SABS FLANGE

SABS is the flange standard of the South African Bureau of Standards, which is responsible for pipes, fittings, flanges and valve bolts. SABS 1123 flanges include plain, forged or integral cast flanges and weld neck flanges. Although SABS 1123 flanges have become obsolete in recent years, they can still be found if lightweight and economical stainless steel flanges are required. They are mainly used in applications that require hygiene and corrosion resistance. They are available in sizes from ½” to 48”, and they also have different pressure ratings. SABS 1123 flanges can be customized with surface treatments such as rust-proof paint or oil-black paint.

Customers can get SABS 1123 flanges in threaded, screw, forged or plate form, and their production techniques include heat treatment, machining and forging. These flanges can be used in asphalt upgrading units, heavy oil refineries, etc. Due to their corrosion resistance, they can also be used in the metallurgical and shipbuilding industries. These flanges are also available in different face types.

Understanding SABS Flange Standards: Key Specifications and Applications

SABS flanges play a crucial role in ensuring the safety and efficiency of pipeline systems, particularly in industries such as oil & gas, waterworks, and mining. Governed by the South African Bureau of Standards (SABS), these flanges comply with strict manufacturing and performance criteria, making them a trusted choice for industrial applications.

Key SABS Flange Dimensions

SABS flanges are primarily designed according to SABS 1123, which specifies pressure ratings, material types, and dimensional standards. These flanges are available in multiple pressure classes, including PN6, PN10, PN16, PN25, and PN40, ensuring compatibility with various pipeline requirements. Depending on the application, they can be manufactured from carbon steel, stainless steel, or galvanized steel, offering durability and corrosion resistance.

In addition, SABS 1123 flanges come in different types, including weld neck, slip-on, blind, and socket weld flanges, each suited for specific pipeline connections. Their precise engineering ensures leak-free performance and long-term reliability in demanding environments.

Applications of SABS Flanges

SABS flanges are widely used in municipal water distribution, petrochemical processing, mining operations, and industrial piping systems. Their ability to withstand high pressure and harsh operating conditions makes them indispensable for fluid transportation networks. In water treatment plants, for instance, SABS flanges provide secure, corrosion-resistant connections, preventing leaks and ensuring operational efficiency.

For businesses operating in Africa and global markets, sourcing SABS-certified flanges guarantees compliance with safety regulations while enhancing pipeline integrity. By choosing the right SABS flange, industries can optimize system performance, reduce maintenance costs, and ensure long-term reliability.

Looking for high-quality SABS 1123 flanges? Connect with Yulong today to get the best solutions for your industrial needs!

How to Select the Right SABS Flange for Your Pipeline System

Choosing the right SABS flange is crucial for ensuring a secure, efficient, and long-lasting pipeline system. Whether for waterworks, mining, or industrial applications, selecting the right flange can prevent leaks, reduce maintenance costs, and improve overall system performance. Yulong, a trusted name in pipeline solutions, provides high-quality SABS 1123 flanges designed for durability and reliability.

1. Understand SABS 1123 Flange Standards

SABS flanges are classified based on pressure ratings, including PN10, PN16, PN25, and PN40, each suited for different applications. Ensuring compliance with SABS 1123 standards guarantees compatibility with South African pipeline systems and enhances safety.

2. Choose the Right Material

Material selection is key to corrosion resistance and strength. Yulong offers SABS flanges in carbon steel, stainless steel, and galvanized steel, ensuring optimal performance in varying environments. For water treatment and chemical processing, stainless steel is ideal, while carbon steel suits high-pressure applications.

3. Consider the Connection Type

Different flange types serve different needs. Yulong provides welding neck, slip-on flange for sale, blind flange, and lap joint flanges, each suited for specific installation requirements. Selecting the correct connection type ensures a leak-proof and high-pressure-resistant system.

4. Ensure Supplier Certification

To guarantee quality, always source from certified SABS flange manufacturers like Yulong. Our precision-engineered flanges meet international standards, ensuring long-term durability and cost efficiency.

5. Optimize Cost Without Compromising Quality

While pricing is a key factor, compromising on quality can lead to long-term failures. Yulong provides competitive pricing on SABS-certified flanges without sacrificing performance, ensuring value for every investment.

