Key Characteristics:

- 1.Material Composition:

- - API 5L X65 pipes are primarily made from carbon steel, often with small additions of alloying elements to improve specific properties.

- - Typical chemical composition may include:

- - Carbon (C): ≤ 0.26%

- - Manganese (Mn): 1.20% - 1.60%

- - Phosphorus (P): ≤ 0.025%

- - Sulfur (S): ≤ 0.025%

- - Silicon (Si): ≤ 0.40%

- 2. Mechanical Properties:

- - Yield Strength: Minimum yield strength of 65,000 psi (448 MPa).

- - Tensile Strength: Typically ranges from 80,000 psi to 100,000 psi (552 MPa to 690 MPa).

- - Elongation:Generally around 18% to 22%, depending on the thickness of the pipe.

- 3. Dimensions and Specifications:

- - API 5L X65 pipes are available in various sizes and wall thicknesses.

- - Nominal Pipe Sizes (NPS) usually range from ½ inch to 48 inches or larger.

- - The wall thickness can align with different schedules, such as Schedule 40 and Schedule 80, based on application requirements.

- 4. Manufacturing Process:

- - Pipes can be manufactured using two primary methods:

- - Seamless: These pipes are formed without seams, enhancing structural integrity and strength.

- - Welded: Comprised of rolled flat steel plates or coils that are welded together longitudinally.

- - The manufacturing process adheres to stringent quality standards, typically involving non-destructive testing (NDT) to identify any defects.

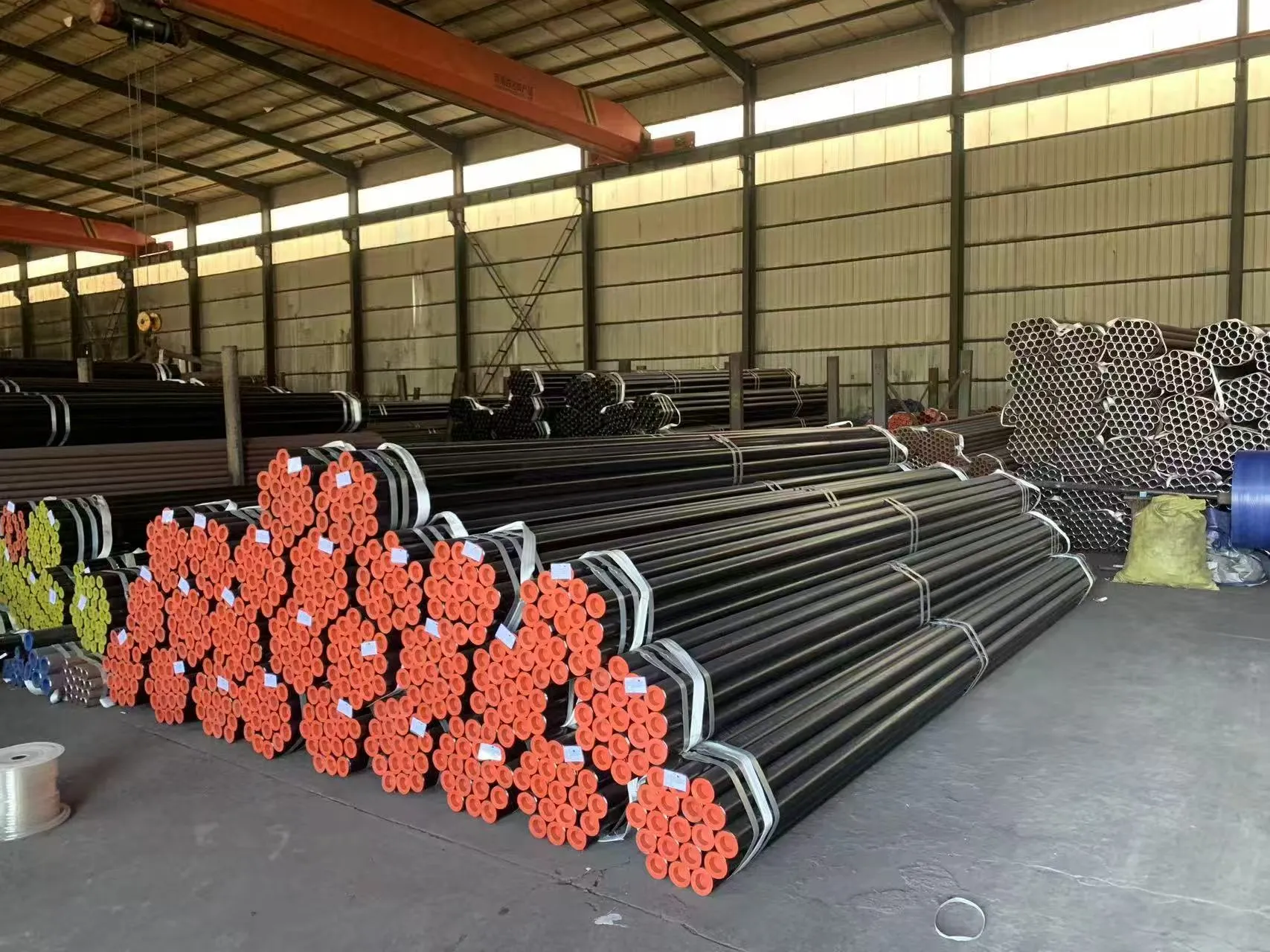

- 5. Coatings and Finishes:

- - To enhance resistance to corrosion and improve durability, API 5L X65 pipes may be coated with various materials, including:

- - Bare steel (uncoated)

- - Fusion Bond Epoxy (FBE)

- - Three-Layer Polyethylene (3LPE)

- - Three-Layer Polypropylene (3LPP)

- 6. Applications:

- - API 5L X65 pipes are primarily utilized in the oil and gas industry for transporting petroleum and natural gas.

- - Suitable for high-pressure and challenging environments, such as offshore pipelines and onshore hydrocarbon transportation.

- - Also used in water distribution and various infrastructure projects.

- 7. Standards and Compliance:

- - API 5L X65 pipes conform to API standards, ensuring reliability and safety for pipeline applications.

- - Additional regulatory standards (such as ISO and ASTM) may be applicable depending on the specific project requirements.

- 8. Testing and Quality Control:

- - API 5L X65 pipes undergo rigorous testing to ensure they meet quality and performance standards, which may include:

- - Hydrostatic testing to confirm strength and detect leaks.

- - Non-destructive testing (e.g., ultrasonic or radiographic methods) to assess integrity.

- - Mechanical testing to verify yield and tensile properties.

- Summary:

- API 5L X65 pipes are designed to provide high strength and durability for the transportation of fluids in various industrial applications, particularly in the oil and gas sector. With a minimum yield strength of 65,000 psi, these carbon steel pipes are suitable for demanding pipeline conditions, including high-pressure environments. When selecting API 5L X65 pipes, consider critical factors such as diameter, wall thickness, coating options, and adherence to relevant standards to ensure optimal performance. Regular inspections and maintenance are essential for ensuring the reliability and safety of these pipeline systems over time.

உங்கள் செய்தியை இங்கே எழுதி எங்களுக்கு அனுப்பவும்