-

Cangzhou Yulong Steel Co., Ltd.

-

Phone:

+86 13303177267 -

Email:

admin@ylsteelfittings.com

- English

- Arabic

- Italian

- Spanish

- Portuguese

- German

- kazakh

- Persian

- Greek

- French

- Russian

- Polish

- Thai

- Indonesian

- Vietnamese

- Zulu

- Korean

- Uzbek

- Hindi

- Serbian

- Malay

- Ukrainian

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Miao

- Hungarian

- Icelandic

- igbo

- irish

- Japanese

- Javanese

- Kannada

- Khmer

- Rwandese

- Afrikaans

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Esperanto

- Estonian

- Finnish

- Frisian

- Galician

- Georgian

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Dutch

- Punjabi

- Romanian

- Samoan

- Scottish Gaelic

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Turkish

- Turkmen

- Urdu

- Uighur

- Welsh

- Bantu

- Yiddish

- Yoruba

2월 . 19, 2025 09:09 Back to list

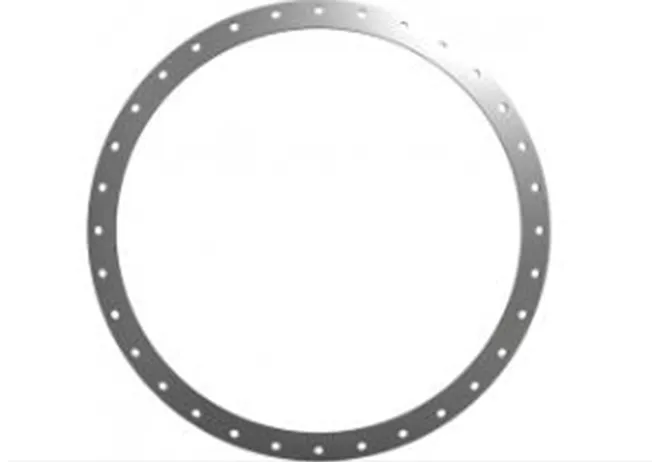

DIN2527 BLIND FLANGE

Navigating the complex world of DIN flange specifications can feel like an overwhelming task, especially for professionals seeking the ideal solution for their specific applications. DIN flanges, crafted following the Deutsches Institut für Normung (DIN) standards from Germany, are distinctive for their precision, durability, and adaptability across a myriad of industries. This exploration into DIN flange specifications offers an exceptional look tailored for experts and enterprises aspiring to bolster their application repertoire with unmatched quality and performance.

Specialized applications often necessitate specially designed DIN flanges. For instance, the DIN 2633 flange standard is commonly utilized in industries that require superior chemical resistance, such as food processing and marine environments, given its impeccable balance of operational capacity and robustness. Tailored designs such as these make DIN flanges a preferred choice for industry leaders aiming to maintain the highest standards of operational performance. Expert installation of DIN flanges can significantly enhance the lifespan and efficacy of the application. Professionals recommend procuring flanges that meet the precise specifications required by the project and pairing this with skilled installation practices. Ensuring all sealing surfaces are perfectly aligned, and using the appropriate gaskets and bolts, can minimize the risk of leaks or pressure loss, factors critical to maintaining the integrity of the entire assembly. Furthermore, ongoing maintenance and inspection of DIN flanges are imperative to ensure sustained performance and longevity. Regular checks for corrosion, wear and tear, and proper bolt tensioning can prevent system failures that could result in costly downtime or repairs. Implementing a thorough maintenance regime not only enhances product lifespan but also secures a reliable and safe operational environment, reaffirming trust with stakeholders and clients. In choosing DIN flanges, professionals align themselves with precision engineering excellence. These components, entrenched in tried and tested standards, bring unparalleled reliability to any industrial setup. An in-depth understanding and application of their specifications, coupled with expert installation and maintenance, underscore a commitment to quality and safety, key pillars in securing industry leadership and trustworthiness. Opting for DIN standards embodies not just a choice of component but a pledge towards operational excellence.

Specialized applications often necessitate specially designed DIN flanges. For instance, the DIN 2633 flange standard is commonly utilized in industries that require superior chemical resistance, such as food processing and marine environments, given its impeccable balance of operational capacity and robustness. Tailored designs such as these make DIN flanges a preferred choice for industry leaders aiming to maintain the highest standards of operational performance. Expert installation of DIN flanges can significantly enhance the lifespan and efficacy of the application. Professionals recommend procuring flanges that meet the precise specifications required by the project and pairing this with skilled installation practices. Ensuring all sealing surfaces are perfectly aligned, and using the appropriate gaskets and bolts, can minimize the risk of leaks or pressure loss, factors critical to maintaining the integrity of the entire assembly. Furthermore, ongoing maintenance and inspection of DIN flanges are imperative to ensure sustained performance and longevity. Regular checks for corrosion, wear and tear, and proper bolt tensioning can prevent system failures that could result in costly downtime or repairs. Implementing a thorough maintenance regime not only enhances product lifespan but also secures a reliable and safe operational environment, reaffirming trust with stakeholders and clients. In choosing DIN flanges, professionals align themselves with precision engineering excellence. These components, entrenched in tried and tested standards, bring unparalleled reliability to any industrial setup. An in-depth understanding and application of their specifications, coupled with expert installation and maintenance, underscore a commitment to quality and safety, key pillars in securing industry leadership and trustworthiness. Opting for DIN standards embodies not just a choice of component but a pledge towards operational excellence.

Next:

Latest news

-

ANSI 150P SS304 SO FLANGE

NewsFeb.14,2025

-

ASTM A333GR6 STEEL PIPE

NewsJan.20,2025

-

ANSI B16.5 WELDING NECK FLANGE

NewsJan.15,2026

-

ANSI B16.5 SLIP-ON FLANGE

NewsApr.19,2024

-

SABS 1123 FLANGE

NewsJan.15,2025

-

DIN86044 PLATE FLANGE

NewsApr.19,2024

-

DIN2527 BLIND FLANGE

NewsApr.12,2024

-

JIS B2311 Butt-Welding Fittings LR/SR 45°/90° /180°Seamless/Weld

NewsApr.23,2024