-

Cangzhou Yulong Steel Co., Ltd.

-

Phone:

+86 13303177267 -

Email:

admin@ylsteelfittings.com

- English

- Arabic

- Italian

- Spanish

- Portuguese

- German

- kazakh

- Persian

- Greek

- French

- Russian

- Polish

- Thai

- Indonesian

- Vietnamese

- Zulu

- Korean

- Uzbek

- Hindi

- Serbian

- Malay

- Ukrainian

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Miao

- Hungarian

- Icelandic

- igbo

- irish

- Japanese

- Javanese

- Kannada

- Khmer

- Rwandese

- Afrikaans

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Esperanto

- Estonian

- Finnish

- Frisian

- Galician

- Georgian

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Dutch

- Punjabi

- Romanian

- Samoan

- Scottish Gaelic

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Turkish

- Turkmen

- Urdu

- Uighur

- Welsh

- Bantu

- Yiddish

- Yoruba

Jul . 29, 2025 23:20 Back to list

High-Quality Plastic Coated Steel Pipe for Corrosion Resistance

A comprehensive insight into the latest Plastic coated steel pipe innovations, technology process, industry application, and market-leading solutions.

Official Product Page >Industry Overview & Trend Analysis

Plastic coated steel pipe—also referred to as PE/PVC lining steel pipe—has been at the forefront of corrosion-resistant piping for critical industries including petrochemicals, water treatment, fire protection, and metallurgy. According to a 2023 Frost & Sullivan report, the global market for plastic-coated pipes surpassed 3.6 million tons, with an expected CAGR of 6.2% from 2023-2028, driven by increasing demand for durable and maintenance-friendly pipeline systems.

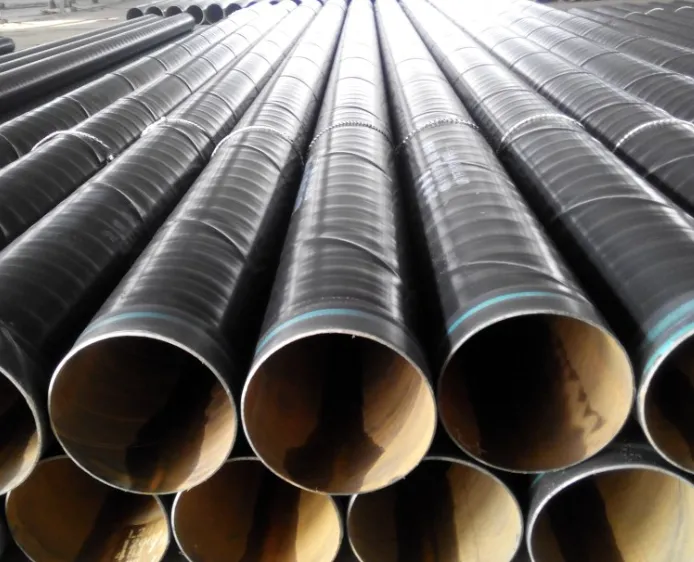

Figure 1. Modern Plastic coated steel pipe production facility

Figure 1. Modern Plastic coated steel pipe production facility

Technical Parameters & Third-party Standard Compliance

| Item | Parameter | Standard/Reference | Performance |

|---|---|---|---|

| Base Steel Grade | Q235B, S235JR, ASTM A53/106 B | GB/T 700, EN 10025, ASTM | Yield > 235 MPa |

| Coating Material | Polyethylene (PE), Polypropylene (PP), Epoxy, PVC | ISO 21809-3, ANSI C213 | Layer thickness 0.5–2.5mm |

| Pipe Diameter Range | DN15–DN2000 mm | EN 10220, ASME B36.10M | ±1.5mm tolerance |

| Working Pressure | PN6–PN32 | EN 1092-1, DIN 30670 | Leakage ≤ 0.1% |

| Temperature Range | -35°C to +85°C | ISO 4427 | Thermal expansion ≤ 1.2mm |

| Adhesion Strength | >7 N/mm | ISO 21809-3 | Grade 1-3 (highest) |

| Corrosion Resistance | >1000h in salt spray test | ASTM B117, ISO 9227 | No blistering, peeling |

| Service Life | Over 50 years | ISO/TR 10400 | Under standard use |

Manufacturing Process Flow — Plastic Coated Steel Pipe

The production of Plastic coated steel pipe integrates sophisticated metallurgy and polymer technology, ensuring superior adhesion, corrosion resistance, and mechanical strength. Below is a typical process flow:

