-

Conexión segura:

Os acoplamentos roscados están deseñados para crear unha conexión segura e estanca entre dous tubos ou accesorios roscados. Presentan roscas internas en ambos os extremos, o que lles permite enroscar nas roscas externas dos tubos ou accesorios. Unha vez apretado, o acoplamento forma unha unión robusta que evita fugas e asegura o fluxo de fluído ou gas sen interrupción.

-

Aplicacións versátiles:

Os acoplamentos de rosca atopan aplicacións nunha ampla gama de industrias, incluíndo fontanería, HVAC (calefacción, ventilación e aire acondicionado), irrigación e sistemas de tuberías industriais. Utilízanse para conectar tubos, válvulas e accesorios en ambientes residenciais, comerciais e industriais, proporcionando unha solución cómoda e eficiente para unir compoñentes roscados.

-

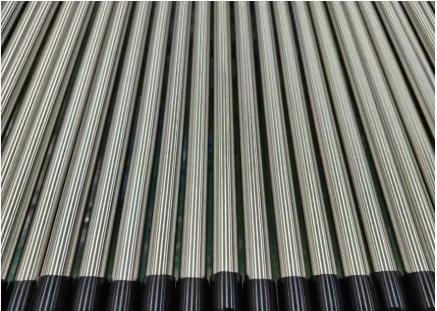

Selección de material:

Os acoplamentos de rosca están dispoñibles en varios materiais para adaptarse a diferentes condicións de funcionamento e medios. Os materiais comúns inclúen latón, aceiro inoxidable, aceiro carbono e PVC (cloruro de polivinilo). A elección do material depende de factores como a resistencia á corrosión, o índice de presión, a temperatura e a compatibilidade co fluído que se transporta.

-

Facilidade de instalación:

Unha das principais vantaxes dos acoplamentos de rosca é a súa facilidade de instalación. Pódense atornillar de xeito rápido e sinxelo en tubos ou accesorios roscados utilizando ferramentas básicas como chaves inglesas ou chaves para tubos. Esta sinxeleza na instalación reduce os custos laborais e o tempo de inactividade, facendo que os acoplamentos de rosca sexan unha opción preferida para reparacións, mantemento e instalacións de fontanería.

-

Selo a proba de fugas:

Os acoplamentos de rosca están deseñados para crear un selado a proba de fugas entre os compoñentes conectados. As roscas do acoplamento enganchan coas roscas dos tubos ou accesorios, creando unha conexión estanca e segura que impide que o fluído ou o gas escape. A instalación e o axuste adecuados do acoplamento garanten un selado fiable que resiste a presión e mantén a integridade ao longo do tempo.

-

Compatibilidade:

Os acoplamentos de rosca están dispoñibles en varios tamaños e estándares de rosca para garantir a compatibilidade con diferentes diámetros de tubos e tipos de rosca. Os estándares de roscas comúns inclúen NPT (National Pipe Thread), BSP (British Standard Pipe) e roscas métricas. É esencial seleccionar acoplamentos que coincidan co tamaño de rosca e o tipo dos tubos ou accesorios que se conectan para garantir un axuste e selado axeitados.

Os acoplamentos roscados son accesorios indispensables nos sistemas de fontanería e tubaxes industriais, que ofrecen unha solución sinxela pero eficaz para unir compoñentes roscados de forma segura. A súa conexión segura, versatilidade, facilidade de instalación, selado a proba de fugas, opcións de materiais e compatibilidade convértenos en compoñentes esenciais en varias aplicacións nas que se requiren conexións de tubos fiables. Cos acoplamentos de rosca, os profesionais e os entusiastas do bricolaxe poden conseguir instalacións de tubaxes eficientes e duradeiras, garantindo un funcionamento suave e sen problemas dos sistemas de fontanería.

Coupling Thread Types

In the world of piping and plumbing, coupling threads play an essential role in ensuring seamless connections between pipes. Different types of coupling threads are designed for specific applications, and comprehending these types can greatly enhance the functionality and performance of any piping system. One common variant is the 3-inch threaded coupling, which is widely used across various industries.

What are Coupling Threads?

Coupling threads refer to the helical grooves formed on the exterior of a coupling, which allow two pipes to be securely joined. The design and specifications of these threads can vary significantly based on the materials involved and the intended purpose of the connection. Understanding these variations is vital for selecting the right type of coupling for your project.

Types of Coupling Threads

There are several primary types of coupling threads, including NPT (National Pipe Thread), BSP (British Standard Pipe), and metric threads. Each type has distinct characteristics that make them suitable for different environments.

1. NPT Threads: National Pipe Tapered threads are commonly used in the United States. They have a taper that ensures a tightly sealed connection as the threads engage with one another. The 3-inch threaded coupling is often available in this thread type, which is ideal for applications requiring a strong gas or liquid seal.

