-

Integral Verbindungskomponent:

BL flanges serve as integral connection components in piping systems, facilitating the assembly and disassembly of pipes, valves, and other equipment. These flanges feature a flat face with bolt holes around the perimeter, allowing for easy alignment and tightening of bolts to create a tight and secure joint.

-

Dichtungsfunktionalitéit:

D'Haaptfunktioun vun de BL-Flanges ass eng versiegelt Verbindung tëscht paréierende Komponenten ze kreéieren, d'Leckage vu Flëssegkeeten oder Gasen ze vermeiden. Wann richteg installéiert a bolted zesummen, Form BL Flanges eng zolidd a leck-proof Sigel, garantéiert d'Integritéit a Sécherheet vun der Päif System och ënner héijen Drock oder Temperatur Konditiounen.

-

Villsäiteg Uwendungen:

BL flanges find applications across a wide range of industries, including oil and gas, petrochemical, chemical processing, water treatment, and power generation. They are used in pipelines, pressure vessels, and equipment for connecting, terminating, or supporting piping systems, providing flexibility and adaptability in various industrial environments.

-

Material Auswiel:

BL Flanges sinn a verschiddene Materialien verfügbar fir verschidde Betribsbedéngungen a Medien ze passen. Gemeinsam Materialien enthalen Kuelestol, Edelstol, Legierungsstahl, an Net-ferro Legierungen wéi Messing oder Bronze. D'Wiel vum Material hänkt vu Faktoren of wéi Korrosiounsbeständegkeet, Temperatur, Drock a Kompatibilitéit mat der Flëssegkeet déi transportéiert gëtt.

-

Drock Bewäertungen:

BL Flanges sinn entwéckelt fir spezifesch Drockbewäertungen ze widderstoen, rangéiert vun der Klass 150 bis Klass 2500, ofhängeg vun der Gréisst, Material an Designnormen. Den Drockbewäertung weist de maximalen zulässlechen Drock un, deen de Flange sécher ka widderstoen ouni seng strukturell Integritéit oder Dichtungsleeschtung ze kompromittéieren, fir zouverlässeg Operatioun an usprochsvollen Ëmfeld ze garantéieren.

-

Personnalisatioun Optiounen:

