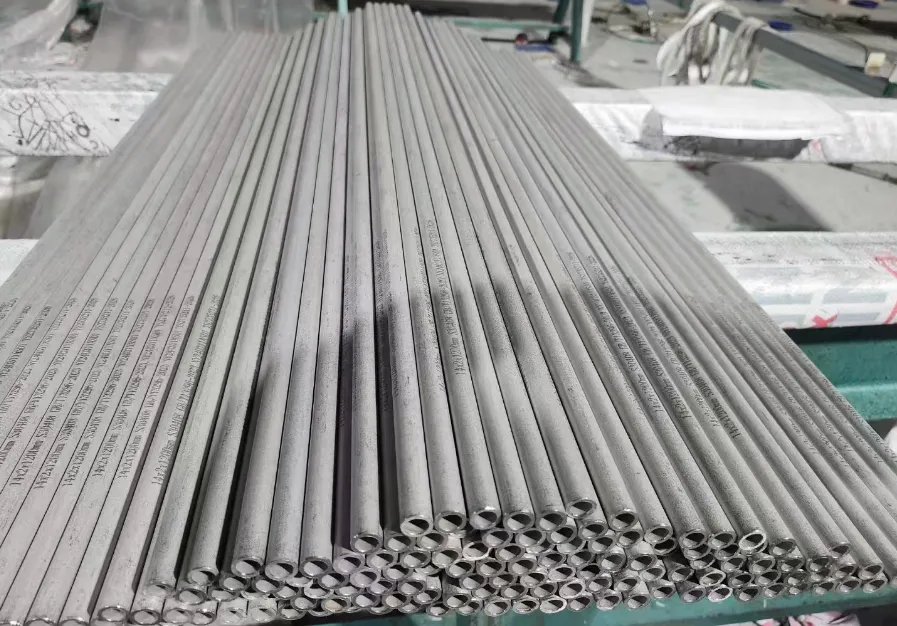

Stainless Steel Pipe (SS Pipe/Tube), Seamless Stainless Steel Pipe, Stainless Steel Seamless Pipe, Stainless Steel Welded Pipe, Stainless Steel ERW Pipe, Stainless Steel Sanitary Tube

Sizes:1/8″ thru 24″

Grade: TP 304L/H, 316L/H, 309/S, 310/S, 317/L, 321/H, 347/H, 904L, 201, 330, 254SMO, 410.

Specifications: ASTM A312, ASTM A213, ASTM A358, ASTM A813, ASTM A814

Stainless Steel Pipe (SS Pipe): Stainless steel pipe is a tubular product made of stainless steel material. Stainless steel is a special alloy steel known for its excellent corrosion resistance and is widely used in industrial and civil fields. The stainless steel material used in stainless steel pipes has strong oxidation resistance and high temperature resistance, and can be used under high temperature and high pressure conditions.

Classification of stainless steel pipes:

According to different alloying elements and proportions, stainless steel can be divided into many types, such as austenitic stainless steel, martensitic stainless steel, ferritic stainless steel, etc. Each type has its unique properties and applications.

According to the production process of steel pipes, stainless steel pipes can be divided into two basic categories: stainless steel தடையற்ற குழாய்கள் and stainless steel welded pipes (seamed steel pipes). According to the outer diameter and shape of steel pipes, they can be divided into round pipes and special-shaped pipes. The most widely used are circular steel pipes, but there are also some special-shaped steel pipes such as square, rectangular, semicircular, hexagonal, equilateral triangle, and octagonal shapes.

Stainless Steel Seamless Pipe:

Stainless steel seamless pipe is a pipe material made by seamless technology. Its internal and external surfaces have high smoothness, which greatly improves the corrosion resistance, high temperature resistance and compressive strength of the pipe. Therefore, stainless steel seamless pipes are widely used in high-end fields such as chemical industry, petroleum, and electric power, as well as general fields such as construction and automobiles.

Stainless steel seamless pipes also have some advantages during installation and use, such as simple connection methods, low installation costs, and easy maintenance. This makes stainless steel seamless pipe an ideal choice for many occasions.

Stainless Steel Welded Pipe:

Stainless steel welded pipe is a pipe material made through welding process, which has the advantages of relatively high cost-effectiveness and simple manufacturing process. Therefore, in some scenarios where appearance requirements are not high and installation conditions are limited, stainless steel welded pipes are a more economical and affordable choice.