For reliable, high-quality SABS 1123 flanges, trust Yulong. Contact us today for expert guidance and premium pipeline solutions! 🚀

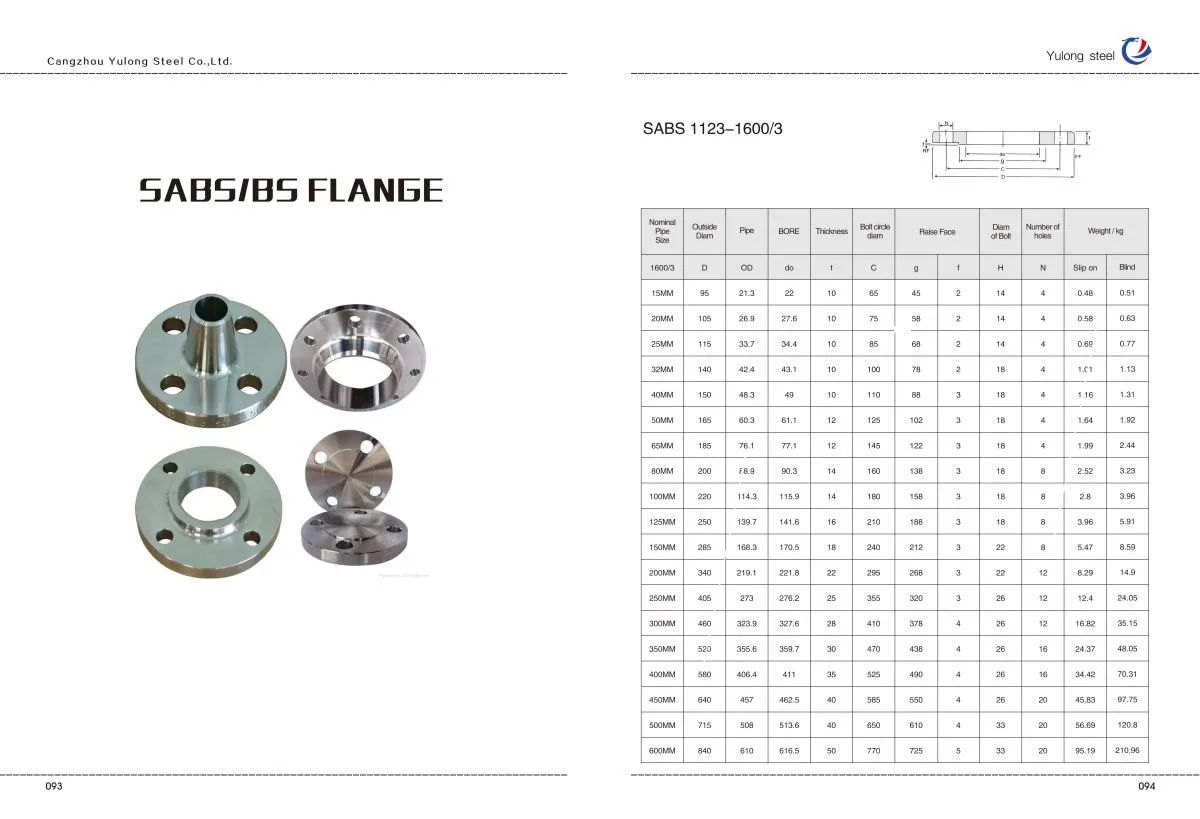

SABS Flange Dimensions

SABS Flange FAQs

What is an SABS flange? |

| An SABS flange is a type of flange manufactured according to the South African Bureau of Standards (SABS) 1123 specifications. It is commonly used in pipeline systems for waterworks, mining, and industrial applications in South Africa and neighboring regions. |

What materials are SABS flanges made from? |

| SABS flanges are typically manufactured from: Carbon Steel – Cost-effective and strong, ideal for general industrial use Stainless Steel – Highly corrosion-resistant, used in water treatment and chemical industries Galvanized Steel – Coated for enhanced rust protection, commonly used in outdoor applications |

How do I choose the right SABS flange for my application? |

| Consider the following: Pressure rating – Ensure it matches your system’s requirements Material – Select corrosion-resistant materials based on the operating environment Flange type – Choose the right connection method for installation and maintenance needs |

Where can I buy certified SABS flanges? |

| For high-quality, SABS-certified flanges, trust Yulong. We provide durable SABS 1123 flanges tailored to meet your industry needs. Contact us today for expert advice and competitive pricing! 🚀 |