-

DIN2527 Standard Konformitéit:

DIN2527 Blannflänzen hale sech un d'Spezifikatioune vum Deutsches Institut für Normung (DIN), fir d'Uniformitéit an d'Kompatibilitéit mat aneren DIN-konforme Komponenten ze garantéieren. Dës Standardiséierung vereinfacht d'Integratioun vu blann Flanges an Piping Systemer, fördert nahtlos Operatioun an Ënnerhalt. - Versiegelt Zoumaache:

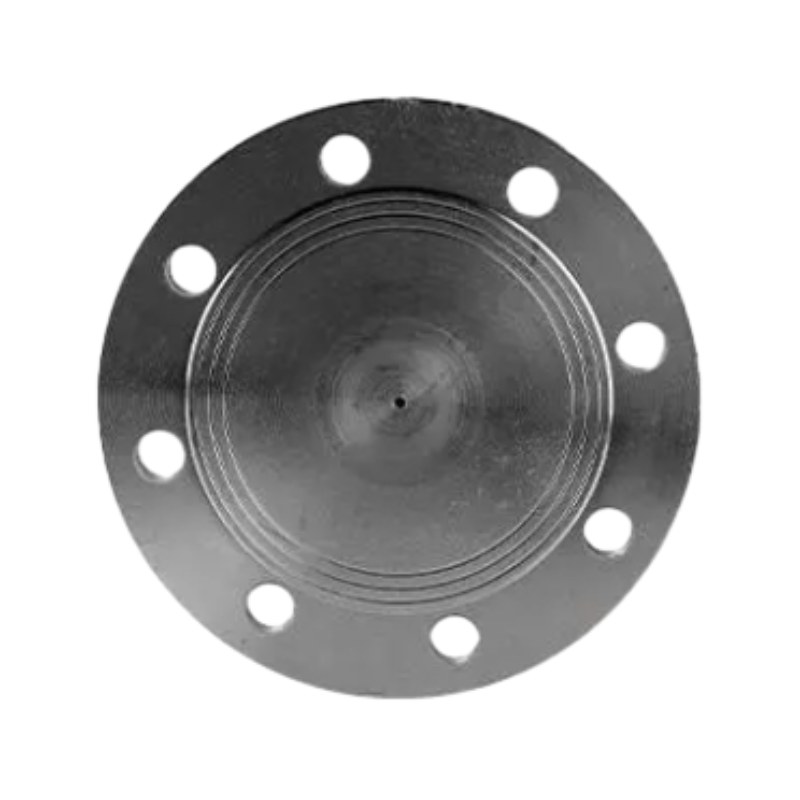

Blind Flanges déngen déi wesentlech Funktioun fir Päifen oder Ouverturen an engem Päifsystem ze versiegelen. DIN2527 Blannflenzen hunn eng zolidd, flaache Scheif mat Bolzenlächer ronderëm de Perimeter, wat et erlaabt datt se sécher an de passende Flange oder Pipeend bolten. Dës versiegelt Zoumaache verhënnert d'Leckage vu Flëssegkeeten oder Gasen, behält d'Integritéit an d'Sécherheet vum Pipesystem. -

Villsäiteg Uwendungen:

DIN2527 blann Flanges fannen Uwendung iwwer verschidden Industrien, dorënner Ueleg a Gas, chemesch Veraarbechtung, Waasserbehandlung, Kraaftproduktioun, a Schëffsbau. Si ginn a Pipelines, Drockbehälter a Späicherbehälter benotzt fir onbenotzt oder temporär Ëffnungen ze blockéieren, Sektioune vu Piping fir Ënnerhalt oder Reparatur ze isoléieren oder als Mëttel fir Inspektioun an Testen. -

Material Auswiel:

Blind Flanges sinn a verschiddene Materialien verfügbar fir verschidde Betribsbedéngungen a Medien ze passen. Gemeinsam Materialien enthalen Kuelestol, Edelstol, Legierungsstahl, an Net-ferro Legierungen wéi Messing oder Bronze. D'Wiel vum Material hänkt vu Faktoren of wéi Temperatur, Drock, Korrosiounsbeständegkeet a Kompatibilitéit mat der Flëssegkeet oder Gas déi gehandhabt gëtt. -

Drock Bewäertungen:

DIN2527 Blannflänzen sinn entwéckelt fir spezifesch Drockbewäertungen ze widderstoen, rangéiert vun PN6 bis PN100, no DIN Normen. Den Drockbewäertung diktéiert de maximal zulässlechen Drock, deen de Flange sécher widderstoen kann ouni seng strukturell Integritéit oder Dichtungsleeschtung ze kompromittéieren. Et ass essentiell fir blann Flanges mat dem passenden Drockbewäertung fir déi virgesinn Applikatioun ze wielen fir sécher an zouverlässeg Operatioun ze garantéieren. -

Personnalisatioun Optiounen:

While DIN2527 blind flanges conform to standard dimensions and specifications, customization options are available to accommodate unique project requirements. This may include variations in flange size, facing type (such as flat face or raised face), bolt-hole pattern, and special coatings or treatments for enhanced corrosion resistance. Customized blind flanges are often tailored to fit specific piping configurations and operating conditions.

What Is a Blind Flange?

A blind flange is a solid, circular plate used to seal off the ends of piping systems, valves, or pressure vessels. Unlike other different flange types, blind flanges lack a central bore, making them ideal for completely closing off a pipeline or opening. They are commonly utilized in various industrial applications, including oil and gas, chemical processing, water treatment, and power generation, where secure and leak-proof pipe closures are essential.

