-

Cangzhou Yulong Steel Co., Ltd.

-

Phone:

+86 13303177267 -

Email:

admin@ylsteelfittings.com

- English

- Arabic

- Italian

- Spanish

- Portuguese

- German

- kazakh

- Persian

- Greek

- French

- Russian

- Polish

- Thai

- Indonesian

- Vietnamese

- Zulu

- Korean

- Uzbek

- Hindi

- Serbian

- Malay

- Ukrainian

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Miao

- Hungarian

- Icelandic

- igbo

- irish

- Japanese

- Javanese

- Kannada

- Khmer

- Rwandese

- Afrikaans

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Esperanto

- Estonian

- Finnish

- Frisian

- Galician

- Georgian

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Dutch

- Punjabi

- Romanian

- Samoan

- Scottish Gaelic

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Turkish

- Turkmen

- Urdu

- Uighur

- Welsh

- Bantu

- Yiddish

- Yoruba

Jan . 21, 2025 03:38 Back to list

api5lx52

API 5L X52 is one of the popular specifications set out by the American Petroleum Institute (API) for line pipe. It is especially utilized in the petroleum and natural gas industries. With its heightened requirements, API 5L X52 stands out due to its durability, versatility, and capabilities—making it essential for professionals serious about their infrastructure's performance.

Beyond industrial settings, the expertise and design of API 5L X52 also hold significance in environmental sustainability. As the global demand for efficient and eco-friendly energy transport solutions rises, API 5L X52 plays a crucial role in minimizing leaks and preventing potential ecological damage. This precision in manufacturing not only prevents resource wastage but also ensures adherence to environmental regulations, instilling confidence in stakeholders about the responsible practices of their operations. It is paramount for buyers to source API 5L X52 from trusted and certified manufacturers who uphold the integrity of the API standards. The trustworthiness of these manufacturers is often reflected in their history of compliance, production capabilities, and the satisfaction of existing clients—factors that are crucial when determining the right partner for pipeline projects. In summary, the API 5L X52 specification is more than a standard; it represents a commitment to quality and reliability. Its acclaimed use in various high-stake environments underscores its expertise and authority within the field. With consistent advancements in technology and material science, this specification continues to evolve, meeting the ever-changing demands of modern infrastructure, thereby shaping a future where safety, performance, and sustainability converge seamlessly.

Beyond industrial settings, the expertise and design of API 5L X52 also hold significance in environmental sustainability. As the global demand for efficient and eco-friendly energy transport solutions rises, API 5L X52 plays a crucial role in minimizing leaks and preventing potential ecological damage. This precision in manufacturing not only prevents resource wastage but also ensures adherence to environmental regulations, instilling confidence in stakeholders about the responsible practices of their operations. It is paramount for buyers to source API 5L X52 from trusted and certified manufacturers who uphold the integrity of the API standards. The trustworthiness of these manufacturers is often reflected in their history of compliance, production capabilities, and the satisfaction of existing clients—factors that are crucial when determining the right partner for pipeline projects. In summary, the API 5L X52 specification is more than a standard; it represents a commitment to quality and reliability. Its acclaimed use in various high-stake environments underscores its expertise and authority within the field. With consistent advancements in technology and material science, this specification continues to evolve, meeting the ever-changing demands of modern infrastructure, thereby shaping a future where safety, performance, and sustainability converge seamlessly.

Latest news

-

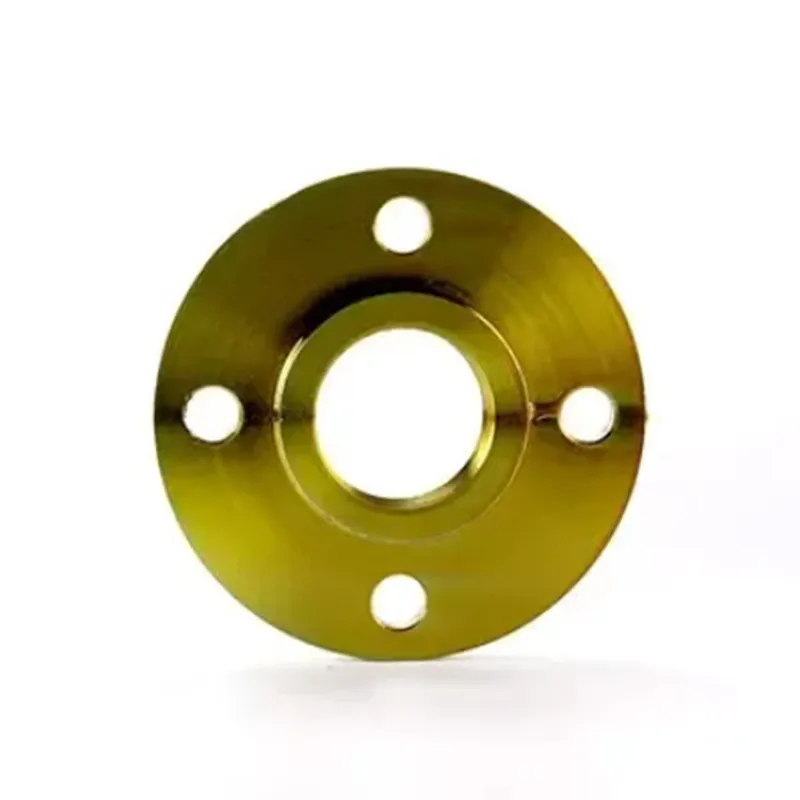

ANSI 150P SS304 SO FLANGE

NewsFeb.14,2025

-

ASTM A333GR6 STEEL PIPE

NewsJan.20,2025

-

ANSI B16.5 WELDING NECK FLANGE

NewsJan.15,2026

-

ANSI B16.5 SLIP-ON FLANGE

NewsApr.19,2024

-

SABS 1123 FLANGE

NewsJan.15,2025

-

DIN86044 PLATE FLANGE

NewsApr.19,2024

-

DIN2527 BLIND FLANGE

NewsApr.12,2024

-

JIS B2311 Butt-Welding Fittings LR/SR 45°/90° /180°Seamless/Weld

NewsApr.23,2024