-

DIN2527 표준 준수:

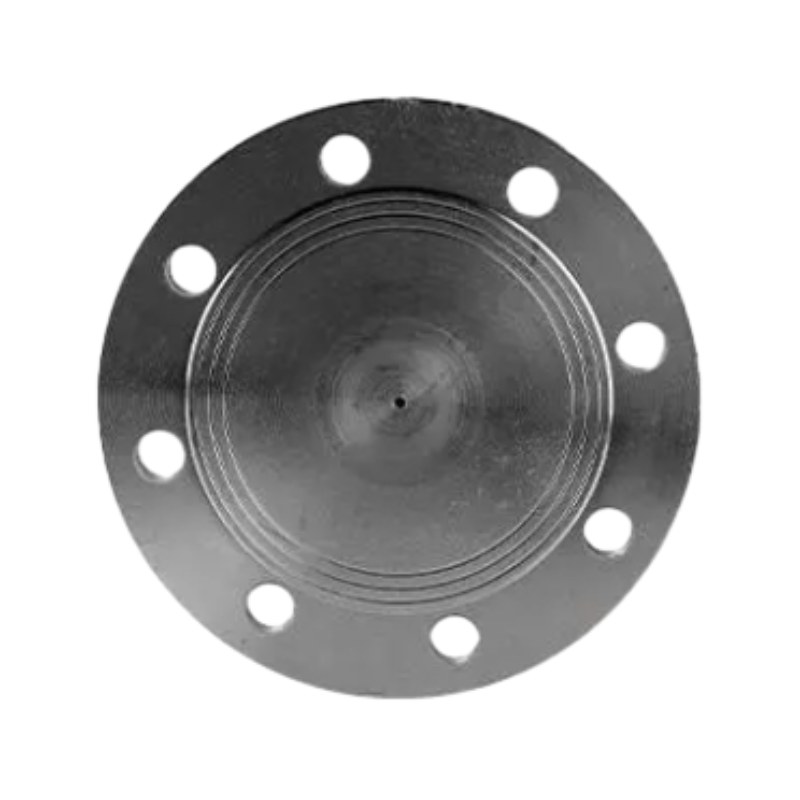

DIN2527 블라인드 플랜지는 DIN(Deutsches Institut für Normung)에서 설명한 사양을 준수하여 다른 DIN 호환 구성 요소와의 균일성과 호환성을 보장합니다. 이러한 표준화는 블라인드 플랜지를 배관 시스템에 통합하는 것을 단순화하여 원활한 작동 및 유지 관리를 촉진합니다. - 밀봉된 마감:

블라인드 플랜지는 배관 시스템의 파이프 끝이나 개구부를 밀봉하는 필수 기능을 제공합니다. DIN2527 블라인드 플랜지는 주변에 볼트 구멍이 있는 단단하고 평평한 디스크가 특징이므로 결합 플랜지나 파이프 끝에 볼트로 단단히 고정할 수 있습니다. 이 밀봉된 마개는 유체나 가스의 누출을 방지하여 배관 시스템의 무결성과 안전성을 유지합니다. -

다양한 용도:

DIN2527 블라인드 플랜지는 석유 및 가스, 화학 처리, 수처리, 발전 및 조선을 포함한 다양한 산업 분야에 적용됩니다. 파이프라인, 압력 용기 및 저장 탱크에서 사용되지 않거나 임시로 열리는 구멍을 막고, 유지 관리 또는 수리를 위해 배관 부분을 격리하거나 검사 및 테스트 수단으로 사용됩니다. -

재료 선택:

블라인드 플랜지는 다양한 작동 조건과 매체에 맞게 다양한 재질로 제공됩니다. 일반적인 재료에는 탄소강, 스테인리스강, 합금강, 황동이나 청동과 같은 비철 합금이 포함됩니다. 재료 선택은 온도, 압력, 내부식성, 취급하는 유체나 가스와의 호환성 등의 요소에 따라 달라집니다. -

압력 등급:

DIN2527 블라인드 플랜지는 DIN 표준에 따라 PN6에서 PN100까지의 특정 압력 등급을 견디도록 설계되었습니다. 압력 등급은 플랜지가 구조적 무결성이나 밀봉 성능을 손상시키지 않고 안전하게 견딜 수 있는 최대 허용 압력을 나타냅니다. 안전하고 안정적인 작동을 보장하려면 의도된 용도에 적합한 압력 등급을 갖춘 블라인드 플랜지를 선택하는 것이 중요합니다. -

사용자 정의 옵션:

While DIN2527 blind flanges conform to standard dimensions and specifications, customization options are available to accommodate unique project requirements. This may include variations in flange size, facing type (such as flat face or raised face), bolt-hole pattern, and special coatings or treatments for enhanced corrosion resistance. Customized blind flanges are often tailored to fit specific piping configurations and operating conditions.

What Is a Blind Flange?

A blind flange is a solid, circular plate used to seal off the ends of piping systems, valves, or pressure vessels. Unlike other different flange types, blind flanges lack a central bore, making them ideal for completely closing off a pipeline or opening. They are commonly utilized in various industrial applications, including oil and gas, chemical processing, water treatment, and power generation, where secure and leak-proof pipe closures are essential.

