-

Cangzhou Yulong Steel Co., Ltd.

-

Phone:

+86 13303177267 -

Email:

admin@ylsteelfittings.com

- English

- Arabic

- Italian

- Spanish

- Portuguese

- German

- kazakh

- Persian

- Greek

- French

- Russian

- Polish

- Thai

- Indonesian

- Vietnamese

- Zulu

- Korean

- Uzbek

- Hindi

- Serbian

- Malay

- Ukrainian

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Miao

- Hungarian

- Icelandic

- igbo

- irish

- Japanese

- Javanese

- Kannada

- Khmer

- Rwandese

- Afrikaans

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Esperanto

- Estonian

- Finnish

- Frisian

- Galician

- Georgian

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Dutch

- Punjabi

- Romanian

- Samoan

- Scottish Gaelic

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Turkish

- Turkmen

- Urdu

- Uighur

- Welsh

- Bantu

- Yiddish

- Yoruba

Jun . 10, 2025 11:11 Back to list

42 Inch Pipe Cap – Durable Steel Pipe Caps Weld On & Custom Sizes Available

Ever been faced with downtime due to poor pipe end protection? It happens more than you think. According to 2023 industry statistics, pipe failures and leaks account for over $286 million in losses annually in the United States—often due to inadequate end capping. If you are involved in industrial piping, oil & gas, or large-scale construction, you know the stress. The need for a reliable 42 inch pipe cap

or that perfect 4 inch weld on pipe cap is more crucial than ever. Safety, cost-efficiency, and project timelines hinge on your choice. Are you ready to discover the ultimate solution?

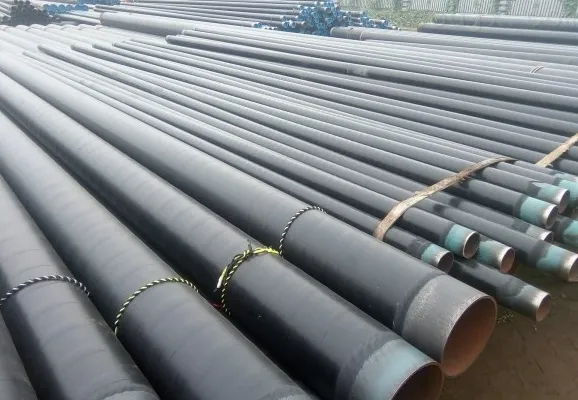

(42 inch pipe cap)

Unmatched Technical Advantages of the 42 Inch Pipe Cap

If you’ve worked with heavy-duty pipelines, you understand one thing: not all pipe caps are created equal. Our 42 inch pipe cap is designed for high-impact use. It's engineered with premium ASTM A234 WPB carbon steel. This means greater durability, minimal corrosion, and impressive resistance to hostile industrial environments.

Our proprietary weld on technology ensures a watertight fit. Integration is easy. Installation? Fast and secure. And if you need something smaller, like a 4 inch steel pipe cap, you get the same craftsmanship across the range. See the key technical specs:

Ready to avoid costly downtime? Want a weld on pipe cap that just fits and stays? Our technology delivers exactly what you need—without compromise.

Manufacturer Comparison: Where Does Our 42 Inch Pipe Cap Stand Out?

Let’s compare. The market is flooded with options—but only a few manufacturers offer both quality and reliability. Here's a head-to-head comparison:

Ask yourself: Why settle for less? With our 42 inch pipe cap, you get peace of mind—a standard other brands just can't match.

Customized Solutions: Your Project, Your Dimensions, Your Way

No two jobs are the same. Sometimes you need a 4 inch weld on pipe cap for tight spots. Other times, your operation demands a heavy-duty, oversized solution. Guess what? We fabricate 100% custom pipe caps for any diameter, thickness, or alloy. Just send us the drawing. We'll turn it around, fast.

Choose from carbon steel, 304 or 316 stainless steel, alloy steels, and more. Different standards? We offer ASME, ANSI, DIN, JIS certified caps. Our digital production line uses CNC plasma-cutting, so you get a flawless fit—every time.

Application Case: How a 42 Inch Pipe Cap Saved a $10M Project

Here’s a real scenario. In June 2022, a major U.S. water company was set to install a new 42 inch pipeline—crucial for their infrastructure. But the original pipe ends were unprotected. During storage, contaminants entered the pipes, leading to delays and extra cost. Our 42 inch pipe caps were delivered within 14 days of order. Each cap was CNC made to spec, tested, and delivered pre-coated. Result: The project team re-opened the site ahead of schedule. No pipe replacement, no lost profits, and zero safety incidents. That's the kind of assurance you can count on, whatever your sector.

