-

Cangzhou Yulong Steel Co., Ltd.

-

Phone:

+86 13303177267 -

Email:

admin@ylsteelfittings.com

- English

- Arabic

- Italian

- Spanish

- Portuguese

- German

- kazakh

- Persian

- Greek

- French

- Russian

- Polish

- Thai

- Indonesian

- Vietnamese

- Zulu

- Korean

- Uzbek

- Hindi

- Serbian

- Malay

- Ukrainian

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Miao

- Hungarian

- Icelandic

- igbo

- irish

- Japanese

- Javanese

- Kannada

- Khmer

- Rwandese

- Afrikaans

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Esperanto

- Estonian

- Finnish

- Frisian

- Galician

- Georgian

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Dutch

- Punjabi

- Romanian

- Samoan

- Scottish Gaelic

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Turkish

- Turkmen

- Urdu

- Uighur

- Welsh

- Bantu

- Yiddish

- Yoruba

Jan . 21, 2025 04:00 Back to list

din 2527 flange dimensions

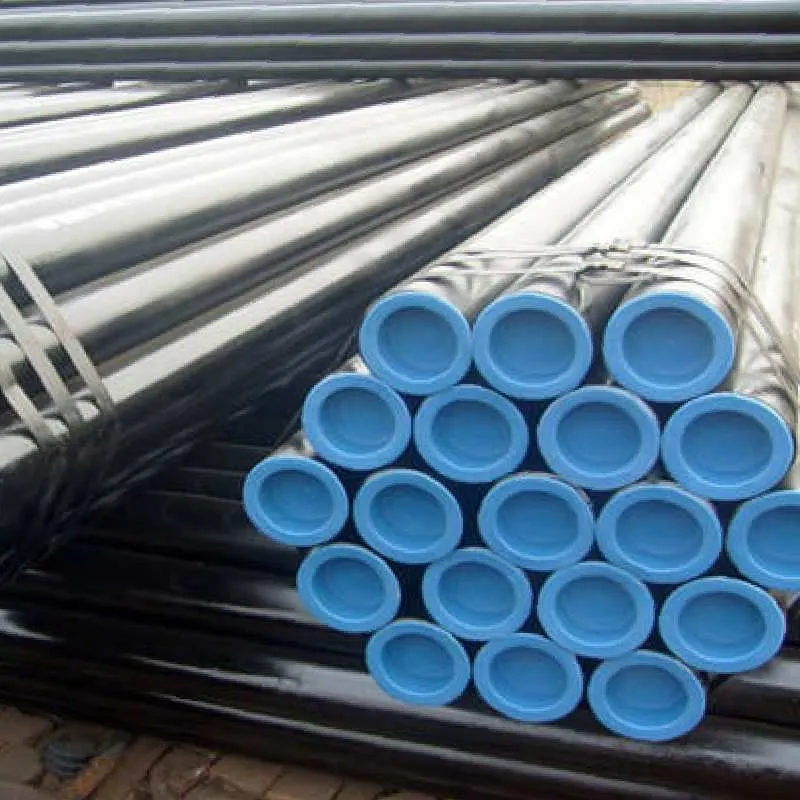

Steel pipes are integral components in various industries, particularly in construction, oil and gas, and energy. With an emphasis on durability, versatility, and pressure handling, EN 10216-1 pipes stand out due to their unique dimensions and precise specifications. The EN 10216-1 specification is quintessential for engineers and industry professionals seeking seamless steel tubes for pressure purposes.

Moreover, the expertise in developing these dimensions underlines the advancement of metallurgical processes. It illustrates a seamless blend of traditional steel manufacturing techniques with modern technological innovations. This integration not only refines the physical attributes of the pipes but also enhances their thermal performance capabilities. For professionals looking to source EN 10216-1 pipes, it is essential to engage with manufacturers who prioritize compliance with international standards. Manufacturers equipped with state-of-the-art facilities and experienced personnel guarantee pipe dimensions that facilitate secure and efficient installation and operation. When assembling or repairing high-pressure systems, the choice of correct pipe dimensions is critical. Selecting the right dimension of EN 10216-1 pipes ensures systems run smoothly, minimizes repair costs, and ensures safety. It avoids the operational hiccups often attributed to improper pipe sizing that can lead to system breakdowns or catastrophic accidents. In conclusion, EN 10216-1 pipe dimensions are a testament to engineering expertise and manufacturing excellence. Their robustness and practical design elevate their status as preferred choices in various demanding scenarios. Experts familiar with these dimensions can provide invaluable input in selecting pipes that are apt for specific applications, ensuring reliability and long-term functionality. Industries relying on high-pressure systems continue to trust EN 10216-1 pipes for their unwavering quality and performance. As the industry evolves, the focus on dimensions becomes more pronounced, reflecting the broader trend towards precision engineering and customized solutions. These pipes are more than just components; they represent the cutting edge of industrial applications, integrating efficiency, safety, and sustainability.

Moreover, the expertise in developing these dimensions underlines the advancement of metallurgical processes. It illustrates a seamless blend of traditional steel manufacturing techniques with modern technological innovations. This integration not only refines the physical attributes of the pipes but also enhances their thermal performance capabilities. For professionals looking to source EN 10216-1 pipes, it is essential to engage with manufacturers who prioritize compliance with international standards. Manufacturers equipped with state-of-the-art facilities and experienced personnel guarantee pipe dimensions that facilitate secure and efficient installation and operation. When assembling or repairing high-pressure systems, the choice of correct pipe dimensions is critical. Selecting the right dimension of EN 10216-1 pipes ensures systems run smoothly, minimizes repair costs, and ensures safety. It avoids the operational hiccups often attributed to improper pipe sizing that can lead to system breakdowns or catastrophic accidents. In conclusion, EN 10216-1 pipe dimensions are a testament to engineering expertise and manufacturing excellence. Their robustness and practical design elevate their status as preferred choices in various demanding scenarios. Experts familiar with these dimensions can provide invaluable input in selecting pipes that are apt for specific applications, ensuring reliability and long-term functionality. Industries relying on high-pressure systems continue to trust EN 10216-1 pipes for their unwavering quality and performance. As the industry evolves, the focus on dimensions becomes more pronounced, reflecting the broader trend towards precision engineering and customized solutions. These pipes are more than just components; they represent the cutting edge of industrial applications, integrating efficiency, safety, and sustainability.

Next:

Latest news

-

ANSI 150P SS304 SO FLANGE

NewsFeb.14,2025

-

ASTM A333GR6 STEEL PIPE

NewsJan.20,2025

-

ANSI B16.5 WELDING NECK FLANGE

NewsJan.15,2026

-

ANSI B16.5 SLIP-ON FLANGE

NewsApr.19,2024

-

SABS 1123 FLANGE

NewsJan.15,2025

-

DIN86044 PLATE FLANGE

NewsApr.19,2024

-

DIN2527 BLIND FLANGE

NewsApr.12,2024

-

JIS B2311 Butt-Welding Fittings LR/SR 45°/90° /180°Seamless/Weld

NewsApr.23,2024