JIS B2311 é un estándar industrial xaponés que abarca accesorios para tubos de soldadura a tope, incluíndo tapas utilizadas nos sistemas de tubaxes. As tapas de soldadura a tope serven para pechar o extremo dun tubo, proporcionando un selado para evitar fugas ou contaminación. Aquí tes unha introdución ás tapas de soldadura a tope JIS B2311:

- 1. JIS B2311 Standard:

- - A norma JIS B2311 especifica os requisitos para o deseño, dimensións, materiais, fabricación e probas de accesorios de soldadura a tope, incluídas as tapas, nos sistemas de tubaxes.

- - A norma garante que as tapas producidas de acordo coas normas JIS cumpran os estándares de calidade e sexan compatibles con outros compoñentes de tubaxes.

- 2. Tapón de soldadura a tope:

- - Un tapón de soldadura a tope, segundo JIS B2311, é un accesorio deseñado para cubrir e selar o extremo dun tubo de forma segura, ofrecendo protección e mantendo a integridade do sistema de tubaxes.

- - Os tapóns utilízanse nas situacións nas que o extremo da tubaxe require o peche, de forma permanente ou temporal, para evitar fugas, contaminación ou para dar un acabado ao sistema.

- 3. Material e construción:

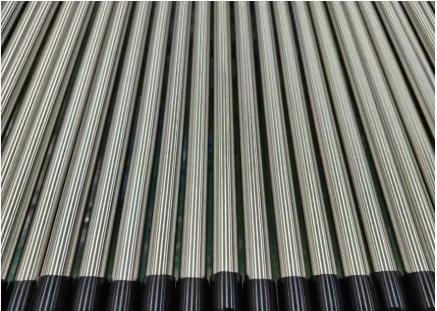

- - Os tapóns de soldadura a tope segundo as especificacións JIS B2311 están dispoñibles en varios materiais como aceiro carbono, aceiro inoxidable e aceiro de aliaxe para satisfacer diferentes requisitos de aplicación.

- - Estes tapóns están fabricados utilizando métodos de construción estandarizados para garantir unha conexión forte e sen fugas cando se soldan ao extremo dun tubo.

- 4. Aplicación e beneficios:

- - Os tapóns de soldadura a tope atopan aplicacións en varias industrias, incluíndo petróleo e gas, procesos químicos, plantas de tratamento de auga e moito máis, onde os extremos dos tubos deben ser tapados de forma segura.

- - Os tapóns proporcionan protección aos extremos das tubaxes dos elementos ambientais, evitan a contaminación e axudan a manter a limpeza e integridade do sistema de tubaxes.

- 5. Instalación e soldadura:

- - As prácticas de instalación adecuadas, incluíndo o aliñamento correcto, a preparación do extremo do tubo e as técnicas de soldadura, son esenciais á hora de instalar tapas de soldadura a tope para garantir un selado estanco e a proba de fugas.

- - A soldadura é un método común para unir tapas aos tubos, proporcionando un peche seguro e permanente que pode soportar presión, variacións de temperatura e fluxo de fluído dentro do sistema.

- En resumo, as tapas de soldadura a tope JIS B2311 son compoñentes cruciais utilizados nos sistemas de tubaxes para selar e protexer o extremo dos tubos de forma segura. Estes tapóns axústanse aos requisitos estandarizados para garantir a calidade, a fiabilidade e a compatibilidade nas aplicacións industriais onde sexan necesarios o peche e a protección de tubos.

What Is a Butt Welding Cap and How Is It Used in Industrial Piping?

In industrial piping systems, end-of-line sealing and branch closures require robust solutions. A butt welding cap serves as a critical component for terminating pipes securely. By providing a seamless, welded closure, this fitting maintains system integrity, prevents leaks, and supports compliance with industry standards.

What Is a Butt Welding Cap?

A butt welding cap—also called a pipe end cap or buttweld end cap—is a round fitting designed to close off the end of a pipe. It’s manufactured to match the pipe’s outer diameter and schedule, with either a hemispherical or flat face. To install, both the pipe end and cap are beveled to form a V‑groove, enabling full‑penetration, fusion welds. Common materials include carbon steel, stainless steel, nickel alloys, and other engineered grades, chosen to satisfy pressure, temperature, and corrosion‑resistance requirements.

How Is Butt Welding Cap Used in Industrial Piping?

Butt welding caps find application across oil & gas, petrochemical, power generation, water treatment, and general process industries for both permanent and temporary closures. During hydrostatic testing, technicians install caps to seal off sections of piping while monitoring for leaks. In new construction or retrofit projects, caps terminate branch lines, future tie‑in spools, or dead‑end mains until system expansion. Welders prepare each joint by cleaning and beveling surfaces, aligning the cap precisely, and executing a root pass followed by filler passes per the qualified Welding Procedure Specification (WPS). Post‑weld heat treatment and non‑destructive examination (NDE)—such as radiography or ultrasonic testing—verify weld integrity and compliance with ASME B16.9 and related standards. Additionally, temporary caps enable safe isolation during maintenance, allowing for segment testing and dewatering under regulatory protocols.

Benefits and Best Practices

Butt welding caps offer a smooth‑bore transition that minimizes flow disruption and stress concentration. Their full‑penetration welds deliver exceptional structural strength and leak resistance. To optimize performance, engineers should:

Select caps with matching material grades and wall thicknesses

Adhere to proper bevel angles and joint fit‑up tolerances

Follow qualified WPS protocols rigorously

Consider cladding or protective coatings in corrosive environments to extend service life

Regular inspection and thorough documentation ensure long‑term reliability and safe operation under demanding conditions.

Butt welding caps are indispensable components for achieving durable, leak‑proof pipe terminations in a wide range of industrial applications.

Butt Welding Cap FAQs

What is a butt welding cap?

|

What materials are commonly used?

|

What standards govern butt welding caps?

|

How are butt welding caps installed?

|

Where are butt welding caps typically used?

|

What are the advantages of threaded caps?

|