Conclusion: Choose the 42 Inch Pipe Cap Leader for Ultimate Security

Every pipeline project tells a story. Yours should be one of zero leaks, punctual timelines, and ultimate safety. Whether you need a full range from 4 inch steel pipe caps to robust 42 inch weld on caps, don’t play roulette with quality.

Ready to transform your pipeline performance? Contact SteelGuard Industries today. We’re America’s leading manufacturer of heavy-duty pipe caps. We offer 5-year warranties, rapid production, and custom engineering support—no gimmicks, just real industry-grade solutions.

Call us now or request a free quote online. Don’t wait. Give your project—and your reputation—the protection it deserves.

Professional FAQs on Pipe Caps

Q1: What is a 42 inch pipe cap used for?

A: A 42 inch pipe cap is designed to seal the end of a 42 inch diameter pipe. It prevents leaks, corrosion, and entry of debris. It's critical for large-scale water, oil, and gas pipelines, especially during transport or storage.

Q2: How does a 4 inch steel pipe cap compare with a 4 inch weld on pipe cap?

A: Both serve to seal 4 inch pipes. The key difference: a steel pipe cap may be threaded or welded, while a weld-on pipe cap is permanently attached by welding, offering higher pressure protection and durability.

Q3: What materials are best for 42 inch weld on pipe caps?

A: Premium carbon steel (ASTM A234 WPB) or stainless steels (304/316) offer the best durability. These materials handle pressure, corrosion, and temperature variations well.

Q4: Can I get a custom-sized 42 inch pipe cap?

A: Absolutely. We offer custom fabrication. Just send us the dimensions, material choice, and standard required. We’ll make it to order.

Q5: What is the lead time for a large diameter pipe cap order?

A: Standard sizes ship in 2-3 weeks. Custom orders may take 3-4 weeks, depending on volume and specs.

Q6: Are your pipe caps tested for leaks and pressure?

A: Yes. Every 42 inch pipe cap undergoes 100% hydrostatic testing for pressure and leaks before delivery. Certification is available upon request.

Q7: How do I install a weld on pipe cap?

A: Position the cap flush to the pipe end, tack weld in four locations, then fully weld around the circumference. Always follow your project's welding standard for best results and longevity.

(42 inch pipe cap)

FAQS on 42 inch pipe cap

Q: What is a 42 inch pipe cap used for?

A: A 42 inch pipe cap is used to cover or seal the end of a 42 inch diameter pipe. It helps prevent debris, liquids, or gases from entering the pipe. This cap is essential in piping systems for safety and maintenance.

Q: Can a 4 inch steel pipe cap be welded onto a pipe?

A: Yes, a 4 inch steel pipe cap can be welded onto a pipe. This provides a secure and permanent seal for 4-inch steel pipes. It is ideal for high-pressure or industrial applications.

Q: What is the difference between a 4 inch weld on pipe cap and a threaded cap?

A: A 4 inch weld on pipe cap is designed to be permanently welded to the pipe. In contrast, a threaded cap is removable and screws onto threaded pipe ends. The choice depends on maintenance and application needs.

Q: Are 42 inch pipe caps available in different materials?

A: Yes, 42 inch pipe caps are made from materials like carbon steel, stainless steel, or PVC. The material depends on the application and environmental factors. Always choose a material compatible with the piping system.

Q: How do I measure for a 4 inch steel pipe cap?

A: Measure the outside diameter of your pipe, which should be about 4 inches. This measurement ensures the cap fits securely over the pipe end. Always confirm pipe schedule and material compatibility as well.

Latest news

-

ANSI 150P SS304 SO FLANGE

NewsFeb.14,2025

-

ASTM A333GR6 STEEL PIPE

NewsJan.20,2025

-

ANSI B16.5 WELDING NECK FLANGE

NewsJan.15,2026

-

ANSI B16.5 SLIP-ON FLANGE

NewsApr.19,2024

-

SABS 1123 FLANGE

NewsJan.15,2025

-

DIN86044 PLATE FLANGE

NewsApr.19,2024

-

DIN2527 BLIND FLANGE

NewsApr.12,2024

-

JIS B2311 Butt-Welding Fittings LR/SR 45°/90° /180°Seamless/Weld

NewsApr.23,2024