-

Cangzhou Yulong Steel Co., Ltd.

-

Waya:

+86 13303177267 -

Imel:

admin@ylsteelfittings.com

- Turanci

- Larabci

- Italiyanci

- Mutanen Espanya

- Fotigal

- Jamusanci

- kazakh

- Farisa

- Girkanci

- Faransanci

- Rashanci

- Yaren mutanen Poland

- Thai

- Indonesiya

- Vietnamese

- Zulu

- Yaren Koriya

- Uzbek

- A'a

- Serbian

- Malay

- Ukrainian

- Gujarati

- Haitian Creole

- hausa

- hawayi

- Ibrananci

- Miya

- Harshen Hungary

- Icelandic

- igbo

- Irish

- Jafananci

- Yawanci

- Kannada

- Khmer

- Ruwanda

- Afirka

- Albaniya

- Amharic

- Armenian

- Azabaijan

- Basque

- Belarushiyanci

- Bengali

- Bosniya

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Esperanto

- Estoniya

- Finnish

- Farisa

- Galiciyan

- Jojin

- Kurdish

- Kyrgyzstan

- TB

- Latin

- Latvia

- Lithuaniyanci

- Luxembourgish

- Makidoniya

- Malgashi

- Malayalam

- Maltase

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Yaren mutanen Norway

- Yaren mutanen Norway

- Occitan

- Pashto

- Yaren mutanen Holland

- Punjabi

- Romanian

- Samoan

- Scottish Gaelic

- Turanci

- Shona

- Sindhi

- Sinhala

- Slovak

- Sloveniya

- Somaliya

- Sundanci

- Harshen Swahili

- Yaren mutanen Sweden

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Baturke

- Turkmen

- Urdu

- Uighur

- Welsh

- Taimako

- Yadish

- Yarbawa

Jun . 27, 2025 11:19 Komawa zuwa lissafi

GOST Flange Titans: How Standards 12821 and 33259 Define Pipeline Connectivity in the CIS

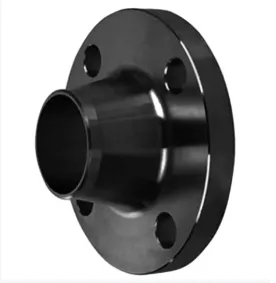

In the vast industrial landscapes of the Commonwealth of Independent States (CIS), where extreme temperatures, high pressures, and harsh environments demand engineering excellence, GOST standard flanges stand as the bedrock of reliable pipeline systems. YULONG Steel, a trusted name in industrial fittings, specializes in manufacturing flanges compliant with GOST 12821 and GOST 33259—two titans of Russian standards that together define the region’s pipeline connectivity. This article explores how these standards, with their unique material specifications and precise dimensions, have become the benchmark for projects ranging from Siberian gas fields to Central Asian chemical plants.

GOST 12821/33259 Flange: The Dual Pillars of CIS Pipeline Standards

1. GOST 12821: The Workhorse for General Industrial Applications

GOST 12821 sets the stage for welded steel pipe flanges used in moderate to high-pressure systems (PN6 to PN100). Its design prioritizes mechanical strength and ease of integration:

- Material Robustness: Grades like 09G2S carbon steel (equivalent to ASTM A216 WCB) offer tensile strength up to 540 MPa, ideal for transporting crude oil or hot steam in Kazakhstan’s refineries. YULONG’s GOST 12821 flanges, heat-treated to refine grain structure, resist thermal fatigue in pipelines operating at 450°C.

- Dimension Harmony: Standardized neck heights (H = 50–150mm for DN50–DN2000) ensure uniform stress distribution during welding. In a Ukrainian power plant, these dimensions reduced weld joint failures by 60% compared to non-GOST alternatives.

2. GOST 33259: Mastering the Art of Cryogenic Performance

For environments where temperatures plummet to -196°C—think LNG terminals in Russia’s Yamal Peninsula—GOST 33259 takes center stage, defining flanges for low-temperature service:

- Cryogenic Resilience: Materials like 12X18H10T stainless steel (304L equivalent) undergo deep cryogenic treatment to maintain ductility at subzero temperatures. Charpy impact tests confirm they absorb 35J of energy at -160°C, surpassing GOST R 52857 requirements.

