-

Cangzhou Yulong Steel Co., Ltd.

-

Phone:

+86 13303177267 -

Email:

admin@ylsteelfittings.com

- English

- Arabic

- Italian

- Spanish

- Portuguese

- German

- kazakh

- Persian

- Greek

- French

- Russian

- Polish

- Thai

- Indonesian

- Vietnamese

- Zulu

- Korean

- Uzbek

- Hindi

- Serbian

- Malay

- Ukrainian

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Miao

- Hungarian

- Icelandic

- igbo

- irish

- Japanese

- Javanese

- Kannada

- Khmer

- Rwandese

- Afrikaans

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Esperanto

- Estonian

- Finnish

- Frisian

- Galician

- Georgian

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Dutch

- Punjabi

- Romanian

- Samoan

- Scottish Gaelic

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Turkish

- Turkmen

- Urdu

- Uighur

- Welsh

- Bantu

- Yiddish

- Yoruba

Nov . 18, 2024 16:47 Back to list

Understanding the Classes of AWWA C207 Flanges: Focus on Class D

When it comes to waterworks and piping systems, adherence to industry standards is crucial for ensuring reliability, efficiency, and safety. The American Water Works Association (AWWA) plays a significant role in this by providing standards for various components of water distribution systems. One such important standard is AWWA C207, which specifies the requirements for flanges used in municipal and industrial applications. In this blog post, we will explore the classes of AWWA C207, with a particular emphasis on AWWA C207 Class D flanges.

AWWA C207: An Overview

AWWA C207 outlines the specifications for welding neck flanges that are crucial for the connection of pipe use, pipe fittings, and valves in waterworks applications. The different flange types help create a secure and leak-proof connection while providing a reliable solution that can withstand both internal and external pressures. Understanding the various classes defined in AWWA C207 is essential for engineers and project managers as they choose the appropriate flanges for their specific applications.

Classes of AWWA C207 Flanges

AWWA C207 classifies its flanges into several categories—each designed for different operating pressures and pipe sizes. The classes are as follows:

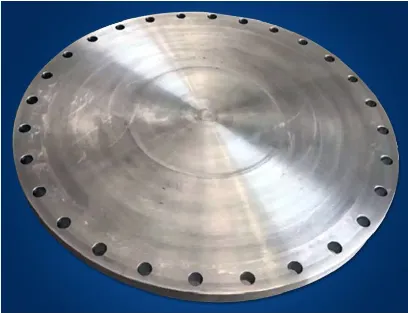

Class D Flange

One of the prominent classes within the AWWA C207 standard is the Class D flange. This flange type is designed for low-pressure applications ranging from 0 to 150 psi. Its versatility makes it widely used in water pipelines as it accommodates various sizes and materials. Class D flanges provide critical performance characteristics such as durability, ease of installation, and resistance to corrosion, making them ideal for many municipal water applications.

Other Classes

In addition to Class D, AWWA C207 defines several other classes:

- Class E Flange: Suitable for higher pressure applications, up to 300 psi.

- Class F Flange: Primarily used for very high-pressure situations exceeding 300 psi.

Each class is engineered to meet specific performance criteria, ensuring that the right flange is utilized for the desired application.

Choosing the Right AWWA Flange

When selecting AWWA flanges for your project, it is essential to consider the following factors:

1. Pressure Ratings: Ensure that the flange class aligns with the pressure requirements of your system.

2. Pipe Size: Match the flange size to the corresponding pipe diameter for proper installation.

3. Material Compatibility: Verify that the flange material is suitable for the medium being transported to prevent chemical reactions and degradation.

AWWA C207 flanges are indispensable components in water distribution and piping systems. Understanding the classification, especially the AWWA C207 Class D flange, helps engineers and project managers ensure the integrity and performance of their systems. By adhering to industry standards and selecting the appropriate flange classes, organizations can enhance their operational efficiency and maintain public safety.

For any waterworks project, make informed decisions by choosing the right AWWA flanges that meet your specific needs and requirements. By doing so, you are not only ensuring compliance with industry standards but also contributing to the overall effectiveness of water distribution networks.

Latest news

-

ANSI 150P SS304 SO FLANGE

NewsFeb.14,2025

-

ASTM A333GR6 STEEL PIPE

NewsJan.20,2025

-

ANSI B16.5 WELDING NECK FLANGE

NewsJan.15,2026

-

ANSI B16.5 SLIP-ON FLANGE

NewsApr.19,2024

-

SABS 1123 FLANGE

NewsJan.15,2025

-

DIN86044 PLATE FLANGE

NewsApr.19,2024

-

DIN2527 BLIND FLANGE

NewsApr.12,2024

-

JIS B2311 Butt-Welding Fittings LR/SR 45°/90° /180°Seamless/Weld

NewsApr.23,2024