-

Cumplimiento del estándar DIN2527:

Las bridas ciegas DIN2527 cumplen con las especificaciones descritas por el Deutsches Institut für Normung (DIN), lo que garantiza uniformidad y compatibilidad con otros componentes que cumplen con DIN. Esta estandarización simplifica la integración de bridas ciegas en sistemas de tuberías, promoviendo una operación y mantenimiento perfectos. - Cierre sellado:

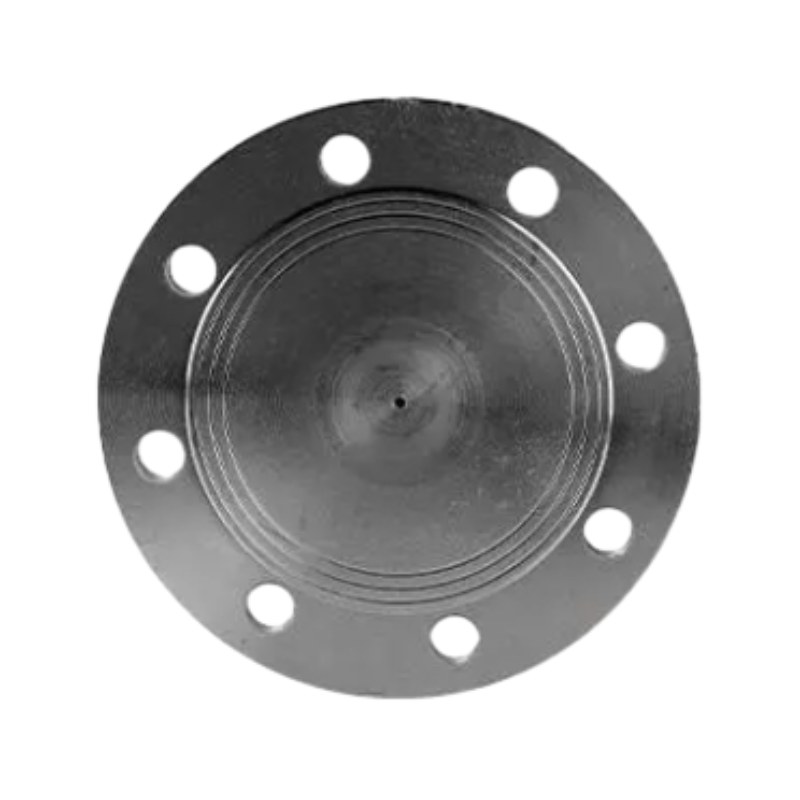

Las bridas ciegas cumplen la función esencial de sellar extremos de tuberías o aberturas en un sistema de tuberías. Las bridas ciegas DIN2527 cuentan con un disco plano y sólido con orificios para pernos alrededor del perímetro, lo que permite atornillarlas de forma segura a la brida correspondiente o al extremo de la tubería. Este cierre sellado evita la fuga de fluidos o gases, manteniendo la integridad y seguridad del sistema de tuberías. -

Aplicaciones versátiles:

Las bridas ciegas DIN2527 encuentran aplicación en diversas industrias, incluidas las de petróleo y gas, procesamiento químico, tratamiento de agua, generación de energía y construcción naval. Se utilizan en tuberías, recipientes a presión y tanques de almacenamiento para bloquear aberturas temporales o no utilizadas, aislar secciones de tuberías para mantenimiento o reparación, o como medio de inspección y prueba. -

Selección de materiales:

Las bridas ciegas están disponibles en varios materiales para adaptarse a diferentes condiciones de funcionamiento y medios. Los materiales comunes incluyen acero al carbono, acero inoxidable, acero aleado y aleaciones no ferrosas como latón o bronce. La elección del material depende de factores como la temperatura, la presión, la resistencia a la corrosión y la compatibilidad con el fluido o gas que se manipula. -

Clasificaciones de presión:

Las bridas ciegas DIN2527 están diseñadas para soportar presiones nominales específicas, que van desde PN6 a PN100, según las normas DIN. La clasificación de presión dicta la presión máxima permitida que la brida puede soportar de manera segura sin comprometer su integridad estructural o su rendimiento de sellado. Es esencial seleccionar bridas ciegas con la presión nominal adecuada para la aplicación prevista para garantizar un funcionamiento seguro y confiable. -

Opciones de personalización:

While DIN2527 blind flanges conform to standard dimensions and specifications, customization options are available to accommodate unique project requirements. This may include variations in flange size, facing type (such as flat face or raised face), bolt-hole pattern, and special coatings or treatments for enhanced corrosion resistance. Customized blind flanges are often tailored to fit specific piping configurations and operating conditions.

What Is a Blind Flange?

A blind flange is a solid, circular plate used to seal off the ends of piping systems, valves, or pressure vessels. Unlike other different flange types, blind flanges lack a central bore, making them ideal for completely closing off a pipeline or opening. They are commonly utilized in various industrial applications, including oil and gas, chemical processing, water treatment, and power generation, where secure and leak-proof pipe closures are essential.

