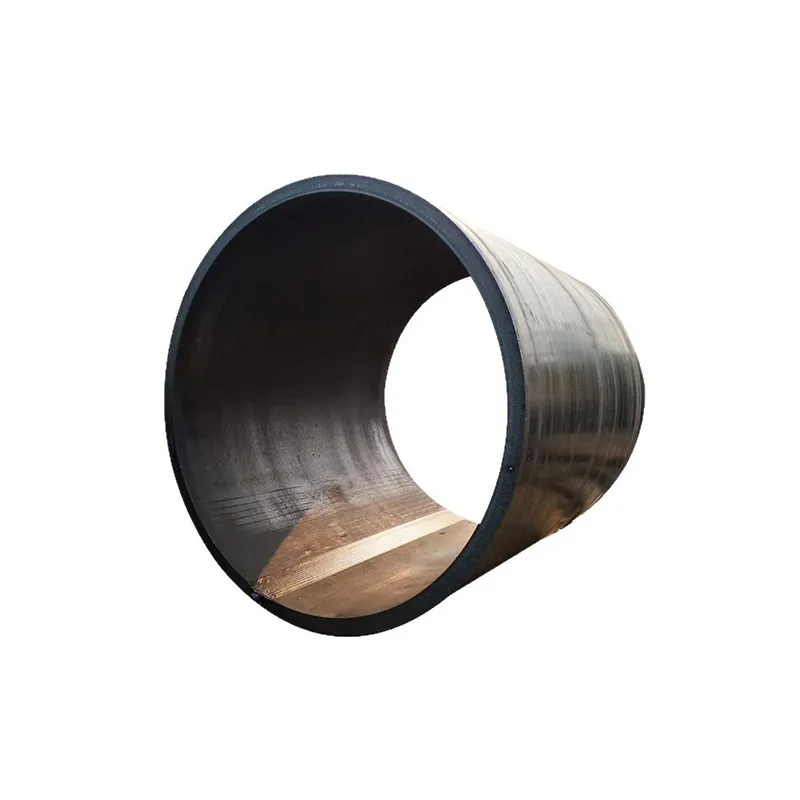

Double Submerged Arc Welded (DSAW) pipe is a premium steel pipe manufactured using an advanced welding process that ensures superior strength, durability, and reliability for high-pressure applications. The DSAW process involves forming steel plates into a cylindrical shape and welding both the inside and outside seams using submerged arc welding (SAW), resulting in a robust, uniform weld with excellent mechanical properties. Manufactured to API 5L, ASTM A252, EN 10219, and other international specifications to ensure quality and performance. DSAW pipe delivers unmatched reliability for critical infrastructure projects, combining advanced welding technology with high-grade steel for long-term performance.

1.Exceptional Strength & Durability: The double-sided welding process enhances structural integrity, making DSAW pipes ideal for high-pressure oil, gas, and water transmission systems.

2.Large Diameter Capability: Available in diameters ranging from 16" to over 100", DSAW pipes are perfect for major pipeline projects requiring wide-bore conduits.

3.Smooth Weld Seam: The submerged arc welding technique produces clean, defect-free welds with minimal internal roughness, improving flow efficiency.

4.Corrosion Resistance: Can be coated or lined for additional protection in corrosive environments, extending service life.

5.Versatile Applications: Suitable for onshore and offshore pipelines, structural piling, and industrial fluid transport.

|

Product Name |

Double Submerged Arc Welded Pipe |

|

Standard |

ASTMA53 Gr.B;API 5L:Gr.B,X42,X46,X52,X56,X60,X65,X70,X80 |

|

Welding Type |

Double Submerged Arc Welded |

|

Outer Diameter |

8"-64"(219.1mm-1626mm) |

|

Thickness |

SCH10-SCH160 (6.35mm-59.54mm) |

|

Length |

6m-18m |

|

End |

BE(Beveled Ends)PE(Plain Ends) |

|

Test |

Chemical Component Analysis,Mechanical Properties (Tensile strength |

|

Fastest Delivery Time |

7 Days for normal specification |

Yulong steel full of enthusiasm, has won a good reputation. Our staff members make every effort to make the Country prosperous. With excellent quality and perfect customer services, we have gained praise and high appreciation from clients from all over the world. We win a good reputation in the pipe export area every year. Our seamless steel pipes are unique products in China. These types of products make us stand in the top position all over the world.

Our main products: 1) Precision seamless steel pipes 2) Hot rolled seamless pipes 3) Cold drawn seamless pipes 4) SSAW steel pipes 5) LSAW steel pipes 6) ERW steel pipes 7)stainless steel pipe 8)seamless steel carbon pipe Our company has gained ISO9001 Quality system and API Certificates. We have been certified by the international PED TUV and National Special Equipment license. We are one of the qualified suppliers of Chinese Top Three Petroleum Companies and we have established long-term stable and strategic cooperative partnerships with many foreign well-known companies. Our sales network has covered almost around the world, such as South America, Europe, North America, the Middle East, Oceania, Africa, etc.

We adhere to the Management concept of "Quality first, Prestige first, Customer top" so as to provide the "First-class products and the First-class services" for all customers from all over the world. We would like to cooperate with worldwide customers for a Prosperous Future.