-

Cangzhou Yulong Steel Co., Ltd.

-

Phone:

+86 13303177267 -

Email:

admin@ylsteelfittings.com

- English

- Arabic

- Italian

- Spanish

- Portuguese

- German

- kazakh

- Persian

- Greek

- French

- Russian

- Polish

- Thai

- Indonesian

- Vietnamese

- Zulu

- Korean

- Uzbek

- Hindi

- Serbian

- Malay

- Ukrainian

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Miao

- Hungarian

- Icelandic

- igbo

- irish

- Japanese

- Javanese

- Kannada

- Khmer

- Rwandese

- Afrikaans

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Esperanto

- Estonian

- Finnish

- Frisian

- Galician

- Georgian

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Dutch

- Punjabi

- Romanian

- Samoan

- Scottish Gaelic

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Turkish

- Turkmen

- Urdu

- Uighur

- Welsh

- Bantu

- Yiddish

- Yoruba

Feb . 13, 2025 13:21 Back to list

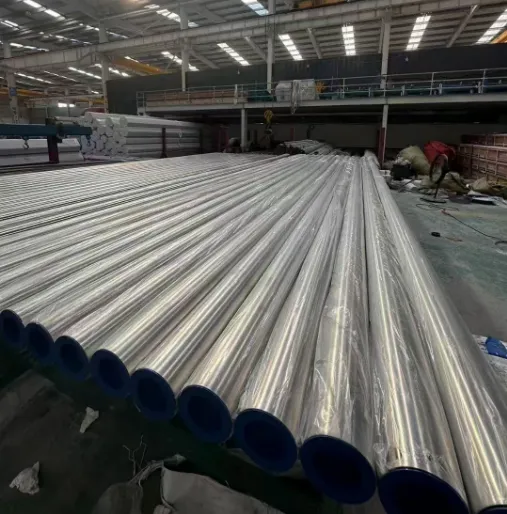

2 inch galvanized pipe for sale

2.5-inch galvanized pipes are a product category that stands out in the plumbing and construction industry due to their durability and versatility. With a history of proven performance, these pipes are favored by professionals who value long-term reliability and resistance to environmental factors. This comprehensive exploration delves into the unique attributes, applications, and maintenance tips associated with 2.5-inch galvanized pipes.

From an authoritative standpoint, numerous regulations and standards exist to govern the quality and usage of galvanized pipes. Organizations like ASTM International provide clear guidelines that ensure these pipes meet rigorous quality and safety standards. Adherence to these standards during manufacturing and installation processes is indispensable for maintaining the integrity and reliability of the pipes, preventing failures that could lead to costly repairs or safety hazards. Trustworthiness is reinforced through proper maintenance and care of 2.5-inch galvanized pipes. Regular inspections and maintenance are key to prolonging the life of the pipes. During inspections, one should look for signs of wear and tear, such as visible rust or weak spots. Although the zinc layer provides substantial protection, occasional touch-ups might be needed, especially in areas where the coating is compromised. In cases of extensive damage or deterioration, it may be necessary to replace the affected sections to prevent further issues. In addition to these practical insights, considering the environmental impact of galvanized pipes is important. Their longevity and recyclability contribute to sustainable construction practices. Once they reach the end of their usable life, these pipes can be recycled, thus minimizing waste and conserving natural resources. This eco-friendly aspect makes them a preferred choice among environmentally conscious builders and architects. To summarize, the 2.5-inch galvanized pipe is a multifunctional component in construction, synonymous with strength and resistance. Ensuring effective application involves understanding the technical specifications, adhering to industry standards, and conducting regular maintenance. When these factors are combined, the result is a durable and reliable piping solution that stands the test of time. For professionals seeking to enhance the quality and durability of their projects, 2.5-inch galvanized pipes offer a dependable option grounded in both historical performance and modern engineering advancements.

From an authoritative standpoint, numerous regulations and standards exist to govern the quality and usage of galvanized pipes. Organizations like ASTM International provide clear guidelines that ensure these pipes meet rigorous quality and safety standards. Adherence to these standards during manufacturing and installation processes is indispensable for maintaining the integrity and reliability of the pipes, preventing failures that could lead to costly repairs or safety hazards. Trustworthiness is reinforced through proper maintenance and care of 2.5-inch galvanized pipes. Regular inspections and maintenance are key to prolonging the life of the pipes. During inspections, one should look for signs of wear and tear, such as visible rust or weak spots. Although the zinc layer provides substantial protection, occasional touch-ups might be needed, especially in areas where the coating is compromised. In cases of extensive damage or deterioration, it may be necessary to replace the affected sections to prevent further issues. In addition to these practical insights, considering the environmental impact of galvanized pipes is important. Their longevity and recyclability contribute to sustainable construction practices. Once they reach the end of their usable life, these pipes can be recycled, thus minimizing waste and conserving natural resources. This eco-friendly aspect makes them a preferred choice among environmentally conscious builders and architects. To summarize, the 2.5-inch galvanized pipe is a multifunctional component in construction, synonymous with strength and resistance. Ensuring effective application involves understanding the technical specifications, adhering to industry standards, and conducting regular maintenance. When these factors are combined, the result is a durable and reliable piping solution that stands the test of time. For professionals seeking to enhance the quality and durability of their projects, 2.5-inch galvanized pipes offer a dependable option grounded in both historical performance and modern engineering advancements.

Latest news

-

ANSI 150P SS304 SO FLANGE

NewsFeb.14,2025

-

ASTM A333GR6 STEEL PIPE

NewsJan.20,2025

-

ANSI B16.5 WELDING NECK FLANGE

NewsJan.15,2026

-

ANSI B16.5 SLIP-ON FLANGE

NewsApr.19,2024

-

SABS 1123 FLANGE

NewsJan.15,2025

-

DIN86044 PLATE FLANGE

NewsApr.19,2024

-

DIN2527 BLIND FLANGE

NewsApr.12,2024

-

JIS B2311 Butt-Welding Fittings LR/SR 45°/90° /180°Seamless/Weld

NewsApr.23,2024