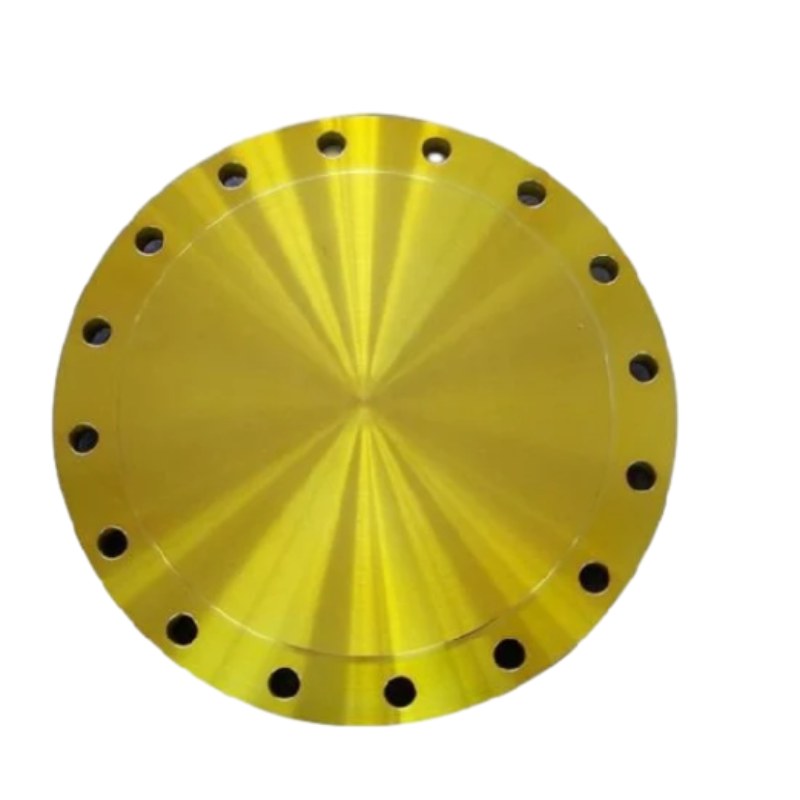

While BL flanges adhere to standard dimensions and specifications, customization options are available to meet specific project requirements. This may include variations in flange size, facing type (such as flat face or raised face), bolt-hole pattern, and special coatings or treatments for enhanced corrosion resistance. Customized BL flanges are often tailored to fit unique piping configurations and accommodate special conditions or operating environments.

What Is a Blind Flange?

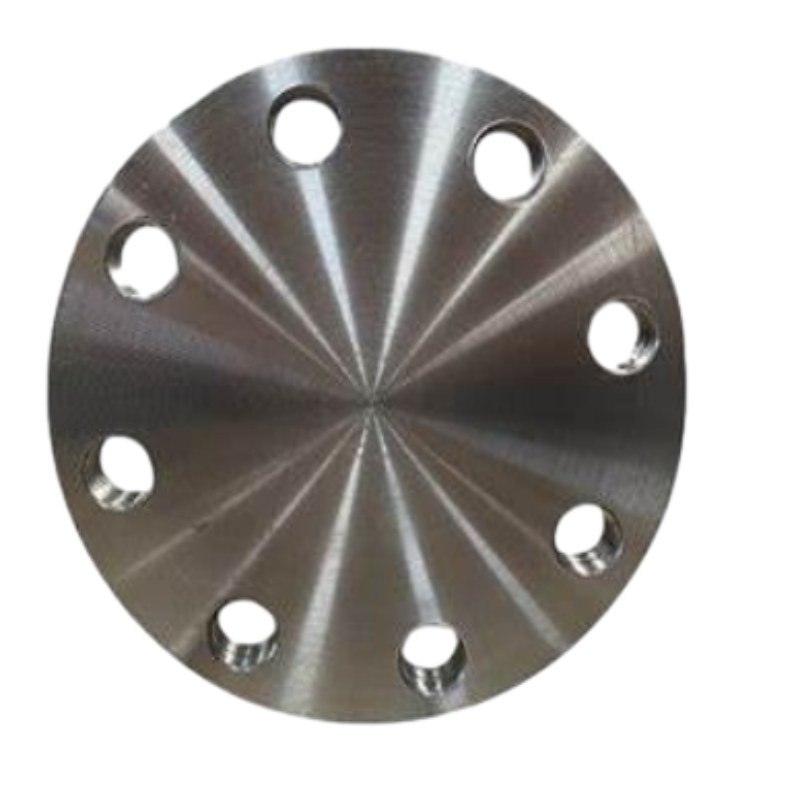

A blind flange is a type of flange used to seal the end of a pipe or a vessel. Unlike other flanges, which are designed to connect two sections of pipe, a blind flange is solid and does not have a hole in the center. This solid construction makes it an ideal solution for sealing the open ends of piping systems, preventing the flow of fluids or gases, and ensuring the integrity of the entire system.

Blind flanges are used in various industries, including oil and gas, chemical, water treatment, and power generation, where a temporary or permanent seal is needed for pipe ends, pressure vessels, or other equipment. They are available in different materials such as carbon steel, stainless steel, and alloy steel, allowing them to withstand various environmental conditions and pressures.

These flanges come in different sizes and dimensions to match the specific requirements of the piping system. They are typically designed to be bolted to the end of a pipe or vessel, using gaskets to ensure a tight, leak-proof seal. Blind flange types can vary based on the application and the pressure rating required, with options like raised face or flat face designs.