Blind flanges are available in a wide range of sizes and pressure ratings, conforming to industry standards such as ANSI, ASME, and DIN. Sizes range from small diameters, like a 2-inch blind flange, to larger options, such as 36 blind flanges, catering to diverse operational requirements. The design typically features bolt holes around the perimeter, allowing the flange to be securely fastened to a mating component, like a pipe flange or valve.

The primary purpose of a blind flange is to isolate sections of a pipeline for maintenance, testing, or system modifications without disrupting the entire operation. They also play a critical role in pressure testing, allowing operators to evaluate the system's capacity under specific conditions.

Materials for blind flanges include stainless steel, carbon steel, alloy steel, and other metals, ensuring compatibility with various operating environments, including high-temperature, high-pressure, or corrosive conditions. Some blind flanges also feature coatings or linings for additional durability.

Blind flanges are essential for ensuring safety, system integrity, and operational flexibility. Their robust design and adaptability make them indispensable in industrial piping systems, providing reliable sealing solutions and enhancing overall efficiency.

What Is a Blind Flange Used For

Pipeline Isolation

Blind flanges are commonly used to isolate sections of a pipeline for maintenance, repairs, or system upgrades. By sealing off the pipeline, operators can work on specific sections without interrupting the entire operation.

System Testing

In pressure testing scenarios, blind flanges enable operators to assess the strength and performance of the pipeline or vessel under controlled conditions. The flange helps maintain pressure within the system during testing, ensuring accurate results.

Future Expansion

Blind flanges can be installed at pipeline terminations where future expansions are anticipated. They temporarily seal the system, allowing additional components to be integrated later without significant modifications.

Safety in Shutdowns

During system shutdowns, blind flanges ensure that no residual fluids or gases escape, enhancing safety for maintenance crews and protecting the environment.

Preventing Contamination

In industries like food processing or pharmaceuticals, blind flanges are used to prevent contamination by securely sealing unused pipeline sections.

Blind Flange Types

Standard Blind Flanges

Standard blind flanges are flat, solid discs with no central bore. They are designed to fit a variety of piping systems and are often categorized by standards such as ANSI, ASME, and DIN. These flanges are versatile and used in applications with moderate pressure and temperature conditions.

Raised Face (RF) Blind Flanges

Raised face blind flanges feature a slightly elevated sealing surface. The raised face provides a better seal when paired with gaskets, making them suitable for higher-pressure applications in industries like oil and gas.

Flat Face (FF) Blind Flanges

Flat-face blind flanges have a uniform sealing surface that lies flush with the pipe flange. They are ideal for systems where flange surfaces must be evenly distributed to prevent damage, such as in low-pressure environments.

Ring-Type Joint (RTJ) Blind Flanges

RTJ blind flanges feature a grooved surface to accommodate metal gaskets. This design provides superior sealing, making them ideal for high-pressure and high-temperature systems, such as petrochemical plants.

Threaded Blind Flanges

Threaded blind flanges have threads on their inner surface, allowing them to be screwed directly onto a threaded pipe. They are commonly used in low-pressure systems and applications requiring quick assembly and disassembly.

DIN 2527 Blind Flange Advantages

The DIN 2527 blind flange is an essential component in piping systems, particularly in industrial applications where robust sealing is required. This type of flange offers several advantages, making it a preferred choice for many engineers and designers.

Firstly, one of the main benefits of the DIN 2527 blind flange is its ability to provide a secure and leak-proof seal. By covering the ends of pipes, it effectively blocks the flow, preventing any unwanted leaks or exposures. This is particularly critical in systems that transport hazardous materials, where safety and environmental protection are of utmost importance.

Secondly, the DIN 2527 blind flange is designed to withstand high pressure and temperature conditions, which ensures durability and long service life. Constructed from various materials, including stainless steel, carbon steel, and alloys, these flanges can be tailored to meet specific operational requirements, enhancing their reliability under extreme conditions.

Another advantage is the easy installation process. The blind flange can be easily bolted to the end of a pipe without requiring any special tools or complex techniques. This simplifies the assembly process and allows for quicker maintenance or modifications in the future.

Additionally, blind flanges are highly versatile and can be used in a range of applications, from oil and gas to water treatment and chemical processing. This versatility makes the DIN 2527 blind flange an excellent solution for diverse industries.

Moreover, using blind flanges can enhance the system's overall design by facilitating future expansions or modifications. Since they can be removed and replaced without extensive alterations to the piping layout, they provide flexibility in system management.

In summary, the DIN 2527 blind flange offers secure sealing, durability, ease of installation, versatility, and design flexibility, making it a vital component in many industrial piping systems. Its advantages contribute significantly to operational efficiency and safety, solidifying its status as a preferred choice in various applications.

DIN2527 Blannflänzen sinn onverzichtbar Komponenten a Päifsystemer, déi eng zouverlässeg a leckbeständeg Zoumaache fir Päifen oder Ouverturen ubidden. Hir Anhale un DIN Standarden, Villsäitegkeet an personaliséierbar Optiounen maachen se gëeegent fir eng breet Palette vun industriellen Uwendungen, wou enk Versiegelung an Drockbehälter kritesch sinn. Mat DIN2527 Blannflänzen kënnen d'Ingenieuren an d'Betreiber d'Integritéit, d'Sécherheet an d'Effizienz vun hire Päifsystemer garantéieren, bäidroe fir glat an problemfräi Operatiounen iwwer d'Industrie.