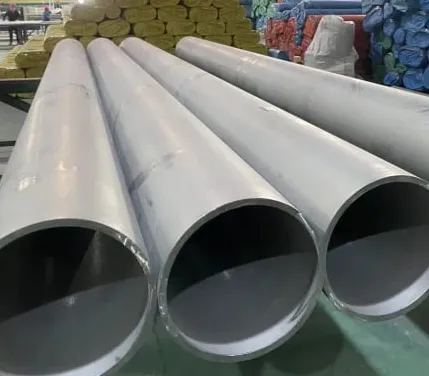

Stainless Steel 304 Seamless Pipe/ ASTM A312 TP 304 Chemical element

Carbon (C) : ≤0.08%, low carbon content can reduce the precipitation of chromium carbide, avoid intergranular corrosion, help to maintain the corrosion resistance of the material.

Silicon (Si) : ≤1.00%, silicon in steel mainly plays a role in deoxidation and improving the strength and hardness of steel, and also has a positive impact on the corrosion resistance of steel.

Manganese (Mn) : ≤2.00%, manganese can improve the strength and toughness of steel, but also improve the thermal processing performance of steel, to a certain extent, enhance the corrosion resistance of steel.

Phosphorus (P) : ≤0.045%, phosphorus is a harmful element, the content is too high will lead to the toughness of steel decline, increase the cold brittleness, so the need to strictly control its content.

Sulfur (S) : ≤0.030%, sulfur is also a harmful element, will cause steel to produce thermal brittleness, reduce the toughness and corrosion resistance of steel, need to be strictly limited.

Nickel (Ni) : 8.00%-11.00%, nickel is the main element in the formation of austenite, which can improve the strength, toughness, corrosion resistance and high temperature performance of steel, so that steel has good low temperature toughness and fatigue resistance.

Chromium (Cr) : 18.00%-20.00%, chromium is the key element that determines the corrosion resistance of stainless steel, can form a dense chromium oxide protective film on the surface of steel, effectively prevent the erosion of oxygen and corrosive media, and improve the oxidation resistance and corrosion resistance of steel.

Stainless Steel 304 Seamless Pipe/ ASTM A312 TP 304 Mechanical property

Tensile strength: ≥520MPa, which means that the maximum stress value that the material can withstand when it is stretched to break is higher, and it can withstand a larger tensile force without breaking, which is suitable for occasions that bear a larger external force.

Yield strength: ≥210MPa, the material begins to produce obvious plastic deformation when the minimum stress value reaches this standard, to ensure that the pipe under a certain pressure and external force, plastic deformation will not occur prematurely, to ensure the safety of use.

Elongation: heat treatment ≥35%, non-heat treatment ≥25%. The elongation ratio reflects the plasticity of the material, and the high value indicates that the material can withstand large deformation without breaking before breaking, has good flexibility and impact resistance, and can adapt to different installation and use environments.

-

Cangzhou Yulong Steel Co., Ltd.

-

Terefone:

+86 13303177267 -

Imeri:

admin@ylsteelfittings.com

- Icyongereza

- Icyarabu

- Umutaliyani

- Icyesipanyoli

- Igiporutugali

- Ikidage

- kazakh

- Persian

- Ikigereki

- Igifaransa

- Ikirusiya

- Igipolonye

- Tayilande

- Indoneziya

- Abanya Vietnam

- Zulu

- Igikoreya

- Uzbek

- Oya

- Igiseribiya

- Malayika

- Ukraine

- Gujarati

- Igikerewole

- hausa

- hawaiian

- Igiheburayo

- Miao

- Hongiriya

- Isilande

- igbo

- irish

- Ikiyapani

- Javanese

- Kannada

- Khmer

- Rwanda

- Umunyafurika

- Ikinyalubaniya

- Amharic

- Ikinyarumeniya

- Azaribayijan

- Basque

- Biyelorusiya

- Ikibengali

- Bosiniya

- Buligariya

- Igikatalani

- Cebuano

- Ubushinwa

- Ubushinwa (Tayiwani)

- Corsican

- Igikorowasiya

- Ceki

- Danemark

- Esperanto

- Esitoniya

- Igifinilande

- Igifaransa

- Abagalatiya

- Jeworujiya

- Kurdish

- Kirigizisitani

- Igituntu

- Ikilatini

- Ikilatini

- Lituwaniya

- Luxembourgish

- Abanyamakedoniya

- Malgashi

- Malayalam

- Maltese

- Maori

- Marathi

- Mongoliya

- Miyanimari

- Nepali

- Noruveje

- Noruveje

- Occitan

- Pashto

- Ikidage

- Punjabi

- Ikinyarumaniya

- Samoan

- Abanya-Gaelic

- Icyongereza

- Shona

- Sindhi

- Sinhala

- Igisilovaki

- Igisiloveniya

- Somaliya

- Sundanese

- Igiswahiri

- Igisuwede

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Turukiya

- Abanyaturukiya

- Urdu

- Uighur

- Welsh

- Ubufasha

- Yiddish

- Yoruba

Andika ubutumwa bwawe hano hanyuma utwohereze

Related News

-

Jul . 23, 2025Space-Saving Connection Mastery: How 1/2 Pipe Nipple’s 50mm Short Design Solves Dense Piping Installation Challenges?In the labyrinth of industrial machinery, where pipes weave through 200mm-wide gaps and every millimeter counts, the battle against cramped spaces often stalls projects.

-

Jul . 23, 2025Shale Gas Extraction Impact Resistance: How ASME B16.47 Flange's Hub-Thickened Design Passes Seismic Testing?In the high-stakes realm of shale gas extraction, where seismic activity and operational vibrations threaten pipeline integrity, the ASME B16.47 flange emerges as a critical safeguard.