(Base: Q235B/ASTM A53B)

Cutting, surface cleaning, blast finishing

At 180-220°C

Improves coating adhesion

- Fluidized bed PE/PVC/Epoxy dip

- Uniform thickness 0.8–2.5mm

Rapid convection air/water

Bonds polymer to steel

- Electrostatic pinhole test

- Adhesion (ISO 21809-3)

Anti-impact wrap, traceable code

For a detailed video demonstration, see: Plastic Coated Steel Pipe Manufacturing Video »

Key Technical Advantages of Plastic Coated Steel Pipe

- Superior Corrosion Resistance: Proven by >1,000h salt spray as per ASTM B117 and ISO 9227.

- Durable Mechanical Strength: Steel skeleton ensures PN6–PN32 operation, robust impact resistance far exceeding pure plastic pipes.

- Long Lifespan: Over 50 years under standard conditions; minimal maintenance frequency, validated by field projects since 2001.

- Hygienic Lining: Suitable for potable water (meets EN 10224, FDA & NSF standard), safe for direct drinking water supply.

- Cost-Effective Lifecycle: Lower total cost of ownership compared to stainless or fully lined systems, thanks to fewer replacements/repairs.

- Broad Adaptability: Flexible to all common flanges/joints, supports custom curves/coating types for harsh environments.

- Optional Add-ons: UV-resistant, chemical-specific coating, reinforced wall for high-pressure, fireproof, and anticorrosion classes.

Figure 2. Plastic coated steel pipe in municipal water supply network

Figure 2. Plastic coated steel pipe in municipal water supply network

Global Supplier & Product Comparison

| Brand/Supplier | Region | Main Standards Supported | Coating Type | Max DN (mm) | Warranty (Years) | Major Endusers |

|---|---|---|---|---|---|---|

| Yulong Steel | China | ISO, ANSI, DIN 30670 | PE, Epoxy, PVC | 2000 | 10 | Sinopec, local water utilities |

| Wienerberger | Europe | EN, ISO, FDA | Epoxy, Polyolefin | 1400 | 8 | Municipal, industrial water |

| Ameron Intl. | USA | ASTM, NSF61 | Fusion-bonded epoxy | 1800 | 12 | Petrochemical, mining |

| Nippon Steel | Japan | JIS, ISO, FDA | PE, Epoxy | 1600 | 10 | Fire, irrigation |

| Wuxi Huge | China | ISO, ANSI | Epoxy, PVC | 1200 | 7 | Building, refinery |

Tip: Plastic coated steel pipe costs vary (USD 14–36/meter) depending on coating thickness, service temperature, and volume.

Customization & Solution Consultation

Our engineering team delivers tailored Plastic coated steel pipe solutions meeting diverse project requirements:

- Diameter (DN15~DN2000 mm) support, customized wall thickness, and multicolor/graded coatings for easy maintenance management.

- On-demand ISO, ANSI, or FDA compliant products with full material/traceability records.

- Pre-fabricated bends/elbows, tees, reducers, joint packs for streamlined site installation.

- Integration service: pipe + fittings + coating + transport = one-stop delivery.

- On-site installation guidance and post-sales inspection support, with digital project documentation and QC traceability.

Typical Delivery Time: Stocked sizes: 3–7 days; Custom orders: 15–30 days by volume/spec.

Warranty: 8-12 years, with full replacement on material/quality defects.

Certifications: ISO 9001, ISO 14001, FDA (for potable water), and 20+ country access.

Application Scenarios & Case Studies

- Municipal Water Network: Over 138km of Plastic coated steel pipe supplied for Hangzhou city water supply (2019-2022). Failure rate <0.03%, water quality maintained above WHO potability standards.

- Petrochemical Pipeline: Yulong pipes selected by Sinopec Zhenhai for internal refinery process line, offering up to 45% longer replacement cycle versus bare steel (validated by TUV SUD audit, 2023).

