-

Cangzhou Yulong Steel Co., Ltd.

-

Phone:

+86 13303177267 -

Email:

admin@ylsteelfittings.com

- English

- Arabic

- Italian

- Spanish

- Portuguese

- German

- kazakh

- Persian

- Greek

- French

- Russian

- Polish

- Thai

- Indonesian

- Vietnamese

- Zulu

- Korean

- Uzbek

- Hindi

- Serbian

- Malay

- Ukrainian

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Miao

- Hungarian

- Icelandic

- igbo

- irish

- Japanese

- Javanese

- Kannada

- Khmer

- Rwandese

- Afrikaans

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Esperanto

- Estonian

- Finnish

- Frisian

- Galician

- Georgian

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Dutch

- Punjabi

- Romanian

- Samoan

- Scottish Gaelic

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Turkish

- Turkmen

- Urdu

- Uighur

- Welsh

- Bantu

- Yiddish

- Yoruba

Jul . 25, 2024 09:55 Back to list

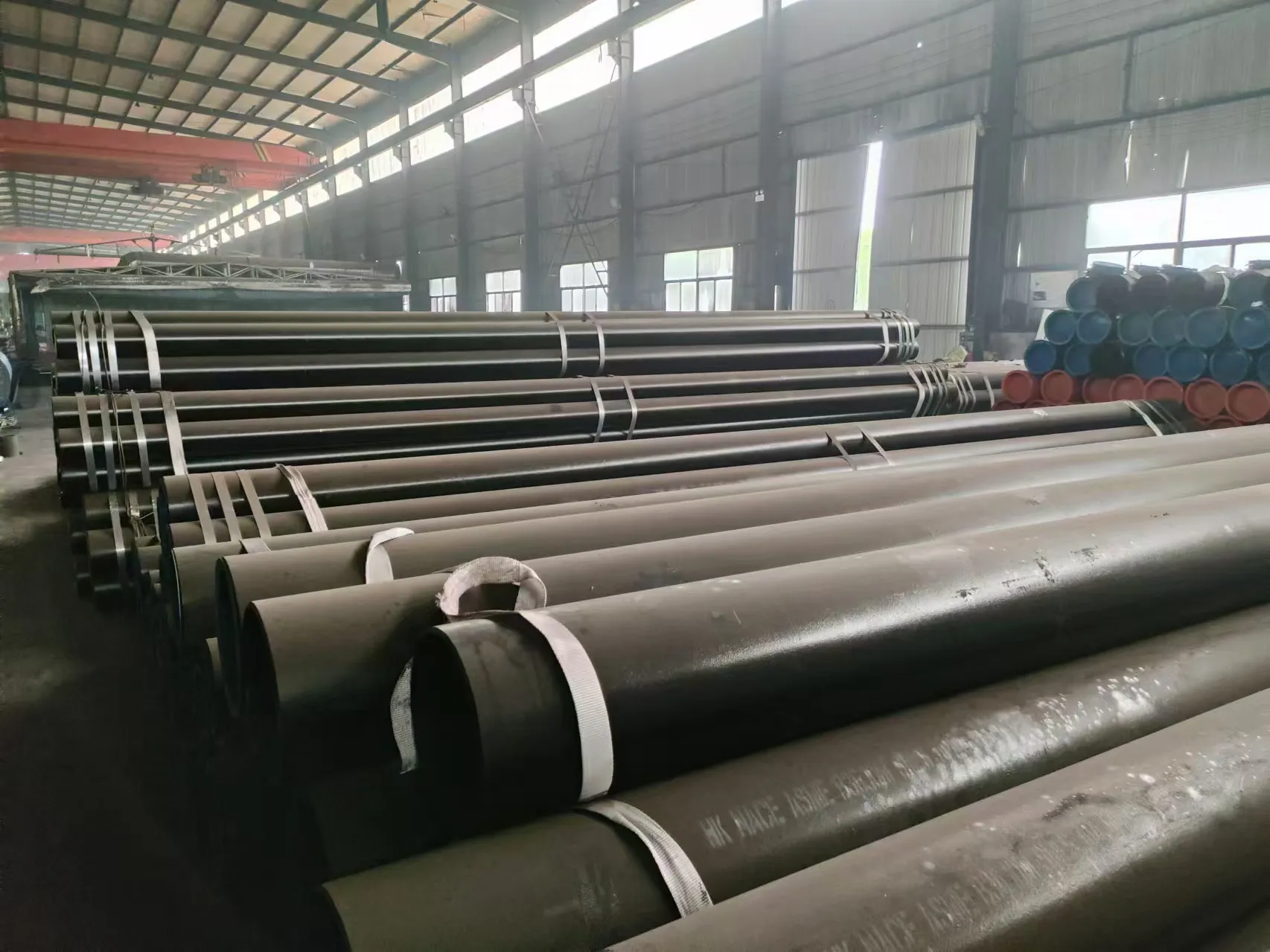

Types and Practical Uses of Seamless Steel Pipes

Seamless pipe is a long strip of steel with a hollow section and no seams around it. It is made of steel ingots or solid tube blanks through perforation and then hot-rolled, cold-rolled or cold-drawn.The main feature of seamless precision steel pipe is that it has no welding seams and can withstand greater pressure.

