set by the German Institute for Standardization (DIN). They are designed for use in various industrial applications, particularly those requiring reliable and secure 管道 connections.

2. What materials are DIN 86044 flanges made from?

DIN 86044 flanges can be made from a variety of materials, including:

Carbon steel

Stainless steel

Alloy steel

Other materials are suitable for specific industrial requirements.

3. What applications are DIN 86044 flanges suitable for?

These flanges are commonly used in:

Oil and gas industries

Petrochemical plants

Chemical processing

Power generation

Water treatment facilities

4. How should DIN 86044 flanges be maintained?

Maintenance tips include:

Regular inspections for signs of wear, corrosion, or damage

Proper cleaning to prevent the buildup of contaminants

Ensuring bolts and gaskets are correctly fitted and in good condition

Following manufacturer guidelines for specific maintenance procedures

5. Can DIN 86044 flanges be customized?

Yes, DIN 86044 flanges can be customized to meet specific requirements, including modifications in size, material, and design to suit particular industrial applications.

DIN 86044 Flange Standard

In the realm of engineering and manufacturing, ensuring compliance with established standards is crucial for maintaining safety and reliability. One such standard that carries significant importance is the DIN 86044 flange standard. This German standard is widely recognized for its specifications regarding the design, dimensions, and performance criteria for flanges utilized in various industrial applications.

The DIN 86044 flange standard outlines the essential characteristics of common flange types, which serve as critical components in piping systems, pumps, valves, and fittings. These flanges facilitate the seamless connection of different sections of pipe, ensuring the integrity of the overall system. The standard specifies dimensions such as bolt-hole patterns, thickness, and outer diameter, which help manufacturers produce flanges that are interchangeable with others in the market.

One key aspect of the DIN 86044 flange standard is its focus on compatibility. By adhering to this standard, manufacturers can ensure that their flanges effectively align with those produced by other companies, thus minimizing the risk of leaks and failures in systems under pressure. The standard also includes material specifications, ensuring that flanges can withstand various environmental conditions while maintaining their structural integrity.

Furthermore, the adoption of the DIN 86044 flange standard enhances safety in industrial operations. By utilizing flanges that meet this standard, engineers and project managers can be confident that their systems are compliant with international safety regulations. This not only protects workers but also prevents costly downtime due to equipment failure.

Corrosion Resistance of DIN 86044 Flanges in Saltwater Environments

The use of DIN 86044 flanges in various industrial applications is widespread, particularly in marine and saltwater environments. Understanding the corrosion resistance of these flanges is crucial for ensuring the longevity and reliability of piping systems.

DIN 86044 flanges are typically manufactured from carbon steel or stainless steel, with the latter being the preferred choice for saltwater applications due to its superior corrosion resistance. Stainless steel grades, especially those with higher chromium and molybdenum content, offer excellent protection against pitting and crevice corrosion, which are common issues in saline environments.

The corrosion resistance of DIN 86044 flanges is not merely a function of the material composition but also depends on the surface finish and any protective coatings that may be applied. Proper surface treatment increases the resistance to corrosive agents present in saltwater, thereby extending the lifespan of the flanges. Moreover, regular maintenance and inspection can help identify early signs of corrosion, allowing for timely interventions to prevent significant damage.

When selecting DIN 86044 flanges for saltwater applications, it is essential to consider the specific environmental conditions, including salinity levels and temperature fluctuations. Engineers and procurement specialists must choose flanges that meet or exceed the required standards for corrosion resistance to ensure optimal performance.

In conclusion, DIN 86044 flanges provide a dependable solution for piping systems operating in saltwater environments when appropriate materials and precautions are employed. Understanding their corrosion resistance properties is vital for minimizing downtime and enhancing system efficiency. By selecting the right DIN 86044 flange and implementing a proactive maintenance strategy, industries can safeguard their assets from the detrimental effects of corrosion.

Installation Guide for DIN 86044 Flanges: Ensuring Proper Fit and Seal

When it comes to industrial applications, selecting the right components is crucial for ensuring efficiency and safety. Among these, the DIN 86044 flange has emerged as a favored choice for many engineers and technicians due to its robust design and compatibility with various piping systems. This guide aims to provide essential steps for the proper installation of DIN 86044 flanges, ensuring a reliable fit and seal.

Step 1: Preparation

Before proceeding with the installation, it’s imperative to inspect both the DIN 86044 flange and the mating surfaces. Ensure that both flanges are free from any debris, rust, or imperfections. Clean any remaining residue thoroughly to guarantee a proper seal. Additionally, check for alignment of the pipes, as misalignment can lead to leaks or failures under pressure.

Step 2: Gasket Selection

Choose an appropriate gasket suitable for your application and the medium it will carry. The gasket acts as a seal between the two mating flanges and is crucial for preventing leakage. For DIN 86044 flanges, it’s advisable to opt for gaskets that can withstand the specific temperature and pressure conditions they will face.

Step 3: Bolt Tightening

Once both the flange surfaces and gaskets are properly prepared, align the flanges and insert the bolts. It is critical to follow the recommended bolt-tightening sequence to ensure even pressure and a secure seal. The tightening should be done progressively, using a torque wrench to achieve the specified torque level for the DIN 86044 flange.

By following this installation guide, you can ensure that your DIN 86044 flanges are fitted properly and sealed effectively. The right installation practices not only enhance the reliability of your piping system but also extend the lifespan of the components involved. For further information or specific technical support regarding DIN 86044 flanges, consult with industry professionals to ensure optimal performance in your applications.