Blind flanges are available in a wide range of sizes and pressure ratings, conforming to industry standards such as ANSI, ASME, and DIN. Sizes range from small diameters, like a 2-inch blind flange, to larger options, such as 36 blind flanges, catering to diverse operational requirements. The design typically features bolt holes around the perimeter, allowing the flange to be securely fastened to a mating component, like a pipe flange or valve.

The primary purpose of a blind flange is to isolate sections of a pipeline for maintenance, testing, or system modifications without disrupting the entire operation. They also play a critical role in pressure testing, allowing operators to evaluate the system's capacity under specific conditions.

Materials for blind flanges include stainless steel, carbon steel, alloy steel, and other metals, ensuring compatibility with various operating environments, including high-temperature, high-pressure, or corrosive conditions. Some blind flanges also feature coatings or linings for additional durability.

Blind flanges are essential for ensuring safety, system integrity, and operational flexibility. Their robust design and adaptability make them indispensable in industrial piping systems, providing reliable sealing solutions and enhancing overall efficiency.

What Is a Blind Flange Used For

Pipeline Isolation

Blind flanges are commonly used to isolate sections of a pipeline for maintenance, repairs, or system upgrades. By sealing off the pipeline, operators can work on specific sections without interrupting the entire operation.

System Testing

In pressure testing scenarios, blind flanges enable operators to assess the strength and performance of the pipeline or vessel under controlled conditions. The flange helps maintain pressure within the system during testing, ensuring accurate results.

Future Expansion

Blind flanges can be installed at pipeline terminations where future expansions are anticipated. They temporarily seal the system, allowing additional components to be integrated later without significant modifications.

Safety in Shutdowns

During system shutdowns, blind flanges ensure that no residual fluids or gases escape, enhancing safety for maintenance crews and protecting the environment.

Preventing Contamination

In industries like food processing or pharmaceuticals, blind flanges are used to prevent contamination by securely sealing unused pipeline sections.

Blind Flange Types

Standard Blind Flanges

Standard blind flanges are flat, solid discs with no central bore. They are designed to fit a variety of piping systems and are often categorized by standards such as ANSI, ASME, and DIN. These flanges are versatile and used in applications with moderate pressure and temperature conditions.

Raised Face (RF) Blind Flanges

Raised face blind flanges feature a slightly elevated sealing surface. The raised face provides a better seal when paired with gaskets, making them suitable for higher-pressure applications in industries like oil and gas.

Flat Face (FF) Blind Flanges

Flat-face blind flanges have a uniform sealing surface that lies flush with the pipe flange. They are ideal for systems where flange surfaces must be evenly distributed to prevent damage, such as in low-pressure environments.

Ring-Type Joint (RTJ) Blind Flanges

RTJ blind flanges feature a grooved surface to accommodate metal gaskets. This design provides superior sealing, making them ideal for high-pressure and high-temperature systems, such as petrochemical plants.

Threaded Blind Flanges

Threaded blind flanges have threads on their inner surface, allowing them to be screwed directly onto a threaded pipe. They are commonly used in low-pressure systems and applications requiring quick assembly and disassembly.

DIN 2527 Blind Flange Advantages

The DIN 2527 blind flange is an essential component in piping systems, particularly in industrial applications where robust sealing is required. This type of flange offers several advantages, making it a preferred choice for many engineers and designers.

Firstly, one of the main benefits of the DIN 2527 blind flange is its ability to provide a secure and leak-proof seal. By covering the ends of pipes, it effectively blocks the flow, preventing any unwanted leaks or exposures. This is particularly critical in systems that transport hazardous materials, where safety and environmental protection are of utmost importance.

Secondly, the DIN 2527 blind flange is designed to withstand high pressure and temperature conditions, which ensures durability and long service life. Constructed from various materials, including stainless steel, carbon steel, and alloys, these flanges can be tailored to meet specific operational requirements, enhancing their reliability under extreme conditions.

Another advantage is the easy installation process. The blind flange can be easily bolted to the end of a pipe without requiring any special tools or complex techniques. This simplifies the assembly process and allows for quicker maintenance or modifications in the future.

Additionally, blind flanges are highly versatile and can be used in a range of applications, from oil and gas to water treatment and chemical processing. This versatility makes the DIN 2527 blind flange an excellent solution for diverse industries.

Moreover, using blind flanges can enhance the system's overall design by facilitating future expansions or modifications. Since they can be removed and replaced without extensive alterations to the piping layout, they provide flexibility in system management.

In summary, the DIN 2527 blind flange offers secure sealing, durability, ease of installation, versatility, and design flexibility, making it a vital component in many industrial piping systems. Its advantages contribute significantly to operational efficiency and safety, solidifying its status as a preferred choice in various applications.

Las bridas ciegas DIN2527 son componentes indispensables en los sistemas de tuberías y proporcionan un cierre confiable y a prueba de fugas para extremos o aberturas de tuberías. Su cumplimiento de los estándares DIN, su versatilidad y sus opciones personalizables los hacen adecuados para una amplia gama de aplicaciones industriales donde el sellado hermético y la contención de presión son fundamentales. Con las bridas ciegas DIN2527, los ingenieros y operadores pueden garantizar la integridad, la seguridad y la eficiencia de sus sistemas de tuberías, contribuyendo a operaciones fluidas y sin problemas en todas las industrias.