Stainless steel welded pipes can be divided into two types: straight seam welded pipes (ERW) and spiral welded pipes (SSAW) according to the weld form. Straight seam welded pipe means that the welded joints are in a straight line, while spiral welded pipe means that the steel strip is rolled into a pipe blank at a certain spiral angle and then welded. These two classifications are mainly based on differences in production processes.

Stainless Steel ERW Pipe is a straight seam electric resistance welded pipe, abbreviated as ERW, which is a type of high-frequency straight seam electric resistance welded pipe. This kind of pipe uses the skin effect and proximity effect of high-frequency current to heat and melt the edge of the pipe blank, and then performs pressure welding under the action of the extrusion roller to achieve production.

ERW steel pipes occupy an important position in the field of transportation pipes in the world due to their high production efficiency, low cost, material saving and easy automation. It is mainly used to transport vapor and liquid objects such as oil and natural gas, and can meet various requirements of high and low pressure.

Grade of stainless steel pipe

|

Material |

ASTM Grade |

UNS Grade |

DIN Grade |

JIS Grade |

Steel Name |

|

Austenitic |

TP 304 |

S30400 |

1.4301 |

SUS304TB |

X5CrNi18-20 |

|

TP 304L |

S30403 |

1.4306 |

|

X2CrNi19-11 |

|

|

TP 304L |

S30403 |

1.4307 |

SUS304LTB |

X2CrNi18-9 |

|

|

TP 304H |

S30409 |

1.4948 |

SUS304HTB |

X6CrNi18-10 |

|

|

TP 310S |

S31008 |

1.4845 |

SUS310STB |

X8CrNi25-21 |

|

|

TP 310H |

S31009 |

|

|

|

|

|

|

|

1.4335 |

|

X1CrNi25-21 |

|

|

TP 316 |

S31600 |

1.4401 |

SUS316TB |

X5CrNiMo17-12-2 |

|

|

TP 316L |

S31603 |

1.4404 |

SUS316LTB |

X2CrNiMo17-12-2 |

|

|

TP 316H |

S31609 |

1.4918 |

SUS316HTB |

X6CrNiMo17-13-2 |

|

|

TP 316Ti |

S31635 |

1.4571 |

SUS316TiTB |

X6CrNiMo17-12-2 |

|

|

TP 321 |

S32100 |

1.4541 |

SUS321TB |

X6CrNiNb18-10 |

|

|

TP 312H |

S32109 |

1.4941 |

SUS321HTB |

X6CrNiTiB18-10 |

|

|

TP 347 |

S34700 |

1.455 |

SUS347TB |

X6CrNiNb18-10 |

|

|

TP 347H |

S34709 |

1.4912 |

SUS347HTB |

X7CrNiNb18-10 |

|

|

Ferritic & Martensitic |

TP 405 |

S41500 |

1.4002 |

SUS 405TB |

X6CrAl13 |

|

TP 410 |

S41000 |

1.4006 |

SUS 410TB |

X12Cr13 |

|

|

TP 430 |

S43000 |

1.4016 |

SUS 430TB |

X6Cr17 |

|

|

Ferritic / Austenitic |

|

UNS S31803 |

|

|

|

|

2205 |

UNS S32205 |

1.4462 |

|

X2CrNiMoN22-5-3 |

|

|

2507 |

UNS S32750 |

1.441 |

|

X2CrNiMoN25-7-4 |

|

|

|

UNS S32760 |

1.4501 |

|

X2CrNiMoCuWN25-7-4 |

Standard of stainless steel pipe

|

A 213 / SA 213 |

Seamless Ferritic and Austenitic Alloy-steel Boiler,Superheater and Heat-Exchanger Tubes |

|

A 249 / SA 249 |

Welded Austenitic Steel Boiler,Superheater, Hear Exchanger and Condenser Tubes |

|

A 268 / SA 268 |

Seamless and Welded Ferritic and Martensitic Stainless Steel Tubing for General Service |

|

A 269 |

Seamless and Welded Austenitic Stainless Steel Tubing for General Service |

|

A 312 / SA 312 |

Seamless,Welded and Heavily Cold Worked Austenitic Stainless Steel Pipes |

|

A 376 / SA 376 |

Seamless Austenitic Steel Pipe for High-temperature Service |

|

A 688 / SA 688 |

Seamless and Welded Austenitic Stainless Steel Feedwater Heater Tubes |

|

A 789 / SA 789 |

Seamless and Welded Ferritic/Austenitic Stainless Steel Tubing for General Service |

