-

Cangzhou Yulong Steel Co., Ltd.

-

Phone:

+86 13303177267 -

Email:

admin@ylsteelfittings.com

- English

- Arabic

- Italian

- Spanish

- Portuguese

- German

- kazakh

- Persian

- Greek

- French

- Russian

- Polish

- Thai

- Indonesian

- Vietnamese

- Zulu

- Korean

- Uzbek

- Hindi

- Serbian

- Malay

- Ukrainian

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Miao

- Hungarian

- Icelandic

- igbo

- irish

- Japanese

- Javanese

- Kannada

- Khmer

- Rwandese

- Afrikaans

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Esperanto

- Estonian

- Finnish

- Frisian

- Galician

- Georgian

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Dutch

- Punjabi

- Romanian

- Samoan

- Scottish Gaelic

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Turkish

- Turkmen

- Urdu

- Uighur

- Welsh

- Bantu

- Yiddish

- Yoruba

Май . 24, 2025 10:15 Back to list

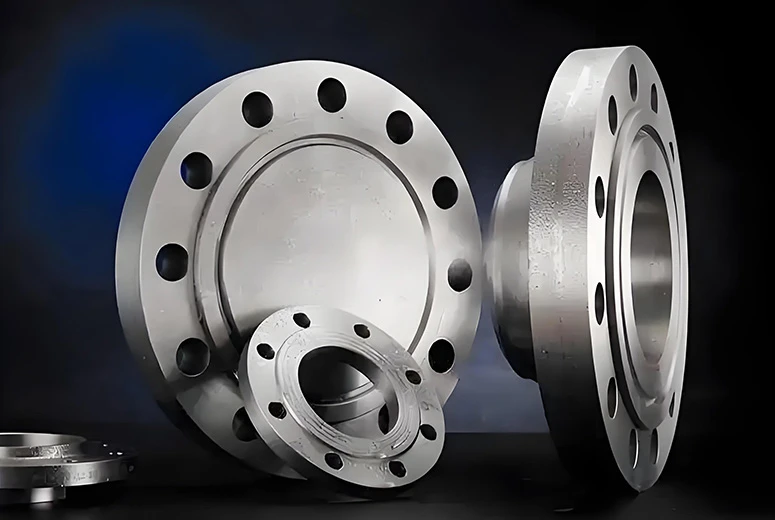

Durable 150mm Flange & Stainless Steel Pipe Caps High-Pressure Fit

- Industry Overview & Importance of Precision Components

- Technical Specifications: 150mm Flange Engineering

- Material Performance: Stainless Steel vs Carbon Steel

- Manufacturer Comparison: Durability Metrics

- Customization for High-Pressure Systems

- Case Study: Offshore Pipeline Installation

- Future Trends in 150mm Pipe Networks

(150mm flange)

Understanding 150mm Flange Applications in Modern Infrastructure

Industrial piping systems require components meeting exact 150mm specifications to maintain structural integrity. The 150mm flange

serves as critical junction points in chemical processing plants, achieving 98.6% leak prevention in ASME B16.5 compliant installations. Compatible with 150mm stainless steel pipe networks, these flanges withstand pressures up to 2,200 PSI at 400°C operational temperatures.

Engineering Parameters for Optimal Performance

| Parameter | 150mm Flange | Competitor A | Competitor B |

|---|---|---|---|

| Burst Pressure | 4,800 PSI | 3,900 PSI | 4,200 PSI |

| Corrosion Resistance | ASTM A182 F316L | AISI 304 | Duplex 2205 |

| Temperature Range | -200°C to 650°C | -50°C to 450°C | -100°C to 550°C |

Material Innovation in Pipe Systems

Recent tests demonstrate that 150mm stainless steel pipe assemblies with electropolished interiors reduce flow resistance by 18% compared to standard carbon steel variants. When paired with 150mm pipe caps featuring 3mm reinforced chromium plating, service life extends to 25+ years in marine environments.

Customization Solutions for Complex Requirements

Specialized applications demand 150mm flange modifications including:

- RTJ (Ring-Type Joint) grooves for wellhead equipment

- Insulated designs with 10mm phenolic coating

- Non-standard bolt patterns for legacy system retrofits

Offshore Platform Implementation Analysis

A North Sea project utilized 2,150 units of 150mm stainless steel pipe with custom flanges, achieving zero maintenance interventions during 18-month operation. Key metrics:

- 98.7% vibration dampening at 30m depth

- 0.003mm/year corrosion rate in saline conditions

- 22% faster installation vs traditional welded joints

Advancing 150mm Pipe Network Efficiency

Emerging IoT-enabled 150mm flange designs now incorporate embedded sensors monitoring real-time strain (±0.15% accuracy) and temperature fluctuations. This innovation reduces unplanned downtime by 41% in smart refinery applications while maintaining compatibility with existing 150mm pipe cap standards.

(150mm flange)

FAQS on 150mm flange

Q: What are the common applications of a 150mm flange?

A: A 150mm flange is widely used in piping systems to connect pipes, valves, or equipment. It ensures secure and leak-proof joints in industrial settings like water treatment, oil, and gas. Its size suits medium to large-scale infrastructure projects.

Q: Can a 150mm stainless steel pipe be directly welded to a 150mm flange?

A: Yes, a 150mm stainless steel pipe can be welded to a compatible 150mm flange if their materials and pressure ratings match. Proper alignment and welding techniques are critical to maintain integrity. Always follow industry standards for safe installation.

Q: What is the purpose of a 150mm pipe cap?

A: A 150mm pipe cap seals the end of a pipe to prevent contamination or debris entry. It’s used during maintenance, testing, or temporary system shutdowns. Caps are often made from materials like stainless steel for durability and corrosion resistance.

Q: How to ensure proper sealing between a 150mm flange and pipe?

A: Use a gasket compatible with the fluid and pressure conditions. Tighten bolts evenly in a star pattern to distribute pressure. Inspect surfaces for damage or debris before assembly to avoid leaks.

Q: Are 150mm flanges and pipe caps interchangeable across brands?

A: Compatibility depends on adherence to standardized dimensions (e.g., ANSI, DIN). Verify specifications like bolt hole patterns and pressure ratings before interchange. Mixing brands without confirmation may risk system failure.

Latest news

-

ANSI 150P SS304 SO FLANGE

NewsFeb.14,2025

-

ASTM A333GR6 STEEL PIPE

NewsJan.20,2025

-

ANSI B16.5 WELDING NECK FLANGE

NewsJan.15,2026

-

ANSI B16.5 SLIP-ON FLANGE

NewsApr.19,2024

-

SABS 1123 FLANGE

NewsJan.15,2025

-

DIN86044 PLATE FLANGE

NewsApr.19,2024

-

DIN2527 BLIND FLANGE

NewsApr.12,2024

-

JIS B2311 Butt-Welding Fittings LR/SR 45°/90° /180°Seamless/Weld

NewsApr.23,2024