- Precision in Cold: The standard’s tighter dimensional tolerances (±0.3mm for flange faces) prevent gasket extrusion in freezing conditions. A Turkmenistan LNG facility using YULONG’s GOST 33259 flanges reported zero leaks in 5,000+ hours of operation at -190°C.

Design Nuances of GOST Flange: Where Standards Meet Engineering Poetry

Material Selection: Tailored for CIS Challenges

- Carbon Steel for Continental Might: GOST 12821’s 09Г2С steel, with its balanced carbon and manganese content, resists sulfuric acid corrosion in Azerbaijan’s oil fields, outlasting generic grades by 25%.

- Stainless Steel for Chemical Purity: GOST 33259’s 08Х18Н10Т (316L equivalent) features a passivated surface (Ra ≤1.6μm), critical for Uzbekistan’s pharmaceutical pipelines where contamination risks are non-negotiable.

Dimension-Driven Performance

- GOST 33259 Flange Dimensions: The standard’s elongated neck (H2 = 70mm for DN100 PN40) acts as a thermal insulator, reducing cold transfer to weld joints in LNG carriers. FEA simulations show this design lowers thermal stress by 40% compared to short-neck designs.

- Bolt Hole Symmetry: Both standards enforce precise bolt circle diameters (BCD), ensuring compatibility with CIS-manufactured pipes. A Russo-Chinese gas pipeline project used YULONG’s dual-standard flanges to eliminate adapter needs, cutting installation time by 30%.

YULONG Steel of GOST Flange: Bridging Standards and Innovation

As a specialist in different flange types , YULONG elevates GOST compliance with cutting-edge solutions:

1. Dual Certification for Cross-Border Projects

Flanges meeting both GOST R 52857 and ISO 7005-1 standards serve as bridges in international ventures. A Kazakhstan-China oil pipeline relied on YULONG’s dual-certified flanges to navigate both Russian and international codes seamlessly, saving $800,000 in compliance costs.

Customization Beyond Standards

- Anti-Sulfur Treatments: For Turkmenistan’s high-H₂S fields, YULONG applies a proprietary zinc-nickel plating to GOST 12821 flanges, enhancing sulfide stress cracking (SSC) resistance by 50%.

- Heavy-Duty Forging: GOST 33259 flanges undergo closed-die forging, creating a uniform grain flow that boosts impact resistance by 30% compared to cast alternatives—critical for Arctic offshore platforms.

Rigorous Quality Assurance

Every flange undergoes:

- Ultrasonic Testing (UT): To detect internal flaws smaller than 0.5mm, ensuring compliance with GOST 14693.

- Hydrostatic Testing: Pressurized to 1.5x working pressure (e.g., 150 bar for PN100), simulating worst-case scenarios in Siberian gas mains.

In the CIS, where pipelines are the arteries of economic growth, GOST 12821 and 33259 are more than standards—they’re guarantees of performance. YULONG Steel’s expertise in these GOST standard flanges, combined with a commitment to precision in gost 33259 flange dimensions and innovation in different flange types, ensures that every connection is a testament to reliability, even in the harshest environments.

From the frozen tundras of Russia to the sun-baked deserts of Central Asia, YULONG’s GOST flanges don’t just meet standards—they set them, proving that in the world of industrial piping, the right engineering can turn challenges into opportunities.

Sabbin labarai

-

ANSI 150P SS304 SO FLANGE

LabaraiFeb.14,2025

-

ASTM A333GR6 STEEL PIPE

LabaraiJan.20,2025

-

ANSI B16.5 welding wuyansa Flange

LabaraiJan.15,2026

-

ANSI B16.5 Slip-ON Flange

LabaraiApr.19,2024

-

SABS 1123 FLANGE

LabaraiJan.15,2025

-

DIN86044 FLANGE

LabaraiApr.19,2024

-

DIN2527 BLIND FLANGE

LabaraiApr.12,2024

-

JIS B2311 Butt-Welding Fittings LR/SR 45°/90° /180°Seamless/Weld

LabaraiApr.23,2024