-

Cangzhou Yulong Steel Co., Ltd.

-

Phone:

+86 13303177267 -

Email:

admin@ylsteelfittings.com

- English

- Arabic

- Italian

- Spanish

- Portuguese

- German

- kazakh

- Persian

- Greek

- French

- Russian

- Polish

- Thai

- Indonesian

- Vietnamese

- Zulu

- Korean

- Uzbek

- Hindi

- Serbian

- Malay

- Ukrainian

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Miao

- Hungarian

- Icelandic

- igbo

- irish

- Japanese

- Javanese

- Kannada

- Khmer

- Rwandese

- Afrikaans

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Esperanto

- Estonian

- Finnish

- Frisian

- Galician

- Georgian

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Dutch

- Punjabi

- Romanian

- Samoan

- Scottish Gaelic

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Turkish

- Turkmen

- Urdu

- Uighur

- Welsh

- Bantu

- Yiddish

- Yoruba

Dec . 03, 2024 11:25 Back to list

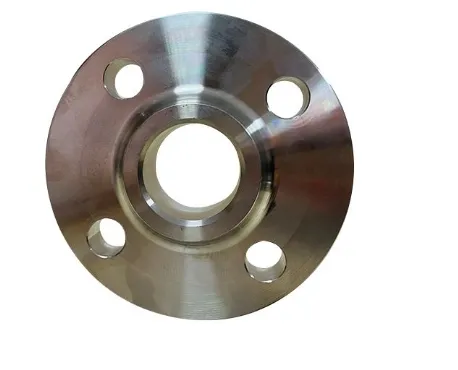

Comprehensive Guide to JIS B2220 Flanges: Standards, Dimensions, and Applications

JIS B2220 flanges are a cornerstone in piping systems, providing reliable connections in diverse industrial applications. Their adherence to the Japanese Industrial Standards (JIS) ensures compatibility, safety, and performance. This guide delves into their standards, dimensions, and applications to help engineers, designers, and procurement professionals make informed decisions.

Understanding JIS B2220 Standards

Flange jis b2220 10k the requirements for pipe flanges used in industrial systems. These standards focus on dimensional accuracy, material quality, and pressure class, ensuring uniformity and compatibility in manufacturing and installation. This precision is critical in industries where high-pressure and high-temperature conditions prevail, as improper specifications can lead to system failures.

The standards cover various flange types, including slip-on, socket weld, blind, and threaded flanges. Each type serves a specific function in connecting pipes, valves, or equipment. Jis b 2220 flanges are particularly notable for their metric-based dimensions, distinguishing them from standards like ANSI and DIN, which often use imperial measurements.

Key Dimensions of JIS B2220 Flanges

Dimensional accuracy is a hallmark of JIS B2220 flanges, with specifications covering flange diameter, bolt hole size, and thickness. These dimensions vary depending on the pressure rating, which ranges from 5K to 63K, where "K" represents kilopascal. Lower ratings are ideal for general-purpose applications, while higher ratings suit demanding environments like chemical processing and power generation.

The standards also define tolerances to ensure a proper seal when combined with gaskets. Proper alignment of bolt holes and flange faces is critical, as even slight deviations can compromise system integrity. Selecting the right size and pressure class is essential to match operational requirements and ensure long-term reliability.

Material Options for JIS B2220 Flanges

JIS B2220 flanges are manufactured from various materials to suit different applications. Carbon steel is commonly used for its strength and cost-effectiveness, while stainless steel offers superior resistance to corrosion and is ideal for industries like food processing and pharmaceuticals. For extreme conditions, materials like alloy steel or nickel alloys provide enhanced performance against high temperatures and aggressive chemicals.

Material selection also considers the environment where the flange will operate. For instance, marine applications demand corrosion-resistant materials like stainless steel or duplex alloys, while pipelines in arctic conditions may require low-temperature carbon steel to prevent brittleness.

Applications of JIS B2220 Flanges

JIS B2220 flanges find extensive use across industries due to their versatility and reliability. In the oil and gas sector, they are integral to pipelines, connecting critical components like valves and pumps. Their ability to withstand high-pressure environments ensures the safe transport of hydrocarbons over long distances.

In chemical and petrochemical industries, JIS B2220 flanges facilitate the movement of corrosive or hazardous substances. Their compatibility with specialized coatings and gaskets enhances their durability in such demanding conditions. Similarly, in power plants, these flanges are used in steam and cooling systems, where their high-temperature tolerance proves invaluable.

Water treatment plants and infrastructure projects also benefit from JIS B2220 flanges. Their standardized dimensions and pressure ratings simplify installation and maintenance, particularly in large-scale systems requiring seamless integration of multiple components.

Benefits of Choosing JIS B2220 Flanges

The advantages of JIS B2220 flanges extend beyond their technical specifications. Their compliance with international quality standards ensures reliability, making them a preferred choice for global projects. The availability of different materials and pressure classes offers flexibility in design, enabling their use in diverse environments.

Another key benefit is their ease of installation and maintenance. Precision manufacturing reduces the likelihood of misalignment during assembly, while their standardized design allows for straightforward replacement and repairs. This combination of features reduces downtime and overall maintenance costs, contributing to operational efficiency.

Latest news

-

ANSI 150P SS304 SO FLANGE

NewsFeb.14,2025

-

ASTM A333GR6 STEEL PIPE

NewsJan.20,2025

-

ANSI B16.5 WELDING NECK FLANGE

NewsJan.15,2026

-

ANSI B16.5 SLIP-ON FLANGE

NewsApr.19,2024

-

SABS 1123 FLANGE

NewsJan.15,2025

-

DIN86044 PLATE FLANGE

NewsApr.19,2024

-

DIN2527 BLIND FLANGE

NewsApr.12,2024

-

JIS B2311 Butt-Welding Fittings LR/SR 45°/90° /180°Seamless/Weld

NewsApr.23,2024