|

A 790 / SA 790 |

Seamless and Welded Ferritic/Austenitic Stainless Steel Pipe |

|

A 999 / SA 999 |

General Requirement for Alloy and Stainless Steel Pipe |

|

A 1016 / SA 1016 |

General Requirement for Ferritic Alloy Steel, Austenitic Alloy Steel and Stainless Steel Tubes |

|

European Standard |

|

|

DIN EN 10216-5 |

Seamless Steel Tubes for Pressure Purposes |

|

DIN EN 10217-7 |

Welded Steel Tubes for Pressure Purposes |

|

DIN EN 10297-2 |

Seamless Steel Tubes for Mechanical and General Engineering Purposes |

|

DIN EN 10305-1 |

Steel Tubes for Precision Application |

|

German Standard |

|

|

DIN 11850 |

Stainless Steel Tubes for the Food and Chemical Industries-Dimensions, Materials |

|

DIN 17455 |

General Purpose Welded Circular Stainless Steel Tubes |

|

DIN 17456 |

General Purpose Seamless Circular Stainless Steel Tubes |

|

DIN 17457 |

Welded Circular Austenitic Stainless Steel Tubes Subject to Special Requirement |

|

DIN 17458 |

Seamless Circular Austenitic Stainless Steel Tubes Subject to Special Requirement |

|

DIN 28180 |

Seamless Steel Tubes for Heat-exchanger |

|

DIN 11850 |

Welded Tubes and Pipe for Food, Beverages,Chemical&Pharmaceuticals Industry |

|

Russian Standard |

|

|

GOST 9941 |

Seamless and Warm-deformed Tubes Made from Corrosion-resistant Steel |

|

Norsok Standard |

|

|

Norsok M - 650 |

Qualification of Manufacturers of Special Material |

|

Norsok M - 630 |

Material Data Sheets and Element Data Sheerts for Piping |

Chemical Requirements (%)

