-

Cangzhou Yulong Steel Co., Ltd.

-

Phone:

+86 13303177267 -

Email:

admin@ylsteelfittings.com

- English

- Arabic

- Italian

- Spanish

- Portuguese

- German

- kazakh

- Persian

- Greek

- French

- Russian

- Polish

- Thai

- Indonesian

- Vietnamese

- Zulu

- Korean

- Uzbek

- Hindi

- Serbian

- Malay

- Ukrainian

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Miao

- Hungarian

- Icelandic

- igbo

- irish

- Japanese

- Javanese

- Kannada

- Khmer

- Rwandese

- Afrikaans

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Esperanto

- Estonian

- Finnish

- Frisian

- Galician

- Georgian

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Dutch

- Punjabi

- Romanian

- Samoan

- Scottish Gaelic

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Turkish

- Turkmen

- Urdu

- Uighur

- Welsh

- Bantu

- Yiddish

- Yoruba

அக் . 30, 2024 10:39 Back to list

blank flange plumbing

Understanding Blank Flange Plumbing A Comprehensive Overview

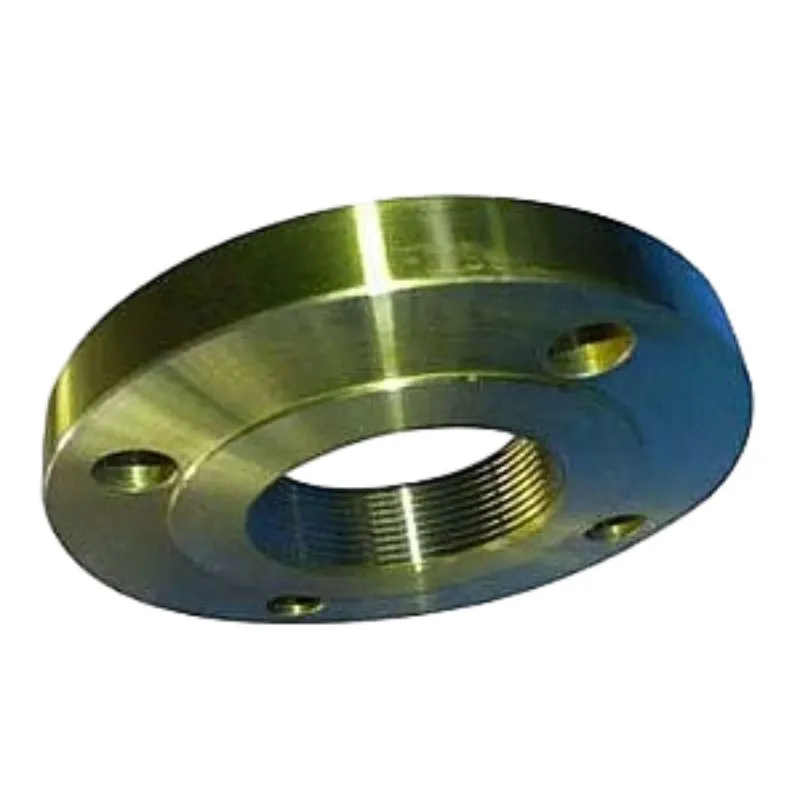

In the world of plumbing and piping systems, the use of various components is essential for the effective functioning of the entire network. Among these components, a blank flange plays a crucial role. A blank flange is essentially a type of flange that does not have any opening. It is utilized primarily to seal the end of a pipe, effectively preventing the flow of fluids or gases, thus providing a barrier. This article delves into the significance of blank flange plumbing, its applications, and best practices.

The Function of Blank Flanges

Blank flanges serve several important functions in plumbing systems. Primarily, they are used to close off the end of a pipe or a vessel. This closure is essential in scenarios where maintenance or inspections are required, allowing for safe operations without the risk of leaks or spills. Furthermore, blank flanges can help in testing the pressure within a system. By sealing off a section of piping, technicians can effectively assess whether there are any leaks or weaknesses in the system under pressure conditions.

Another significant application of blank flanges is in construction and industrial settings. They are essential for pipeline installations where future extensions may be needed. By using blank flanges, technicians can easily adapt the system to include additional piping or machinery without needing to dismantle existing structures.

Material Considerations

blank flange plumbing

Blank flanges are manufactured from various materials, including carbon steel, stainless steel, and plastic, each chosen based on the specific requirements of the plumbing system. Carbon steel flanges are known for their strength and are typically used in high-pressure applications. Stainless steel flanges, on the other hand, offer corrosion resistance and are ideal for plumbing systems that convey corrosive substances or are situated in harsh environmental conditions. Conversely, plastic flanges are often used in applications involving non-corrosive fluids, providing a lightweight and cost-effective solution.

Installation and Best Practices

Proper installation of blank flanges is essential for ensuring a leak-proof seal. It is crucial to select the appropriate size and pressure rating to match the connecting pipes. Additionally, implementing proper torque specifications during the bolting process is fundamental. Uneven torque can lead to warping and ultimately result in leaks.

Before installation, it is advisable to inspect the flanges for any surface damage or deformities. The gasket selection is equally important, as it will significantly influence the sealing capabilities. Rubber and metal gaskets are commonly used, but the choice should depend on the operational parameters of the system.

Conclusion

In conclusion, blank flanges are an integral component of plumbing systems, providing essential sealing capabilities and facilitating ease of maintenance. Understanding their applications, material choices, and best practices for installation can significantly enhance the reliability and efficiency of plumbing networks. As industries strive for optimal safety standards and operational effectiveness, blank flanges will continue to play a pivotal role in ensuring that plumbing systems operate seamlessly and without interruption. By investing in quality components and adhering to best practices, professionals can ensure that their plumbing systems remain robust and reliable for years to come.

Latest news

-

ANSI 150P SS304 SO FLANGE

NewsFeb.14,2025

-

ASTM A333GR6 STEEL PIPE

NewsJan.20,2025

-

ANSI B16.5 WELDING NECK FLANGE

NewsJan.15,2026

-

ANSI B16.5 SLIP-ON FLANGE

NewsApr.19,2024

-

SABS 1123 FLANGE

NewsJan.15,2025

-

DIN86044 PLATE FLANGE

NewsApr.19,2024

-

DIN2527 BLIND FLANGE

NewsApr.12,2024

-

JIS B2311 Butt-Welding Fittings LR/SR 45°/90° /180°Seamless/Weld

NewsApr.23,2024