2. BSP Threads: British Standard Pipe threads are widely used in the UK and other countries. These threads are designed with a different taper and are often found in water and gas lines. Like NPT, 3-inch BSP threaded couplings are also available, catering to various industry requirements.

3. Metric Threads: These threads are defined by their diameter in millimeters and are commonly used outside of North America. Thread specifications can vary, making it imperative to ensure compatibility when working with international piping systems.

Threaded Coupling Dimensions

| Diameter | Thread Type/Standard | Material | Length | Applications |

| 1/4" (1/4-20) | UNC/UNF | Stainless Steel | 1–4" | Small machinery, electronics |

| 3/8" (3/8-24) | NPT, BSP | Carbon Steel | 2–6" | Plumbing, automotive |

| 1/2" | NPT, BSPT | Brass, ABS | 2–8" | Water lines, gas systems |

| 3/4" | NPT, BSPP | Hot-Dip Galvanized | 3–12" | Industrial piping, HVAC |

| 1 1/2" | NPT, BSPT | ABS, PVC | 4–16" | Drainage, chemical systems |

| 2" | ANSI B1.20.1 | Carbon Steel | 6–24" | Heavy-duty construction, oil/gas |

| 2 1/2" | NPT | Stainless Steel | 8–24" | Marine, high-pressure pipelines |

| 4" | BSPP | Hot-Dip Galvanized | 12–36" | Sewage, large-scale infrastructure |

| 6" | ANSI B16.11 | Carbon Steel | 24–48" | Petrochemical plants |

| Metric Sizes | ||||

| 10mm | M10×1.5 | Aluminum | 20–80mm | Precision equipment |

| 20mm | M20×2.5 | Stainless Steel | 50–200mm | Machinery, robotics |

| 32mm | BSPP | Brass | 100–300mm | Hydraulic systems |

| 40mm | Solvent Weld | PVC | 150–400mm | Irrigation, wastewater |

| 50mm | BSPT | Hot-Dip Galvanized | 200–500mm | Structural frameworks |

Key Features & Variations

All-Thread Couplings: Available for 1/4", 3/8", 5/8", and 3/4" rods (lengths customizable).

Solvent Weld Options: 40mm PVC couplings for leak-proof chemical resistance.

Hot-Dip Galvanized: ASTM A153-certified for corrosion-prone environments.

ABS/PVC Couplings: Lightweight, non-conductive solutions for electrical and plumbing systems.

Why Choose Yulong Threaded Couplings?

Precision Threading: CNC-machined threads ensure perfect alignment and sealing.

Bulk Pricing: Discounts on orders over 100 units.

Custom Sizes: Tailor-made couplings for unique industrial needs (e.g., 1.5", 8", M20).

Fast Global Shipping: Ready stock for 90% of listed sizes.

Explore our full range or [contact Yulong] for technical support!

Coupling Thread FAQs

Q1: What is a thread coupling, and what applications is it suitable for?

A1: A thread coupling is a mechanical component designed to connect two threaded components securely. It ensures a robust and reliable connection in various applications such as plumbing, piping systems, hydraulic systems, and in mechanical assemblies. Due to its versatility, it is commonly used in construction, manufacturing, and automotive industries. By providing a strong coupling solution it minimizes leakage or disconnection risks, making it ideal for both residential and industrial projects.

Q2: How do I know if this thread coupling is compatible with my existing equipment?

A2: To determine compatibility, you need to check the specifications of your existing equipment, including the thread size and type—such as NPT, BSPT, or metric threads. Our thread coupling is available in various sizes to ensure that you can find the right fit for your application. If you're still unsure, please consult the product datasheet or reach out to our customer service team for professional assistance in finding the perfect match for your needs.

Q3: What materials are used in your thread couplings, and are they durable?

A3: Our thread couplings are made from high-quality materials, including stainless steel, brass, and durable plastics, depending on the specific version you choose. Stainless steel and brass options offer exceptional corrosion resistance and superior strength, making them suitable for demanding environments. You can trust our thread couplings to provide a long-lasting and reliable connection, even under high-pressure conditions.

Q4: Are these thread couplings easy to install, or do I need professional help?

A4: Our thread couplings are designed for straightforward installation, allowing for quick connections without the need for specialized tools. With a simple thread connection, you can easily install them by hand or with standard tools, depending on the application. However, if you are unsure or are working on a complex system, we recommend consulting with a professional to ensure optimal performance and safety.

Q5: Do you offer warranties or guarantees on your thread couplings?

A5: Yes, we stand behind the quality of our thread couplings and offer a warranty that covers any manufacturing defects. If you experience any issues within the warranty period, we will gladly assist you with a replacement or refund. Customer satisfaction is our priority, and we are committed to ensuring you have a positive experience with our products. Feel confident in your purchase, knowing we support our customers long after the sale.