-

Cangzhou Yulong Steel Co., Ltd.

-

Phone:

+86 13303177267 -

Email:

admin@ylsteelfittings.com

- English

- Arabic

- Italian

- Spanish

- Portuguese

- German

- kazakh

- Persian

- Greek

- French

- Russian

- Polish

- Thai

- Indonesian

- Vietnamese

- Zulu

- Korean

- Uzbek

- Hindi

- Serbian

- Malay

- Ukrainian

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Miao

- Hungarian

- Icelandic

- igbo

- irish

- Japanese

- Javanese

- Kannada

- Khmer

- Rwandese

- Afrikaans

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Esperanto

- Estonian

- Finnish

- Frisian

- Galician

- Georgian

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Dutch

- Punjabi

- Romanian

- Samoan

- Scottish Gaelic

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Turkish

- Turkmen

- Urdu

- Uighur

- Welsh

- Bantu

- Yiddish

- Yoruba

Dic . 04, 2024 06:34 Back to list

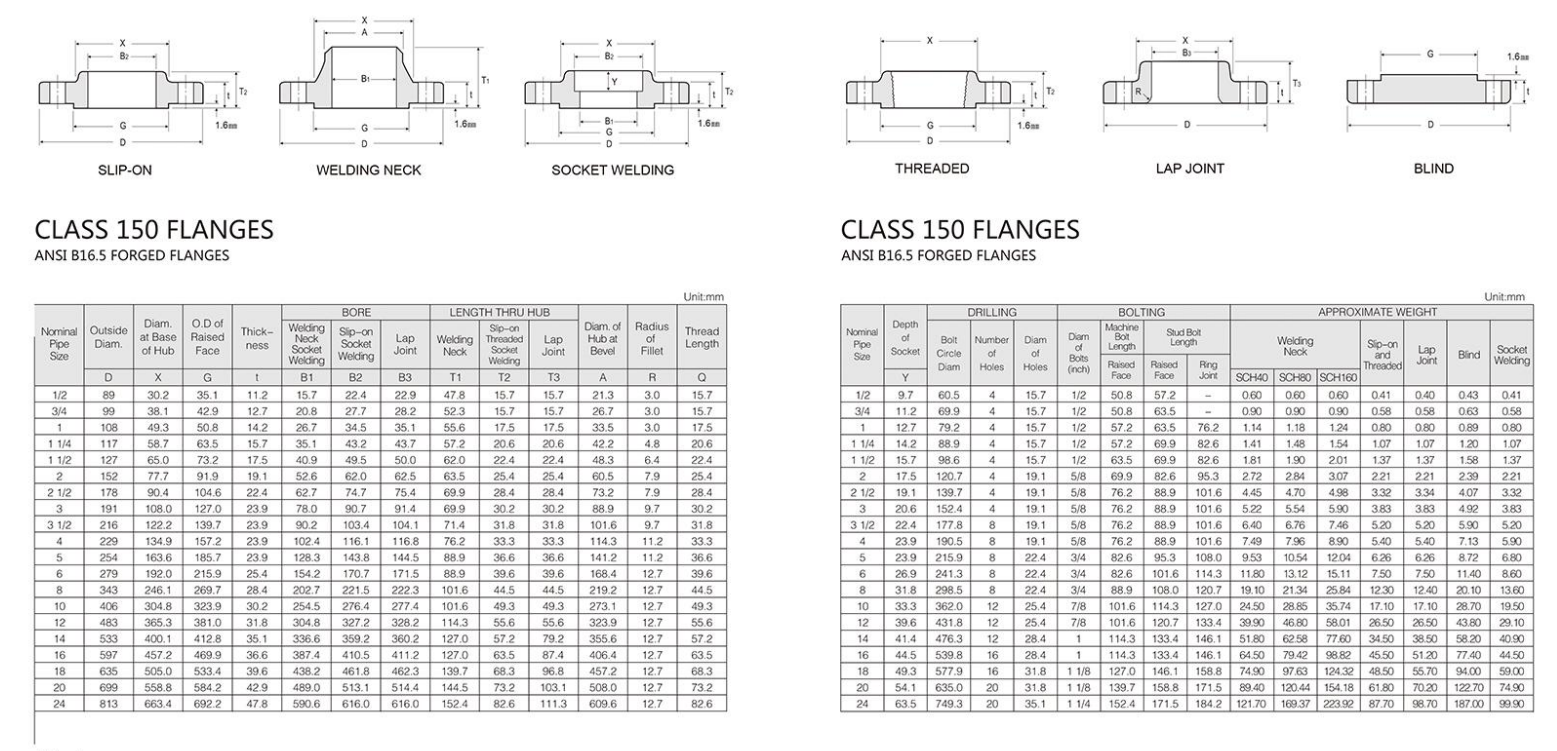

Understanding ANSI 150 Flat Face Flanges Specifications and Applications

Understanding ANSI 150 Flange Specifications and Their Applications

Flanges are essential components in piping systems, providing the means to connect pipes, valves, pumps, and other equipment. The ANSI (American National Standards Institute) standard for flanges outlines specific dimensions, tolerances, and materials to ensure compatibility and reliability in various industrial applications. Among these standards, the ANSI 150 flange, particularly the flat face (FF) version, plays a vital role in many systems.

What is ANSI 150 FF Flange?

The ANSI 150 flange refers to a type of pipe flange that conforms to a pressure rating of 150 pounds per square inch (psi). These flanges are widely used in piping systems that handle water, oil, and gas at relatively low pressures. The flat face designation indicates that the flange's face is flat rather than raised, which is crucial for certain applications. Flat face flanges are designed to sit flush against the connecting flange, providing an even surface for sealing.

Specifications and Dimensions

Nomenclature surrounding ANSI 150 flanges can be intricate, as various standards exist to classify flanges based on pressure ratings, size, and material. For ANSI 150 FF flanges, the dimensions are standardized in the ASME B16.5 specification. Common sizes range from ½ inch to 24 inches in diameter, making them versatile for numerous applications.

In terms of thickness, the flange varies according to its diameter and pressure rating. For example, a 1-inch ANSI 150 FF flange typically has a thickness of about 0.25 inches, whereas a 12-inch flange can be as thick as 0.75 inches. The bolt holes in these flanges are standardized as well, ensuring that they can be easily assembled with standard bolts and nuts.

Material Selection

