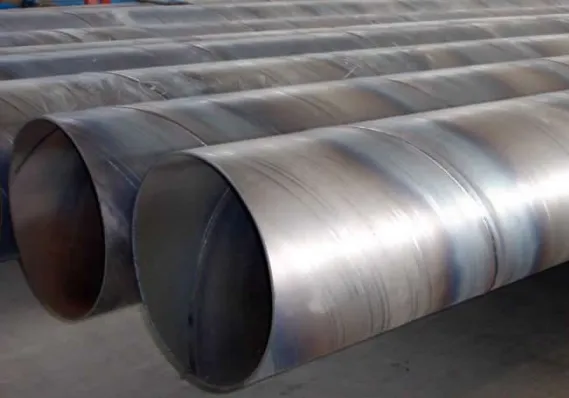

Steel Pipes - ASTM A252

| Specifications | Range |

| Out Diameter | 6.625"-16" |

| Wall Thickness | 0.188" - 0.688" |

ASTM A252 standard for specification for welded and seamless steel pipe piles.

This specification covers nominal wall cylindrical steel pipe piles in which the steel cylinder acts as a permanent load-carrying member or as a shell to form cast-in-place concrete piles. Each welded pile shall be made by seamless, electric resistance welding, flash welding or fusion welding with longitudinal, helical-butt, or helical-lap seams. This specification also deals with material tensile requirements, minimum elongation values and common size and weights per unit length values.

The finished pipe piles shall be reasonably straight and shall not contain imperfections in such number or of such character as to render the pipe unsuitable for pipe piles.

Surface imperfections, the depth of which does not exceed 25% of the nominal wall thickness, shall be permitted. These may be explored by grinding or filing to establish the depth.Surface imperfections, the depth of which exceeds 25% of the nominal wall thickness shall be considered defects. Repair of defects by welding will be permitted when the depth of defect does not exceed 33 ½ % of the nominal wall thickness. Before welding the defect shall be completely removed.

OD Tolerance: +/- 1%

WT Tolerance: - 12.5%

Min mechanical properties of ASTM A252

| Steel Grade | Tensile strength | Yield strength | Elongation |

| Grade A | 345 | 205 | 30 |

| Grade B | 414 | 240 | 25 |

| Grade C | 455 | 310 | 20 |