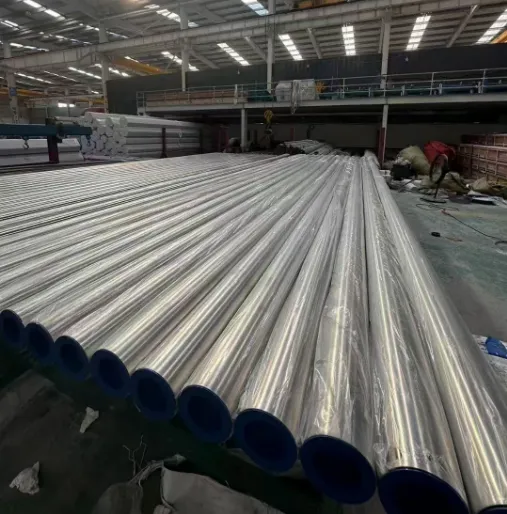

Steel Pipes - ASTM A632

|

|

ASTM A632 Standard Specification for Seamless and Welded Austenitic Stainless Steel Tubing (Small-Diameter) for General Service covers grades of stainless steel tubing for general corrosion-resisting and low or high-temperature service. The tubes shall be cold finished and shall be made by the seamless or welded process. All material shall be furnished in the heat-treatedcondition. The heat-treatment procedure shall consist of heating the material and quenching in water or rapidly cooling by other means. Tension tests, flaring tests, hydrostatic tests, air underwater pressure tests, and nondestructive electric tests shall be performed in accordance to the specified requirements.

1.1 This specification covers grades of stainless steel tubing in sizes under ½ down to 0.050 in. (12.7 to 1.27 mm) in outside diameter and wall thickness less than 0.065 in. down to 0.005 in. (1.65 to 0.13 mm) for general corrosion-resisting and low- or high-temperature service, as designated in Table 1.

Note 1—The grades of austenitic stainless steel tubing furnished in accordance with this specification have been found suitable for low-temperature service down to −325°F (−200°C) in which Charpy notched-bar impact values of 15 ft·lbf (20 J), minimum, are required and these grades need not be impact tested.

1.2 Optional supplementary requirements are provided and, when desired, shall be so stated in the order.

1.3 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.