Features:

1. Smaller outer diameter.

2. It has high precision and can be used for small batch production.

3. The cold-drawn finished product has high precision and good surface quality.

4. The cross-sectional area of the steel pipe is more complex.

5. The performance of steel pipe is superior and the metal is denser.

Precision steel pipe calculation formula: [(outer diameter-wall thickness)*wall thickness]*0.02466 = kg/meter (weight per meter)

Types of Seamless Steel Pipes

According to different materials and uses, seamless steel pipes can be subdivided into more professional categories to meet refined production requirements.

1. Seamless steel pipes can be divided into hot-rolled pipes, cold-rolled pipes, cold-drawn pipes, extruded pipes, etc. according to different production methods.

2. According to their shape, they are divided into round tubes and special-shaped tubes. In addition to square tubes and rectangular tubes, special-shaped tubes also include round tubes, semi-circular tubes, triangular tubes, hexagonal tubes, convex-shaped tubes, plum-shaped tubes, etc.

3. According to different materials, they are divided into ordinary carbon structural pipes, low alloy structural pipes, high-quality carbon structural pipes, alloy structural pipes, stainless steel pipes, etc.

4. According to special purposes, there are boiler pipes, geological pipes, oil pipes, etc.

Seamless Steel Pipe Uses

Under more professional classifications, seamless tube pipe can be used in more professional industry construction.

1. Seamless carbon steel pipes are widely used. General-purpose seamless pipes are made of ordinary carbon structural steel, low-alloy structural steel or alloy structural steel. Structural steel rolling has the largest output and is mainly used as pipes or structural parts for conveying fluids.

2. Supplied in three categories according to different uses: a. Supplied according to chemical composition and mechanical properties; b. Supplied according to mechanical properties; c. supplied according to hydraulic pressure test. If the steel pipes supplied according to categories a and b are used to withstand liquid pressure, they must also undergo a hydraulic test. C. 3.3. Seamless pipes for special purposes include seamless pipes for boilers, seamless pipes for geology and seamless pipes for petroleum. And many more.

Treatment Methods Before Using Seamless Steel Pipes

When using seamless steel pipes, the steel pipe itself can be properly treated first for better use and transformation.

1. Cutting processing

Seamless steel pipes can be cut when in use. The purpose of cutting is to meet usage requirements. Therefore, the length and other dimensions must be measured before cutting to meet the usage requirements. When cutting, you must choose appropriate tools. Generally, metal saws, toothless saws and other tools can be used for cutting. At the same time, both ends of the fracture must be protected; that is, use fireproof and heat-resistant baffles to prevent splashing sparks. , hot iron beans, etc.

2. Polishing treatment

Seamless steel pipes need to be polished after cutting. This can be done with an angle grinder. The purpose of polishing is to avoid pipe damage caused by melting or burning of the plastic layer during the welding operation.

3. Plastic coating treatment

After the seamless steel pipe is polished, it needs to be protected by plastic coating. That is, heating the pipe mouth with oxygen and C2H2 will cause partial melting. Then apply plastic powder. It must be applied in place and ensure it is even. If it is a flange If it is a plate, it needs to be applied to the position above the water stop line. When heating, the temperature must be controlled to avoid bubbles caused by too high a temperature and the plastic layer falling off caused by the inability to melt the plastic powder at too low a temperature.

Choose the Professional Seamless Pipe Manufacturer

There are many types of welded steel pipes with a wide range of uses. It is crucial to choose a suitable steel pipe manufacturer when purchasing.Cangzhou Yulong Steel Co., Ltd. has been focusing on steel pipe production for long time, We have many years of industry experience and excellent production technology.If you have purchasing needs, please feel free to contact us.we will be fun to offer you our high-quality productions.

Latest news

-

ANSI 150P SS304 SO FLANGE

NewsFeb.14,2025

-

ASTM A333GR6 STEEL PIPE

NewsJan.20,2025

-

ANSI B16.5 WELDING NECK FLANGE

NewsJan.15,2026

-

ANSI B16.5 SLIP-ON FLANGE

NewsApr.19,2024

-

SABS 1123 FLANGE

NewsJan.15,2025

-

DIN86044 PLATE FLANGE

NewsApr.19,2024

-

DIN2527 BLIND FLANGE

NewsApr.12,2024

-

JIS B2311 Butt-Welding Fittings LR/SR 45°/90° /180°Seamless/Weld

NewsApr.23,2024