Properties of Carbon Steel Pipes

- 1.Material Composition: Carbon steel is primarily made from iron and carbon. The amount of carbon affects the hardness and tensile strength of the steel.

- 2. Strength and Durability: Carbon steel pipes offer high tensile strength, making them suitable for high-pressure fire protection systems.

- 3. Heat Resistance: Carbon steel can withstand high temperatures, which is critical in fire conditions.

- 4. Corrosion Resistance: While carbon steel is vulnerable to corrosion, appropriate coatings (such as galvanization) can enhance its resistance to rust and corrosion, extending its lifespan.

- 5. Weldability: Carbon steel is easily weldable, facilitating the installation of complex pipe systems.

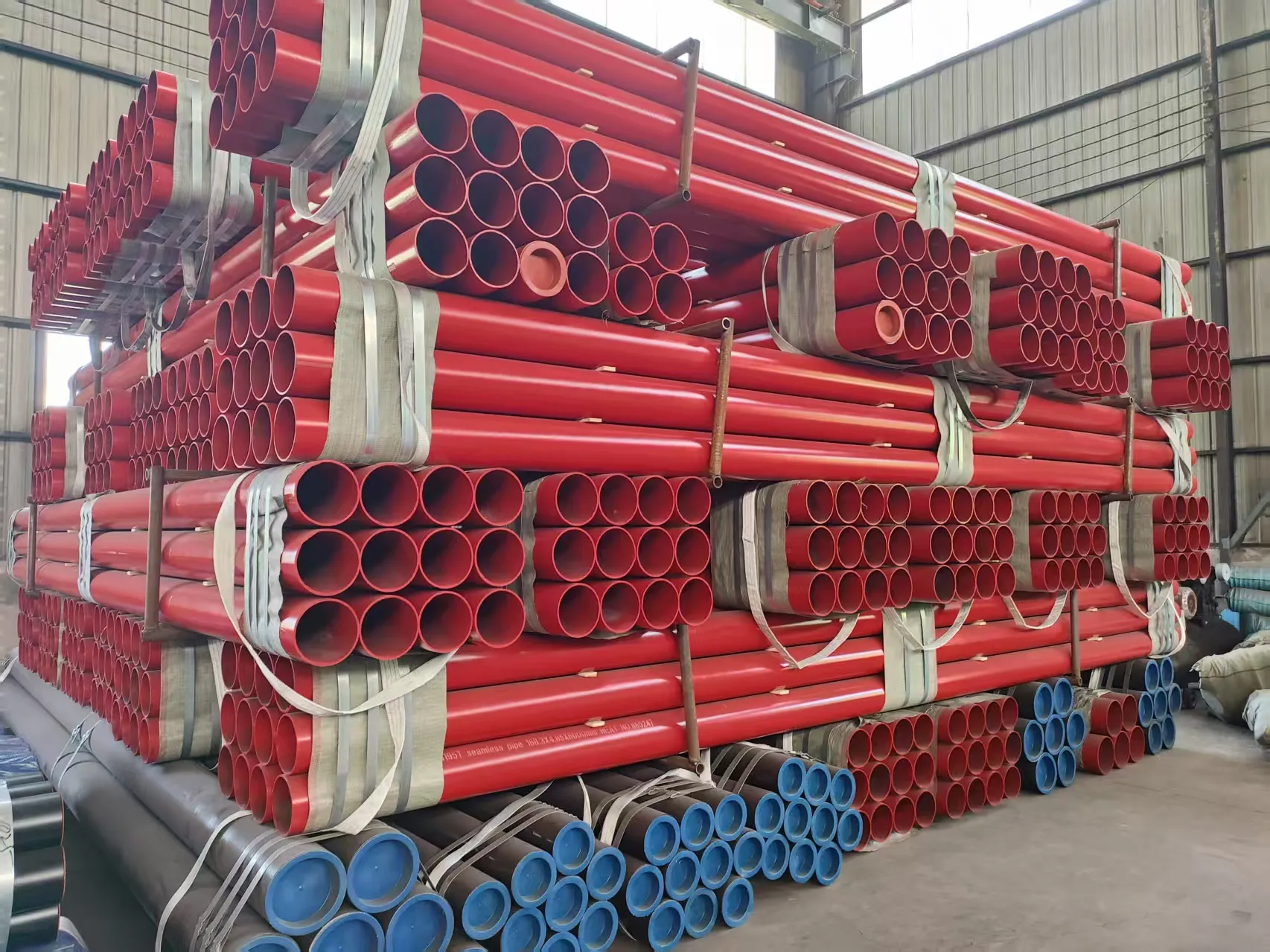

- Applications of Fire Carbon Steel Pipes

- 1. Fire Sprinkler Systems: Frequently used in wet, dry, and pre-action sprinkler systems in commercial buildings, warehouses, and industrial facilities.

- 2. Standpipe Systems: Used in tall buildings for firefighters to access water supply at various floors.

- 3. Hydrant Systems: Installed as part of fire hydrant systems to ensure a reliable water supply for firefighting efforts.

- 4. Fire Main Systems: Integral to fire main piping that connects to the municipal water supply or storage tanks.

- Advantages of Fire Carbon Steel Pipes

- 1. Cost-Effective: Carbon steel pipes are generally more affordable compared to other materials, such as stainless steel or copper.

- 2. High Tensile Strength: They are capable of handling high pressures and resist impact, making them suitable for various fire protection applications.

- 3. Availability: Carbon steel pipes are readily available in various sizes, making them convenient for large-scale projects.

- 4. Long Lifespan: With proper installation and maintenance, carbon steel pipes can have a long service life.

- 5. Versatility: Suitable for various fire protection systems, they can be used in both commercial and industrial applications.

- Considerations for Usage

- 1. Corrosion Management: Regular inspections and maintenance are crucial to prevent corrosion. Coatings or linings should be used as necessary, especially in humid environments.

- 2. Installation Standards: Compliance with relevant local, national, and international fire safety codes and standards (such as NFPA standards in the U.S.) is essential for the effective use of carbon steel pipes in fire protection systems.

- 3. Thermal Expansion: Carbon steel pipes can expand and contract with temperature changes. Proper consideration for these changes during installation is critical to avoid stress points and potential failures.

- 4. Welding and Joining Techniques: Proper welding techniques and joint designs are crucial to integrity and performance in fire protection systems.

- Fa'ai'uga Fire carbon steel pipes are a vital element in fire protection systems, providing a reliable and effective means of delivering water for fire suppression. Their strength, affordability, and versatility make them a preferred choice in many applications. However, attention should be given to maintenance and installation practices to ensure their performance and longevity in emergency situations. If you have any specific questions or need more detailed information, feel free to ask!

Tusi lau savali iinei ma lafo mai ia i matou