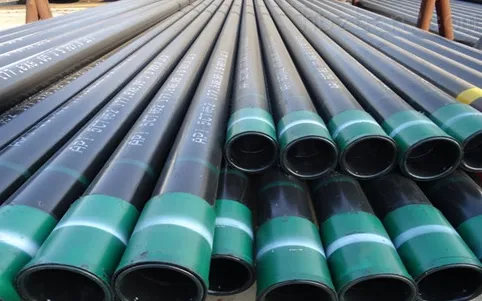

API 5CT/API 5CT Seamless Tube/ API 5CT J55 Casing Pipes /API 5CT K55/API 5CT N80/API 5CT P110 Oil Well Drilling Tube Manufacturer/Oilfield Casing Pipes stockist china

The API 5CT standard mainly covers a variety of steel pipe materials used in the oil and gas industry.

Carbon steel is one of the commonly used materials. For example, J55 steel grade, it contains a certain amount of carbon (general carbon content of about 0.28%-0.34%), manganese (about 0.60%-0.90%) and other elements. Carbon can improve the strength of steel pipes, and manganese helps to improve the toughness and hardenability of steel. The steel pipe of this material is suitable for general oil well casing environment, and its strength can withstand a certain pressure in the oil well and the force of the external formation.

The K55 steel grade is similar to the J55, but there are some subtle differences in composition and performance. It has a slightly lower carbon content, usually between 0.20% and 0.28%, and a manganese content between 0.30% and 0.60%, and is used in some oil well environments where strength requirements are not extremely high, but toughness and corrosion resistance are certain requirements.

There are two types of N80 steel grade, one is N80-1 and the other is N80-Q. N80-1 is a normalizing steel, its alloying element content is relatively high, such as chromium (Cr), molybdenum (Mo) and other elements have a small amount of addition, chromium can improve the oxidation resistance and corrosion resistance of the steel pipe, molybdenum can improve the thermal strength of steel. N80-Q is a quenched and tempered steel, through this heat treatment, its strength and toughness can be better balanced, widely used in deep Wells, high pressure oil Wells and other harsh mining environment.

P110 steel grade is a high-strength steel pipe material, containing chromium (about 1.00%-1.25%), molybdenum (about 0.25%-0.35%) and other alloying elements. The addition of chromium molybdenum alloy makes the steel pipe in high temperature and high pressure environment can still maintain good mechanical properties, can withstand extremely high internal pressure and external extrusion pressure, often used in deep oil Wells and ultra-high pressure oil Wells casing.

|

API 5CT CASING PIPE SPECIFICATIONS |

||

|

API Standard |

: |

API Specification 5CT |

|

API 5CT Casing Pipe Grade |

: |

J55, K55, N80, L80, P110, C90, C95, T95, Q125 Pipes |

|

API 5CT Casing Pipe Type |

: |

Electric Resistance Welded (ERW) |

|

API 5CT Casing Pipe Size |

: |

NPS 1 TO NPS 24 [DN25 to DN 600], with nominal (average) wall thickness as given in ASME B 36.10M or as client's requirement. |

|

API 5CT Casing Pipe Outer Diameter |

: |

1-24 inches( 33.4-609.6mm) |

|

API 5CT Casing Pipe Thickness |

: |

3mm - 12mm |

|

API 5CT Casing Pipe Length |

: |

Min 3 Meters, Max18 Meters or according to Client's requirement |

|

API 5CT Casing Pipe Surface Treatment |

: |

Normally bare or black vanish, 2PE/FBE/3PE Coated |

|

API 5CT Casing Pipe Usage |

: |

API 5CT steel pipes for petroleum and natural gas transportation |

|

API 5CT Casing Pipe Testing |

: |

· Product analysis · Tendile test · CVN Impact test · Drop-weight tear test · Full section bend test · Guided-bend test · Flattening test · Hardness test · Macrographic and metallographic tests · Hydrostatic test |

API 5CT Casing Tubing Features

- The surface of thread of coupling and API 5CT Casing Tubing should be smooth without any tear, burr or other defects that may have a negative impact on the strength and close connection.

- API 5CT Casing Tubing is offered with a free length range from 8m to 13m on basis of the SY/T6194-96 norm. However, it is also available no less than 6m length and its quantity should be no more than 20%.

- Deformations which mentioned above are not allowed to appear on the outer surface of API 5CT Casing Tubing coupling.

- Any deformation such as crease, separation, hairline, crack or scab is not acceptable on both inner and outer surfaces of the product. All these defects should be completely removed, and the removed depth must not exceed 12.5% of nominal wall thickness.

API 5CT Casing Tubing Steel Color Code

|

Nimi |

J55 |

K55 |

N80-1 |

N80-Q |

L80-1 |

P110 |

|

Casing |

a bright green band |

two bright green bands |

a bright red band |

a bright red band + a green band |

a red band + a brown band |

a bright white band |

|

Kytkentä |

entire green coupling + a white band |

entire green coupling |

entire red coupling |

entire red coupling + a green band |

entire red coupling + a brown band |

entire white coupling |