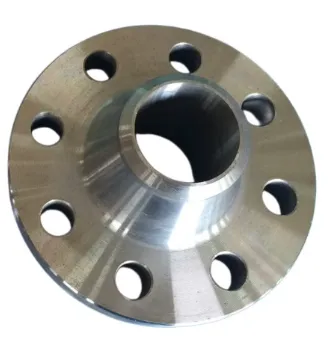

P245GH WN Flange refers to the butt welding flange made of P245GH. The following is a detailed introduction:

Meafaitino

Chemical composition: P245GH is a European standard pressure vessel steel with strict chemical composition. The carbon content is generally controlled at a low level, not exceeding 0.20%, to ensure the toughness and weldability of the material. The manganese content is 0.50% - 1.30%, which helps to improve the strength of the steel. At the same time, it contains a small amount of silicon, phosphorus, sulfur and other elements, among which the phosphorus and sulfur content are usually limited to a low level, generally not exceeding 0.025%, to ensure the quality and performance of the steel.

Mea fa'ainisinia: It has good comprehensive mechanical properties, the yield strength is not less than 245MPa, and the tensile strength is between 415 - 550MPa. Its elongation after fracture is not less than 22%, which enables the material to have a certain deformation ability and is not easy to break when subjected to pressure and external force. It has good impact resistance and fatigue resistance, and can adapt to the use requirements under different working conditions.

Processing performance: The material has good processability and excellent weldability. It can be firmly connected to pipelines or other equipment through welding process, and the welded joint has high strength and reliability. At the same time, it also has good cold and hot processing performance, and is easy to perform forging, rolling, bending and other processing operations, which can meet the manufacturing needs of butt welding flanges of different shapes and sizes.

Vaega fa'avae

Butt welding connection: WN is butt welding (Welding Neck). When this flange is connected to the pipeline, butt welding is adopted. The neck of the flange matches the outer diameter of the pipeline and has a certain taper. When welding, the flange neck is butt welded to the pipeline to form an integral connection structure. This connection method can provide higher strength and sealing, reduce the possibility of leakage, and is suitable for high pressure, high temperature, flammable and explosive working conditions with high sealing requirements.

Fa'amaufa'ailoga luga: Common sealing surface forms include raised surface (RF), concave and convex surface (MFM), tongue and groove surface (TG), etc. Raised face sealing surface is widely used. There is a raised ring on the sealing surface of the flange. By cooperating with the gasket, it can achieve a better sealing effect; the concave and convex surface and the tongue and groove surface sealing surface have better sealing performance and are suitable for occasions with higher pressure and more stringent sealing requirements. The concave surface and the convex surface, the tongue and the groove surface cooperate with each other, which can effectively prevent the gasket from being squeezed out and improve the reliability of the seal.

Talosaga fanua

Alamanuia Petrochemical: In the process of petroleum refining and chemical production, P245GH WN Flange is widely used in various high-temperature, high-pressure and corrosive medium pipeline systems. For example, on the connecting pipes of equipment such as petroleum cracking units, synthetic ammonia units, and large chemical reactors, butt welding flanges can ensure the safe operation of the pipeline system under harsh working conditions and prevent medium leakage.

Alamanuia malosi: In the fields of power production such as thermal power generation and nuclear power generation, P245GH WN Flange is often used in important pipeline systems such as steam pipes and main water supply pipes. These pipelines are subjected to high temperature and high pressure during operation. The high strength and good sealing performance of the butt-welded flange can ensure the reliability of the pipeline system and guarantee the stable operation of power production.

Alamanuia kasa faalenatura: P245GH WN Flange also has important applications in the extraction, transportation and processing of natural gas. For example, in pump stations and metering stations of long-distance natural gas pipelines, butt-welded flanges are used to connect pipelines and equipment. They can withstand the high pressure during natural gas transportation, ensure the sealing of the pipeline system, and prevent natural gas leakage.