In addition to their sealing function, blind flanges also provide easy access to the interior of a pipeline or vessel for maintenance or inspection. Whether used in construction, industrial maintenance, or system upgrades, blind flanges play a critical role in ensuring the safety, performance, and longevity of piping systems.

Overall, blind flanges are a crucial component in pipe and vessel systems, offering versatility, reliability, and strength.

What Is a Blind Flange Used For

A blind flange is primarily used to seal the end of a pipe, vessel, or other equipment in a piping system. Unlike other flanges, which connect two sections of pipe, a blind flange is solid and does not have a central hole. This makes it an essential component in various applications where a temporary or permanent seal is required.

Blind flanges are commonly used to close off the ends of pipelines, pressure vessels, and tanks during construction, maintenance, or repair. They prevent the flow of fluids or gases, ensuring system integrity and safety. For example, in oil and gas operations, a blind flange may be used to close the end of a pipeline to prevent leaks while work is being carried out on another section of the system.

Another important use of blind flanges is for inspection and maintenance. They allow for easy access to the interior of a pipeline or vessel, enabling workers to inspect, clean, or replace parts as necessary without fully disassembling the system. This is particularly useful in industries like chemical, water treatment, and power generation, where downtime and repairs can be costly.

Blind flanges are also used in systems that require isolation or separation of fluids, ensuring that different sections of the system can be maintained independently. Their variety of materials, such as carbon steel, stainless steel, and alloy steel, makes them versatile and suitable for different environmental conditions and pressure ratings.

Overall, blind flanges are vital for sealing, isolating, and maintaining the functionality of piping and pressure systems.

Blind Flanges Types

Blind flanges come in several types, each designed to meet specific application needs, pressure ratings, and environmental conditions. The different types of blind flanges primarily vary in their design, facing style, and material construction. Here are the most common blind flange types used in the industry:

Flat Face Blind Flange

A flat-face blind flange has a flat sealing surface, which matches the flat face of the equipment it is attached to. This type is typically used in low-pressure applications, where the flange does not need to withstand extreme mechanical stresses. Flat face blind flanges are commonly used in systems with lower pressure ratings or where the sealing surface is flat, such as in some water treatment systems.

Raised Face Blind Flange

The raised face blind flange features a slightly raised portion around the sealing area, which enhances the sealing ability when paired with a gasket. The raised face creates a tighter seal under pressure, making it suitable for higher pressure systems. This is one of the most commonly used types in industries like oil and gas, chemical, and power generation, where strong, leak-proof seals are critical.

Ring Type Joint (RTJ) Blind Flange

A Ring Type Joint (RTJ) blind flange incorporates a recessed groove to accommodate a metal ring gasket, providing a high-pressure, leak-resistant seal. RTJ blind flanges are designed for use in extreme conditions, such as high-pressure systems or where heavy-duty sealing is required, often seen in the petrochemical and oil & gas sectors.

Weld Neck Blind Flange

A weld neck blind flange features a long neck that is welded to the pipe or vessel. This type provides excellent strength and is commonly used in systems that require a robust connection, especially in high-pressure and high-temperature environments. The welding neck design helps distribute the pressure more evenly, reducing the risk of leaks.

Slip-On Blind Flange

A slip-on blind flange is designed to slide over the pipe and then be welded in place. This type is easy to install and is often used in lower-pressure applications. It provides a good seal but may not be as durable as welded neck or RTJ flanges in high-stress situations.

Each type of blind flange serves a specific purpose, and choosing the right one depends on the pressure, temperature, and material compatibility required by the system.

BL flanges play a crucial role in piping systems, providing a secure and leak-proof connection between pipes or valves. Their integral functionality, sealing capabilities, versatile applications, and customization options make them indispensable in various industrial environments where reliable performance is essential. With BL flanges, engineers and operators can ensure the integrity, safety, and efficiency of their piping systems, contributing to smooth and trouble-free operations across industries.