The material of an ANSI 150 FF flange is critical, as it must withstand the specific operational environment. Common materials include carbon steel, stainless steel, and forged steel, each offering different mechanical properties and resistance to corrosion. For instance, carbon steel is often chosen for its strength and durability, while stainless steel is preferred in corrosive environments due to its excellent resistance to rust and oxidation.

flange ansi 150 ff

Applications of ANSI 150 Flanges

ANSI 150 FF flanges are found in various industries, including water treatment, chemical processing, and oil and gas. Their ability to maintain a secure seal and withstand operational stresses makes them ideal for piping systems. Moreover, their flat face design allows for easy installation and helps to distribute pressure evenly across the flange surface, reducing the risk of leaks.

In water treatment facilities, these flanges can be utilized in piping systems that transport potable water or sewage. The flat face design minimizes the risk of contamination, which is crucial in maintaining water quality standards. Similarly, in the chemical industry, ANSI 150 flanges are employed in processes requiring different chemical solutions, where material compatibility is essential.

Installation and Maintenance

Proper installation of ANSI 150 FF flanges is crucial to prevent leaks and ensure system integrity. It is essential to use the correct gasket material, typically non-metallic, to provide an effective seal between the flanges. The appropriate torque must be applied to the bolts to achieve the necessary compression without over-tightening, which could warp the flange or damage the gasket.

Regular maintenance checks are also vital. Inspections should focus on detecting any signs of corrosion, leaks, or wear. If any damage is found, prompt repair or replacement is necessary to ensure continued safe operation.

Conclusion

In summary, ANSI 150 FF flanges are crucial in various piping applications, offering reliable connections in low-pressure systems. Their standardized dimensions, material options, and flat face design make them versatile and essential components in many industries. Whether in water treatment, chemical processing, or oil and gas, understanding the specifications and applications of ANSI 150 flanges is vital for ensuring efficient and safe operations. Proper installation and maintenance practices will further enhance the longevity and performance of these critical components.

Latest news

-

ANSI 150P SS304 SO FLANGE

NewsFeb.14,2025

-

ASTM A333GR6 STEEL PIPE

NewsJan.20,2025

-

ANSI B16.5 WELDING NECK FLANGE

NewsJan.15,2026

-

ANSI B16.5 SLIP-ON FLANGE

NewsApr.19,2024

-

SABS 1123 FLANGE

NewsJan.15,2025

-

DIN86044 PLATE FLANGE

NewsApr.19,2024

-

DIN2527 BLIND FLANGE

NewsApr.12,2024

-

JIS B2311 Butt-Welding Fittings LR/SR 45°/90° /180°Seamless/Weld

NewsApr.23,2024