|

தரம் |

UNS Desig |

C |

Mn |

P |

S |

Si |

Cr |

Ni |

Mb |

Ti |

Nb |

Ta |

N |

Vn |

Cu |

Ce |

B |

Al |

Other |

|

TP304 |

S30400 |

0.08 |

2 |

0.045 |

0.03 |

1 |

18.0–20 |

8.0–11 |

. . . |

. . . |

. . . |

. . . |

. . . |

. . . |

. . . |

. . . |

|

|

|

|

TP304L |

S30403 |

0.035 |

2 |

0.045 |

0.03 |

1 |

18.0–20 |

8.0–13 |

. . . |

. . . |

. . . |

. . . |

. . . |

. . . |

. . . |

. . . |

|

|

|

|

TP304H |

S30409 |

0.04 – 0.1 |

2 |

0.045 |

0.03 |

1 |

18.0–20 |

8.0–11 |

. . . |

. . . |

. . . |

. . . |

. . . |

. . . |

. . . |

. . . |

|

|

|

|

TP310S |

S31008 |

0.08 |

2 |

0.045 |

0.03 |

1 |

24.0- 26 |

19.0- 22 |

0.75 |

. . . |

. . . |

. . . |

. . . |

. . . |

. . . |

. . . |

|

|

|

|

TP310H |

S31009 |

0.04 - 0.1 |

2 |

0.045 |

0.03 |

1 |

24.0–26 |

19.0–22 |

. . . |

. . . |

. . . |

. . . |

. . . |

. . . |

|

. . . |

|

|

|

|

TP310H |

S31035 |

0.04 - 0.1 |

0.6 |

0.025 |

0.015 |

0.4 |

21.5–23.5 |

23.5–26.5 |

. . . |

. . . |

0.40- 0.6 |

. . . |

0.20- 0.3 |

. . . |

2.5- 3.5 |

. . . |

0.002- 0.008 |

|

See Spec |

|

TP316 |

S31600 |

0.08 |

2 |

0.045 |

0.03 |

1 |

16.0–18 |

10.0–14 |

2.00–3 |

. . . |

. . . |

. . . |

. . . |

. . . |

. . . |

. . . |

|

|

|

|

TP316L |

S31603 |

0.035 |

2 |

0.045 |

0.03 |

1 |

16.0–18 |

10.0–14 |

2.00–3 |

. . . |

. . . |

. . . |

. . . |

. . . |

. . . |

. . . |

|

|

|

|

TP316H |

S31609 |

0.04 – 0.1 |

2 |

0.045 |

0.03 |

1 |

16.0–18 |

10.0–14 |

2.00–3 |

. . . |

. . . |

. . . |

. . . |

. . . |

. . . |

. . . |

|

|

|

|

TP317 |

S31700 |

0.08 |

2 |

0.045 |

0.03 |

1 |

18.0–20 |

11.0–15 |

3.0–4 |

. . . |

. . . |

. . . |

. . . |

. . . |

. . . |

. . . |

|

|

|

|

TP317L |

S31703 |

0.035 |

2 |

0.045 |

0.03 |

1 |

18.0–20 |

11.0–15 |

3.0–4 |

. . . |

. . . |

. . . |

. . . |

. . . |

. . . |

. . . |

|

|

|

|

TP321 |

S32100 |

0.08 |

2 |

0.045 |

0.03 |

1 |

17.0–19 |

9.0–12 |

. . . |

Ti 5 × (C+N) min, 0.70 max |

. . . |

. . . |

0.1 |

. . . |

. . . |

. . . |

|

|

|

|

TP321H |

S32109 |

0.04 – 0.1 |

2 |

0.045 |

0.03 |

1 |

17.0–19 |

9.0–12 |

. . . |

4(C+N) min; 0.70 max |

. . . |

. . . |

0.1 |

. . . |

. . . |

. . . |

|

|

|

|

TP321H |

S32654 |

0.02 |

2.0-4 |

0.03 |

0.005 |

0.5 |

24.0–25 |

21.0–23 |

7.0-8 |

. . . |

. . . |

. . . |

0.45- 0.55 |

. . . |

0.30-0.6 |

. . . |

|

|

|

|

TP321H |

S33228 |

0.04 - 0.08 |

1 |

0.02 |

0.015 |

0.3 |

26.0–28 |

31.0–33 |

. . . |

. . . |

0.60- 1 |

. . . |

. . . |

. . . |

. . . |

0.05 - 0.1 |

|

0.025 |

|

|

TP321H |

S34565 |

0.03 |

5.0-7 |

0.03 |

0.01 |

1 |

23.0–25 |

16.0–18 |

4.0-5 |

. . . |

0.1 |

. . . |

0.40- 0.6 |

. . . |

. . . |

. . . |

|

|

|

|

TP347 |

S34700 |

0.08 |

2 |

0.045 |

0.03 |

1 |

17.0–19 |

9.0–13 |

. . . |

. . . |

See Spec |

. . . |

. . . |

. . . |

. . . |

. . . |

|

|

|

|

TP347H |

S34709 |

0.04 – 0.1 |

2 |

0.045 |

0.03 |

1 |

17.0–19 |

9.0–13 |

. . . |

. . . |

See Spec |

. . . |

. . . |

. . . |

. . . |

. . . |

|

|

|

|

Alloy 20 |

N08020 |

0.07 |

2 |

0.045 |

0.035 |

1 |

19.0–21 |

32.0–38 |

2.0–3 |

. . . |

See Spec |

See Spec |

. . . |

. . . |

3.0– 4 |

. . . |

. . . |

. . . |

|

|

Alloy 20 |

N08367 |

0.03 |

2 |

0.04 |

0.03 |

1 |

