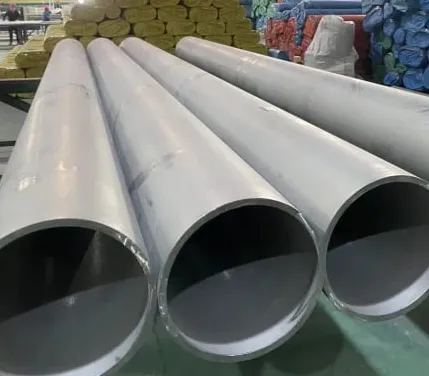

Stainless Steel 304 Seamless Pipe/ ASTM A312 TP 304 Chemical element

Carbon (C) : ≤0.08%, low carbon content can reduce the precipitation of chromium carbide, avoid intergranular corrosion, help to maintain the corrosion resistance of the material.

Silicon (Si) : ≤1.00%, silicon in steel mainly plays a role in deoxidation and improving the strength and hardness of steel, and also has a positive impact on the corrosion resistance of steel.

Manganese (Mn) : ≤2.00%, manganese can improve the strength and toughness of steel, but also improve the thermal processing performance of steel, to a certain extent, enhance the corrosion resistance of steel.

Phosphorus (P) : ≤0.045%, phosphorus is a harmful element, the content is too high will lead to the toughness of steel decline, increase the cold brittleness, so the need to strictly control its content.

Sulfur (S) : ≤0.030%, sulfur is also a harmful element, will cause steel to produce thermal brittleness, reduce the toughness and corrosion resistance of steel, need to be strictly limited.

Nickel (Ni) : 8.00%-11.00%, nickel is the main element in the formation of austenite, which can improve the strength, toughness, corrosion resistance and high temperature performance of steel, so that steel has good low temperature toughness and fatigue resistance.

Chromium (Cr) : 18.00%-20.00%, chromium is the key element that determines the corrosion resistance of stainless steel, can form a dense chromium oxide protective film on the surface of steel, effectively prevent the erosion of oxygen and corrosive media, and improve the oxidation resistance and corrosion resistance of steel.

Stainless Steel 304 Seamless Pipe/ ASTM A312 TP 304 Mechanical property

Tensile strength: ≥520MPa, which means that the maximum stress value that the material can withstand when it is stretched to break is higher, and it can withstand a larger tensile force without breaking, which is suitable for occasions that bear a larger external force.

Yield strength: ≥210MPa, the material begins to produce obvious plastic deformation when the minimum stress value reaches this standard, to ensure that the pipe under a certain pressure and external force, plastic deformation will not occur prematurely, to ensure the safety of use.

Elongation: heat treatment ≥35%, non-heat treatment ≥25%. The elongation ratio reflects the plasticity of the material, and the high value indicates that the material can withstand large deformation without breaking before breaking, has good flexibility and impact resistance, and can adapt to different installation and use environments.

-

Кампанія Cangzhou Yulong Steel Co., Ltd.

-

тэлефон:

+86 13303177267 -

электронная пошта:

admin@ylsteelfittings.com

- англійская

- арабская

- італьянскі

- Іспанскі

- партугальская

- нямецкі

- казахская

- фарсі

- грэцкі

- французскі

- рускі

- польскі

- Тайская

- інданезійскі

- в'етнамская

- Зулу

- карэйская

- узбекская

- не

- сербская

- малайская

- украінскі

- Гуджараці

- Гаіцянская крэольская

- хаўса

- гавайскі

- іўрыт

- Мяо

- венгерскі

- ісландская

- ігбо

- ірландскі

- Японскі

- яванскі

- каннада

- кхмерская

- Руандыйскі

- афрыканскі

- албанец

- Амхарская

- армянская

- Азербайджанская

- Баскская

- беларускі

- бенгальская

- басьнійскі

- балгарская

- каталонскі

- себуанскі

- Кітай

- Кітай (Тайвань)

- карсіканскі

- харвацкая

- чэшскі

- дацкая

- Эсперанта

- эстонскі

- фінская

- фрызская

- галісійскі

- грузінскі

- курдская

- кіргізская

- Сухоты

- лацінка

- Латышскі

- літоўскі

- Люксембургскі

- Македонская

- Малгашы

- Малаялам

- мальтыйская

- Маоры

- Маратхі

- Мангольская

- М'янма

- непальская

- нарвежская

- нарвежская

- аксітанская

- пушту

- галандскі

- Панджабі

- румынская

- самаанская

- шатландская гэльская

- англійская

- шона

- сіндхі

- сінгальская

- славацкая

- Славенская

- самалійская

- сунданская

- Суахілі

- шведская

- тагальская

- таджыкская

- тамільская

- татарскі

- Тэлугу

- турэцкі

- туркменскі

- Урду

- уйгурскі

- валійская

- Даведка

- Ідыш

- ёруба

Напішыце тут сваё паведамленне і адпраўце яго нам

Related News

-

Jul . 02, 2025The Ultimate Guide to Selecting Stainless Steel Bends: Specification Analysis and Industrial Applications Under ASTM A234 StandardIn the realm of industrial piping systems, stainless steel bends stand as critical components that ensure seamless fluid flow and structural integrity.

-

Jul . 02, 2025The Cost-Effectiveness Code of K55 Grade: How API 5CT Pipe Optimizes Cost and Performance for Conventional Oil WellsIn the oil and gas industry, balancing operational costs with reliable performance in conventional oil wells is a constant challenge.