Blind flanges are available in a wide range of sizes and pressure ratings, conforming to industry standards such as ANSI, ASME, and DIN. Sizes range from small diameters, like a 2-inch blind flange, to larger options, such as 36 blind flanges, catering to diverse operational requirements. The design typically features bolt holes around the perimeter, allowing the flange to be securely fastened to a mating component, like a pipe flange or valve.

The primary purpose of a blind flange is to isolate sections of a pipeline for maintenance, testing, or system modifications without disrupting the entire operation. They also play a critical role in pressure testing, allowing operators to evaluate the system's capacity under specific conditions.

Materials for blind flanges include stainless steel, carbon steel, alloy steel, and other metals, ensuring compatibility with various operating environments, including high-temperature, high-pressure, or corrosive conditions. Some blind flanges also feature coatings or linings for additional durability.

Blind flanges are essential for ensuring safety, system integrity, and operational flexibility. Their robust design and adaptability make them indispensable in industrial piping systems, providing reliable sealing solutions and enhancing overall efficiency.

What Is a Blind Flange Used For

Pipeline Isolation

Blind flanges are commonly used to isolate sections of a pipeline for maintenance, repairs, or system upgrades. By sealing off the pipeline, operators can work on specific sections without interrupting the entire operation.

System Testing

In pressure testing scenarios, blind flanges enable operators to assess the strength and performance of the pipeline or vessel under controlled conditions. The flange helps maintain pressure within the system during testing, ensuring accurate results.

Future Expansion

Blind flanges can be installed at pipeline terminations where future expansions are anticipated. They temporarily seal the system, allowing additional components to be integrated later without significant modifications.

Safety in Shutdowns

During system shutdowns, blind flanges ensure that no residual fluids or gases escape, enhancing safety for maintenance crews and protecting the environment.

Preventing Contamination

In industries like food processing or pharmaceuticals, blind flanges are used to prevent contamination by securely sealing unused pipeline sections.

Blind Flange Types

Standard Blind Flanges

Standard blind flanges are flat, solid discs with no central bore. They are designed to fit a variety of piping systems and are often categorized by standards such as ANSI, ASME, and DIN. These flanges are versatile and used in applications with moderate pressure and temperature conditions.

Raised Face (RF) Blind Flanges

Raised face blind flanges feature a slightly elevated sealing surface. The raised face provides a better seal when paired with gaskets, making them suitable for higher-pressure applications in industries like oil and gas.

Flat Face (FF) Blind Flanges

Flat-face blind flanges have a uniform sealing surface that lies flush with the pipe flange. They are ideal for systems where flange surfaces must be evenly distributed to prevent damage, such as in low-pressure environments.

Ring-Type Joint (RTJ) Blind Flanges

RTJ blind flanges feature a grooved surface to accommodate metal gaskets. This design provides superior sealing, making them ideal for high-pressure and high-temperature systems, such as petrochemical plants.

Threaded Blind Flanges

Threaded blind flanges have threads on their inner surface, allowing them to be screwed directly onto a threaded pipe. They are commonly used in low-pressure systems and applications requiring quick assembly and disassembly.

DIN 2527 Blind Flange Advantages

The DIN 2527 blind flange is an essential component in piping systems, particularly in industrial applications where robust sealing is required. This type of flange offers several advantages, making it a preferred choice for many engineers and designers.

Firstly, one of the main benefits of the DIN 2527 blind flange is its ability to provide a secure and leak-proof seal. By covering the ends of pipes, it effectively blocks the flow, preventing any unwanted leaks or exposures. This is particularly critical in systems that transport hazardous materials, where safety and environmental protection are of utmost importance.

Secondly, the DIN 2527 blind flange is designed to withstand high pressure and temperature conditions, which ensures durability and long service life. Constructed from various materials, including stainless steel, carbon steel, and alloys, these flanges can be tailored to meet specific operational requirements, enhancing their reliability under extreme conditions.

Another advantage is the easy installation process. The blind flange can be easily bolted to the end of a pipe without requiring any special tools or complex techniques. This simplifies the assembly process and allows for quicker maintenance or modifications in the future.

Additionally, blind flanges are highly versatile and can be used in a range of applications, from oil and gas to water treatment and chemical processing. This versatility makes the DIN 2527 blind flange an excellent solution for diverse industries.

Moreover, using blind flanges can enhance the system's overall design by facilitating future expansions or modifications. Since they can be removed and replaced without extensive alterations to the piping layout, they provide flexibility in system management.

In summary, the DIN 2527 blind flange offers secure sealing, durability, ease of installation, versatility, and design flexibility, making it a vital component in many industrial piping systems. Its advantages contribute significantly to operational efficiency and safety, solidifying its status as a preferred choice in various applications.

DIN2527 블라인드 플랜지는 배관 시스템에 없어서는 안될 구성 요소로, 파이프 끝이나 개구부에 안정적이고 누출 방지 폐쇄 기능을 제공합니다. DIN 표준 준수, 다용성 및 사용자 정의 가능한 옵션 덕분에 견고한 밀봉 및 압력 억제가 중요한 광범위한 산업 응용 분야에 적합합니다. DIN2527 블라인드 플랜지를 사용하면 엔지니어와 운영자는 배관 시스템의 무결성, 안전성 및 효율성을 보장하여 산업 전반에 걸쳐 원활하고 문제 없는 운영에 기여할 수 있습니다.