20.0–22 |

23.5–25.5 |

6.0–7 |

. . . |

. . . |

. . . |

0.18–0.25 |

. . . |

0.75 |

. . . |

. . . |

. . . |

|

|

Alloy 20 |

N08028 |

0.03 |

2.5 |

0.03 |

0.03 |

1 |

26.0–28 |

30.0–34 |

3.0–4 |

|

|

|

|

|

0.60–1.4 |

|

|

|

|

|

Alloy 20 |

N08029 |

0.02 |

2 |

0.025 |

0.015 |

0.6 |

26.0–28 |

30.0–34 |

4.0–5 |

|

|

|

|

|

0.6– 1.4 |

|

|

|

|

Heat treatment chart of stainless steel pipe

|

தரம் |

UNS |

Finish |

Heating Temperature |

|

TP304H |

S30409, S30415 |

Cold |

1900 °F [1040 °C] |

|

TP304H |

S30409, S30415 |

Hot |

1900 °F [1040 °C] |

|

TP310H |

S31009 |

|

1900 °F [1040 °C] |

|

TP310H |

S31035 |

|

2160—2280 °F [1180—1250 °C] |

|

TP316H |

S31609 |

Cold |

1900 °F [1040 °C] |

|

TP316H |

S31610 |

Hot |

1900 °F [1040 °C] |

|

TP321H |

S32109, S32615 |

Cold |

2000 °F [1100 °C] |

|

TP321H |

S32109, S32615 |

Hot |

1925 °F [1050 °C] |

|

TP321H |

S32654 |

|

2100 °F [1150 °C] |

|

TP321H |

S33228 |

|

2050—2160 °F [1120—1180 °C] |

|

TP321H |

S34565 |

|

2050—2140 °F [1120—1170 °C] |

|

TP347H |

S34709 |

Cold |

2000 °F [1100 °C] |

|

TP347H |

S34709 |

Hot |

1925 °F [1050 °C] |

|

Alloy 20 |

N08020 |

|

1700—1850 °F [925—1010 °C] |

|

Alloy 20 |

N08367 |

|

2025 °F [1110 °C] |

|

Alloy 20 |

N08028 |

|

2000 °F [1100 °C] |

|

Alloy 20 |

N08029 |

|

2000 °F [1100 °C] |

Tensile requirements of stainless steel pipe

|

தரம் |

UNS Designation |

Tensile Strength, min ksi [MPa] |

Yield Strength, min ksi [MPa] |

Other |

|

TP304 |

S30400 |

75 [515] |

30 [205] |

|

|

TP304L |

S30403 |

70 [485] |

25 [170] |

|

|

TP304H |

S30409 |

75 [515] |

30 [205] |

|

|

TP304H |

S30415 |

87 [600] |

42 [290] |

|

|

TP310S |

S31008 |

75 [515] |

30 [205] |

|

|

TP310H |

S31009 |

75 [515] |

30 [205] |

|

|

TP310H |

S31035 |

95 [655] |

45 [310] |

|

|

TP316 |

S31600 |

75 [515] |

30 [205] |

|

|

TP316L |

S31603 |

70 [485] |

25 [170] |

|

|

TP316H |

S31609 |

75 [515] |

30 [205] |

|

|

TP316H |

S31635 |

75 [515] |

30 [205] |

|

|

TP317 |

S31700 |

75 [515] |

30 [205] |

|

|

TP317L |

S31703 |

75 [515] |

30 [205] |

|

|

TP317L |

S31725 |

75 [515] |

30 [205] |

|

|

TP317L |

S31726 |

80 [550] |

35 [240] |

|

|

TP317L |

S31727 |

80 [550] |

36 [245] |

|

|

TP317L |

S31730 |

70 [480] |

25 [175] |

|

|

TP317L |

S32053 |

93 [640] |

43 [295] |

|

|

TP321 |

S32100 |

75 [515] |

30 [205] |

welded & seamless |

|

TP321 |

S32100 |

75 [515] |

30 [205] |

t = 0.375 in. |

|

TP321 |

S32100 |

70 [480] |

25 [170] |

t > 0.375 in. |

|

TP321H |

S32109 |

75 [515] |

30 [205] |

welded & seamless |

|

TP321H |

S32109 |

75 [515] |

30 [205] |

t = 0.375 in. |

|

TP321H |

S32109 |

70 [480] |

25 [170] |

t > 0.375 in. |

|

TP321H |

S32615 |

80 [550] |

32 [320] |

|

|

TP321H |

S32654 |

109 [750] |

62 [430] |

|

|

TP321H |

S33228 |

73 [500] |

27 [185] |

|

|

TP321H |

S34565 |

115 [795] |

60 [415] |

|

|

TP347 |

S34700 |

75 [515] |

30 [205] |

|

|

TP347H |

S34709 |

75 [515] |

30 [205] |

|

|

Alloy 20 |

N08020 |

80 [550] |

35 [240] |

|

|

Alloy 20 |

N08028 |

73 [500] |

31 [214] |

|

|

Alloy 20 |

N08029 |

73 [500] |

31 [214] |

|

|

Alloy 20 |

N08367 |

100 [690] |

45 [310] |

t = 0.187 in. |

|

Alloy 20 |

N08367 |

95 [655] |

45 [310] |

t > 0.187 in. |