- Fire Protection Systems: Bulk supplies to Fosun Pharma’s new manufacturing base; project reduced annual mainteance cost by 32% over legacy galvanized steel.

- Offshore Platforms: Pilot trial in Maoming subsea well head, observed no external corrosion after 1.5 years, outperforming zinc/aluminum spray coats.

- Power Plant Cooling: Guangdong Huadian Power retrofitted 5km of lines, zero blistering/flakes at 80°C continuous operation after 2 years (SGS test reference).

Professional Q&A: Plastic Coated Steel Pipe Technical Terms

- Q1: What is the standard coating thickness for Plastic coated steel pipe?

A: Standard thickness is typically 0.8–2.5mm per ISO 21809-3, customized up to 4mm for highly aggressive chemical lines. - Q2: Which material is commonly used for the plastic lining?

A: The most widely used resins include high-density Polyethylene (HDPE), epoxy powder (FBE), Polypropylene (PP), and PVC. Selection depends on fluid, temperature, and end-user requirements. - Q3: How is adhesion strength tested and why is it important?

A: Adhesion is measured (per ISO 21809-3 or ASTM D4541) by pulling the coated surface. >7 N/mm means excellent bonding, vital for long-term integrity and anti-peeling in harsh cycles. - Q4: What installation standards are applicable?

A: Most international projects adopt EN 10224/ISO 4427/ANSI B31.1 for pressure pipelines, with hot-melt or mechanical fusion required for high-integrity joints. - Q5: How do Plastic coated steel pipe compare to stainless steel or galvanized solutions?

A: While stainless steel offers premium chemical resistance and longevity, costs are x2–3 higher than plastic-coated; galvanized pipes are less resistant to acids/alkalis and have a much shorter lifespan in high humidity/corrosive settings. - Q6: Can the pipes be used for drinking (potable) water?

A: Yes, FDA and NSF-certified products are available; coatings must be food-grade (epoxy or special PE), with full traceable QA documentation supplied to municipal contracts. - Q7: What about performance in extreme temperatures?

A: Most plastic-coated pipes operate safely from -35°C up to +85°C. For higher temperatures (<110°C), special high-temp PE or FBE is applied (contact the supplier for special spec sheets).

Need more technical support? Contact our professional engineering support at Plastic coated steel pipe service page.

FAQ, Delivery & Customer Support

- What is your typical delivery cycle? Standard spec <DN600: 7 days; large/custom: 15–30 days depending on order size/coating.

- What warranty do you offer? 8–12 years for corrosion & structure; full replacement for certified manufacturer’s defects.

- Can you provide complete test/traceability reports? Yes, each batch includes mill certs, third-party testing, and traceable batch info.

- Which international standards do you comply? ISO 9001, ISO 21809, ANSI/ASTM, and FDA/NSF for potable water.

- Do you offer on-site support? Yes—engineering assistance for installation & after-sales inspection worldwide.

- How can I get a price or project evaluation? Submit your spec/drawings on our inquiry page for a fast, expert quote.

- Frost & Sullivan. "Global Plastic Pipes and Fittings Industry Analysis (2023-2028)". Link

- ISO 21809-3:2016 - "Petroleum and natural gas industries — External coatings for buried steel pipe". ISO Website

- ASTM B117/ISO 9227 Corrosion Test reference in Materials & Design Journal

- Industry insights & standards discussion at Eng-Tips Pipe Forum

- Yulong Steel Fittings Co. certification updates & process video at Official Site

Latest news

-

ANSI 150P SS304 SO FLANGE

NewsFeb.14,2025

-

ASTM A333GR6 STEEL PIPE

NewsJan.20,2025

-

ANSI B16.5 WELDING NECK FLANGE

NewsJan.15,2026

-

ANSI B16.5 SLIP-ON FLANGE

NewsApr.19,2024

-

SABS 1123 FLANGE

NewsJan.15,2025

-

DIN86044 PLATE FLANGE

NewsApr.19,2024

-

DIN2527 BLIND FLANGE

NewsApr.12,2024

-

JIS B2311 Butt-Welding Fittings LR/SR 45°/90° /180°Seamless/Weld

NewsApr.23,2024